Hi Jim

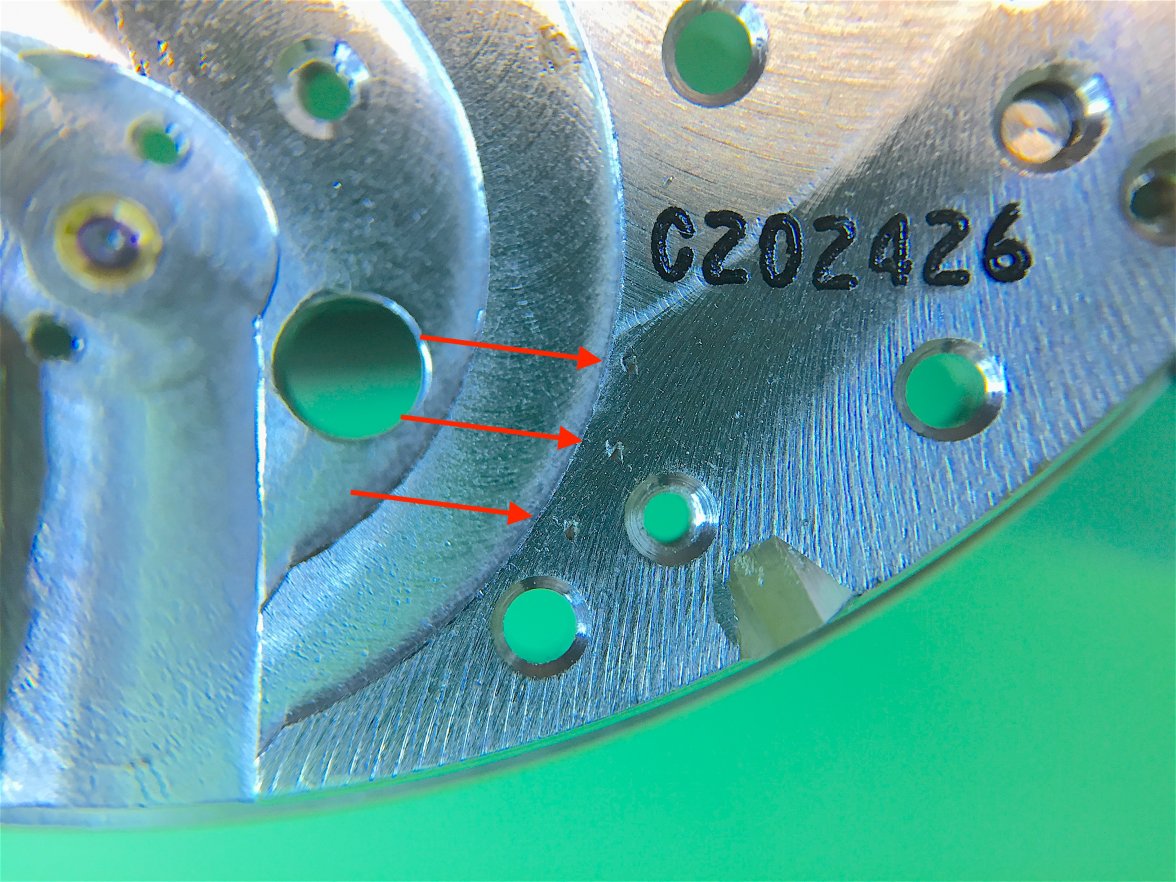

Ah, the joys of watchmaking and finding the "tricks" that other people have done

🙄

First, and it seems a silly question, but you do have the cap jewels in before checking end shake? If not, it will be huge, obviously, but we all do daft things sometimes.

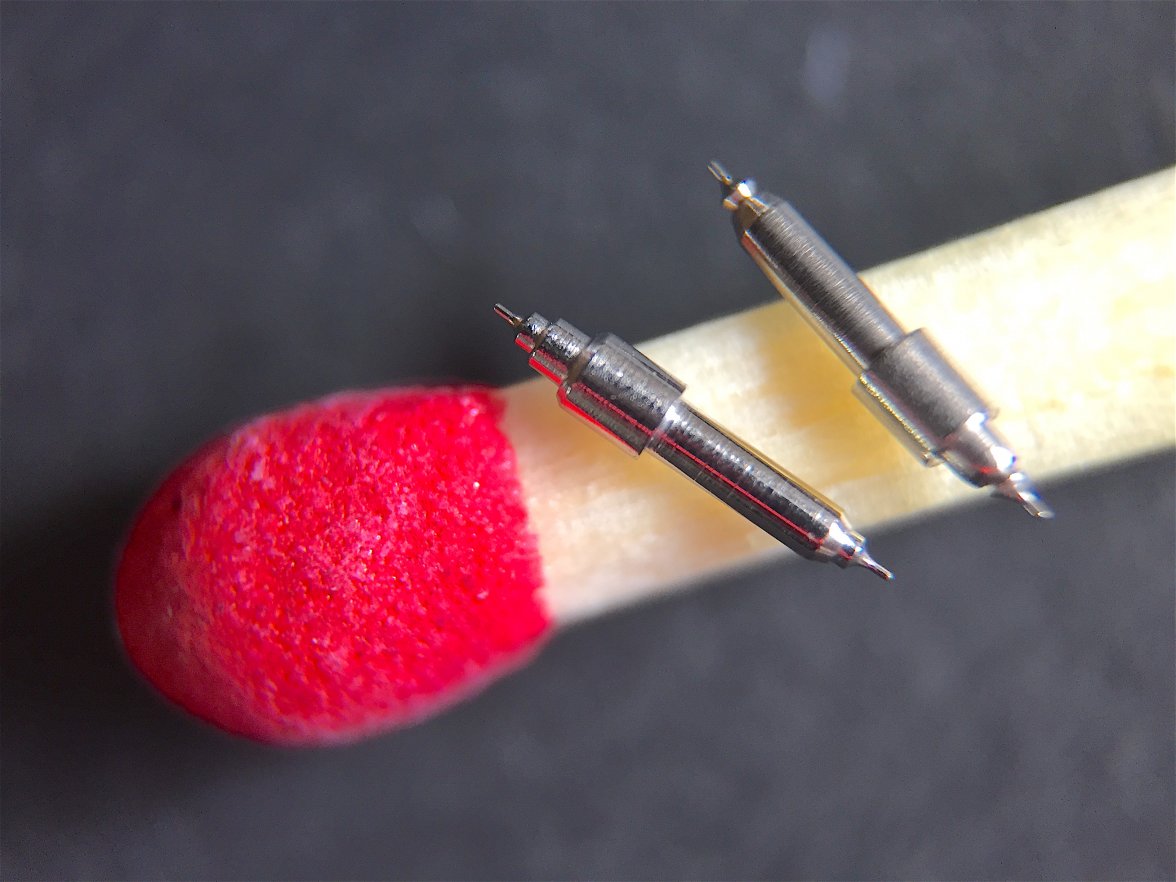

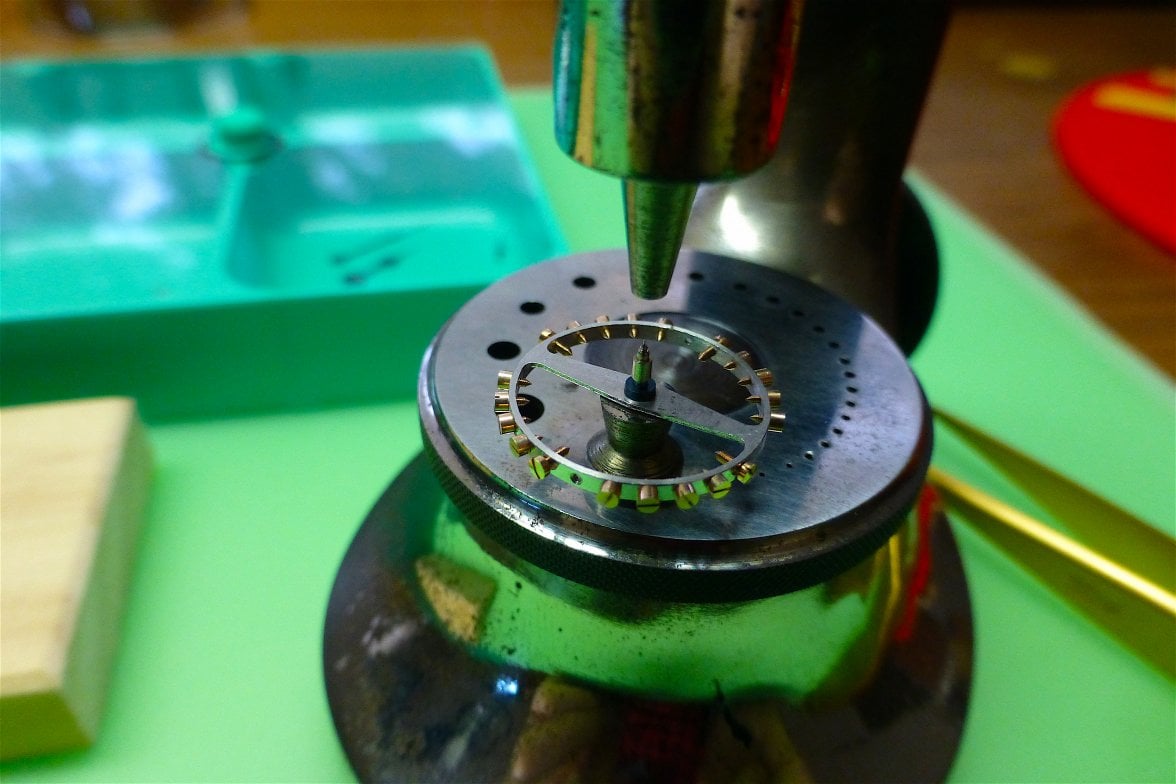

If you really have 0.20/0.25 mm then it's about ten times what you want so, far too much. I'd measure the lengths of the two staffs you have and see if the other is a little longer as it would be easier to replace that staff again than anything else. At least with these, staff removal is easy so, you've lost nothing by fitting it to the wheel.

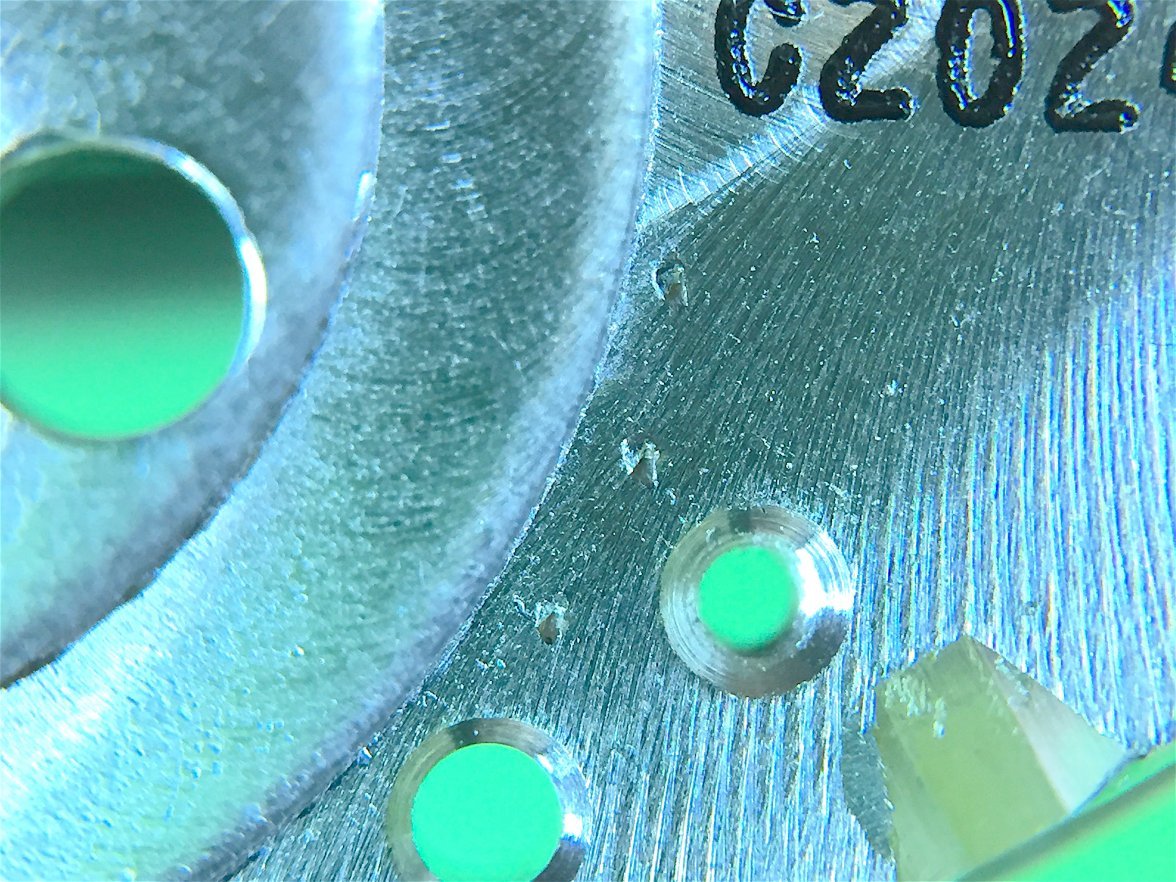

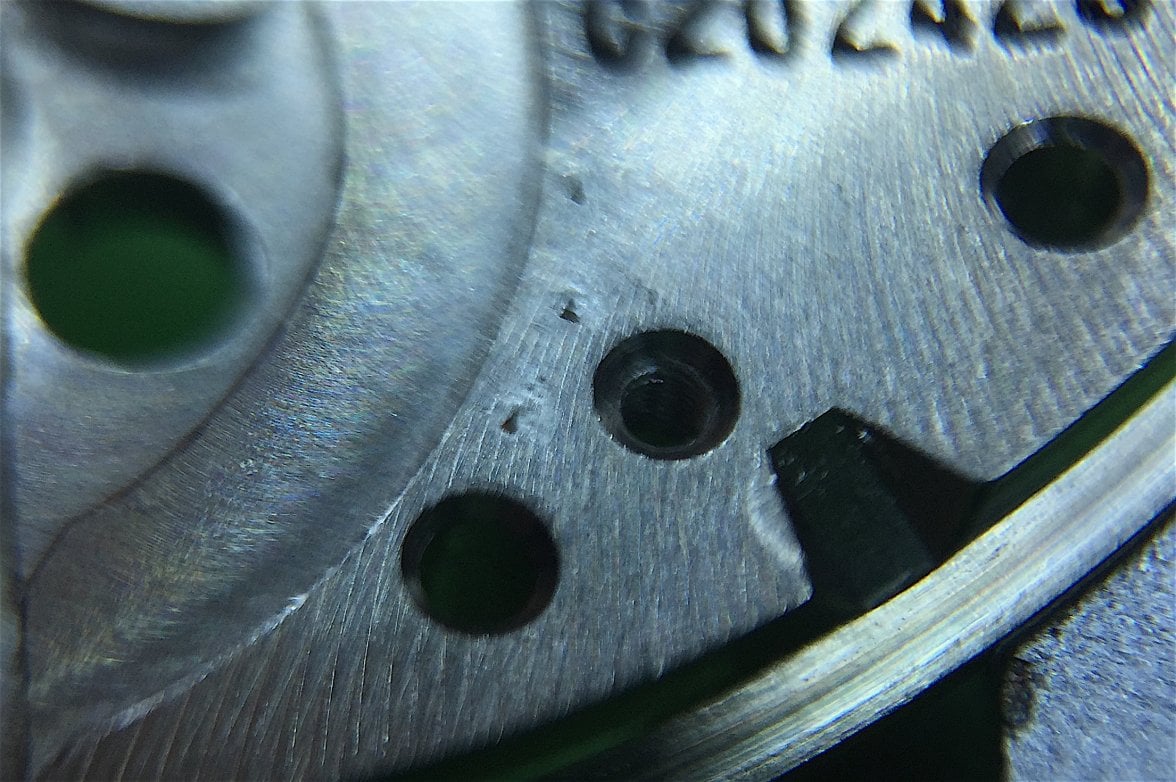

Possibly, the previous watchmaker couldn't get the correct staff so fitted a bestfit item and had to fix the end shake. Pigs ears is not the preferred way but, it's quick and dirty and obviously worked in this location for them. I've seen a piece of wax paper cut to fit under the balance cock which again is not ideal! It seems anything goes with some people. Out of interest, Poljot use factory steel shims to adjust endshake which fit under the balance cock in the same way as the paper did but, usually with a shock system, you'd move the lower jewel as you're proposing. I am not sure with the watch that you have if there is any adjustment in the lower cap jewel but it seems unlikely.

So, way forward for me would be:

1. Check the cap jewels are properly seated.

2. Fit the fork and this should have very little end shake.

3. Fit the balance and it should have a little more or about the same as the fork.

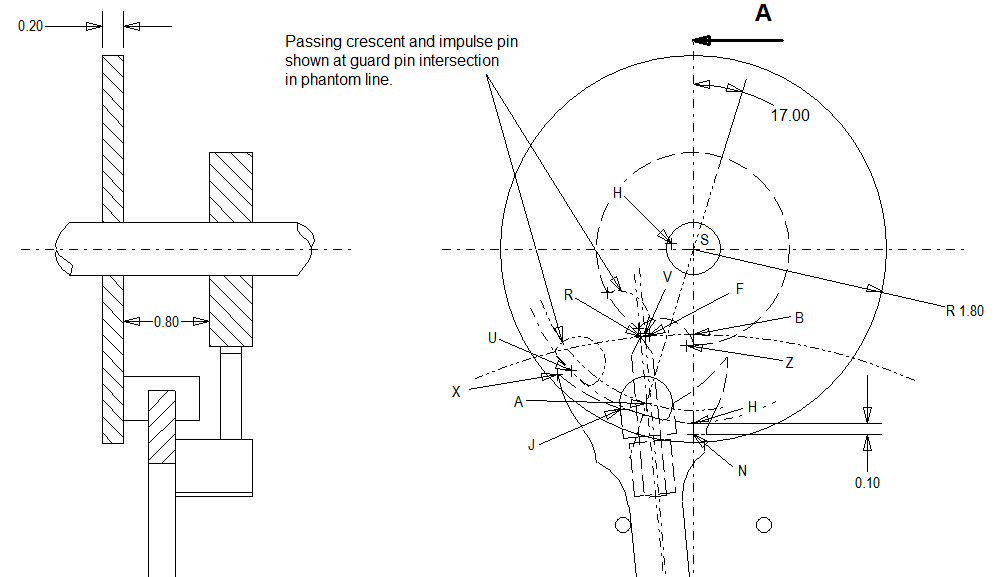

4. Have a look from the side where the fork end is in relation to the ruby pin - it should be more or less central in the height of the pin.

5. At the same time, see if the guard pin on the fork is in the middle of the safety roller - it should be.

6. Move the balance up and down and see if you still meet items 4 and 5.

7. Based on that, you can see which side of the shake needs to be reduced - for example, if you can move the balance up by adjusting the lower cap jewel, you may find that now the fork is clashing with the roller table and that's not going to work. Probably, you'll end up removing the pigs ears as that is what is not as designed.

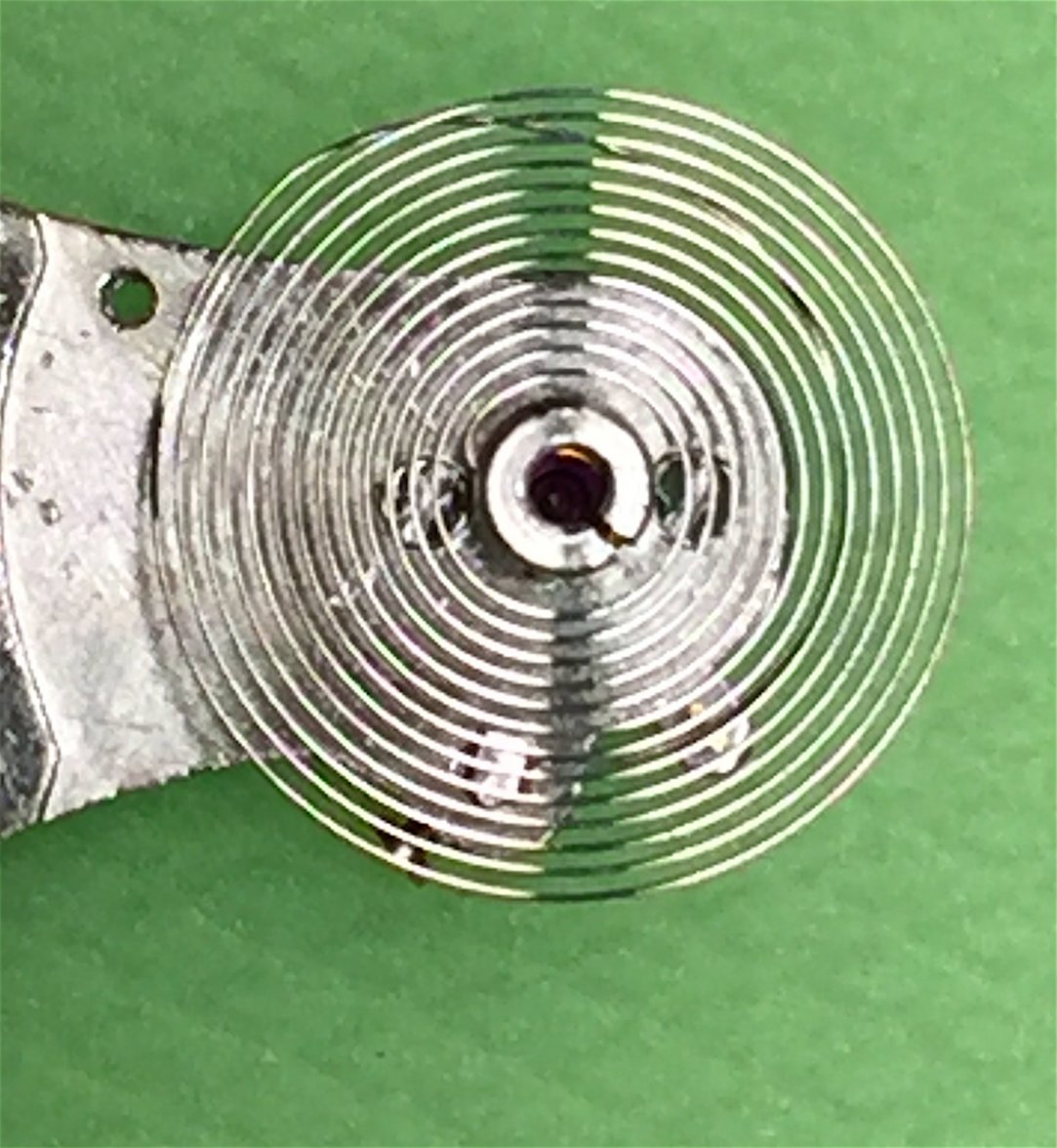

I know you can read this so, here's a picture below showing what I mean. On the section is the main roller table at 0.2 mm thick with the ruby pin showing to the right of that and the fork is exactly mid height of the ruby. The guard pin on the fork is exactly mid height of the safety roller - well, that's where I drew them

😁 but, that's what you're looking for.

Good luck!

Cheers, Chris