JimInOz

··Melbourne AustraliaI'm servicing a Valjoux 7733 based Tissot 20700 chrono and so far it's been fairly standard and no surprises.

However...

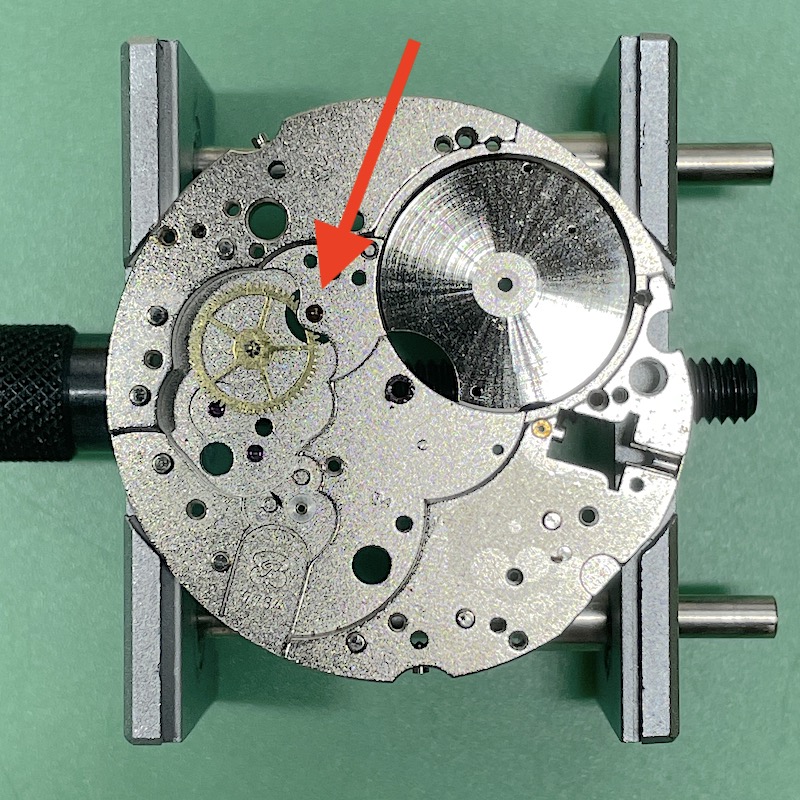

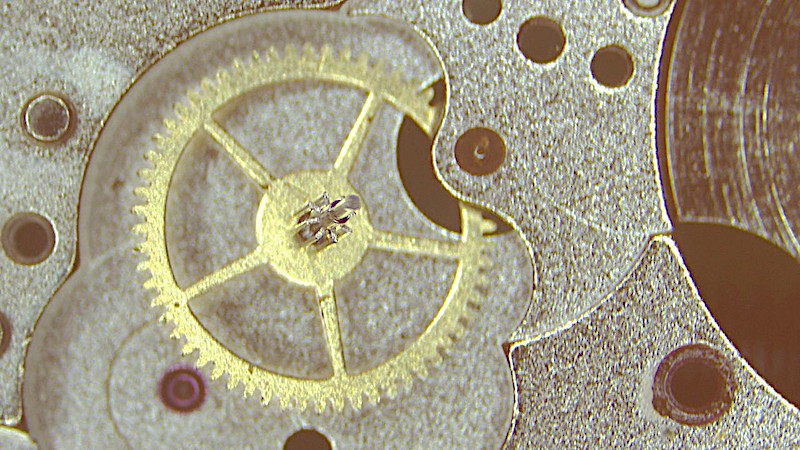

I found a basic tech guide on the webs which was quite helpful, but when it gets to removing the chrono driving wheel is simply states: "Remove the driving wheel No. 8060, using a suitable tool."

"Suitable tool" can cover a multitude of options, depending on the mentality of the user, so any watchmakers with experience removing this component?

And what "suitable tool" was used?

The offending item.

The top of the wheel arbor has a groove that may be to provide a grip for a "lifter". The wheel appears to be pressed onto the fourth wheel pivot.

Any guidance appreciated.

@Archer, @ChrisN, @Deafcon, @Canuck, and anyone else who would like to advise.

However...

I found a basic tech guide on the webs which was quite helpful, but when it gets to removing the chrono driving wheel is simply states: "Remove the driving wheel No. 8060, using a suitable tool."

"Suitable tool" can cover a multitude of options, depending on the mentality of the user, so any watchmakers with experience removing this component?

And what "suitable tool" was used?

The offending item.

The top of the wheel arbor has a groove that may be to provide a grip for a "lifter". The wheel appears to be pressed onto the fourth wheel pivot.

Any guidance appreciated.

@Archer, @ChrisN, @Deafcon, @Canuck, and anyone else who would like to advise.