Hi Jim,

If the lift angle is right, the balance amplitude is low. Can't recall if you replaced the mainspring, so if this has a blued steel spring in it still, I would replace that with a white alloy spring as the blued steel springs are often very set.

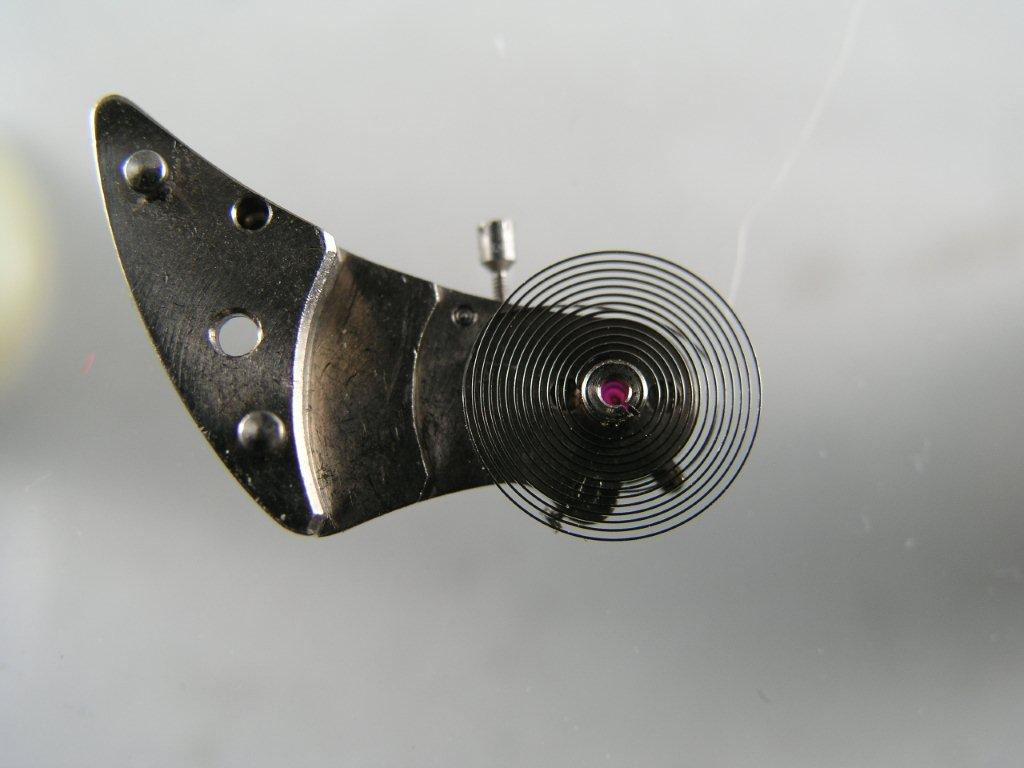

So what checks/adjustments of the balance spring have you done so far? I typically do my initial checks and adjustments right after cleaning, so I lubricate the balance jewels and mount the balance on the main plate - this allows me a clear view all around the balance spring:

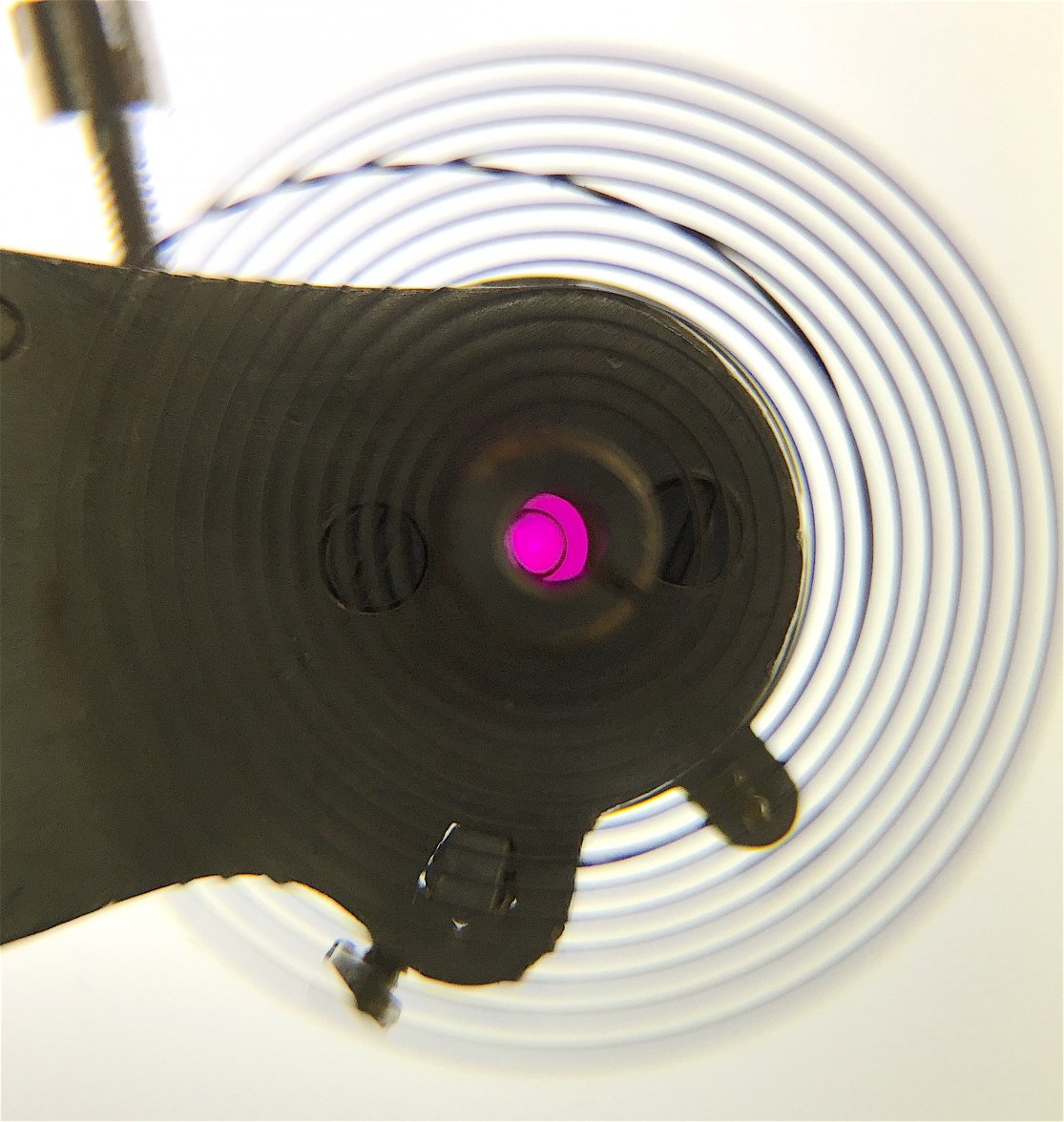

I check to make sure that the coils of the spring are all concentric, evenly spaced, that the spring is flat, and that the portion of the spring that goes through the regulating pins is centered between those pins. In a watch with the ETACHRON system, I also set the distance between the regulating pins. These are the basic adjustments I do on every watch, and all this must be done before proceeding. From there the timing machine guides my next steps.

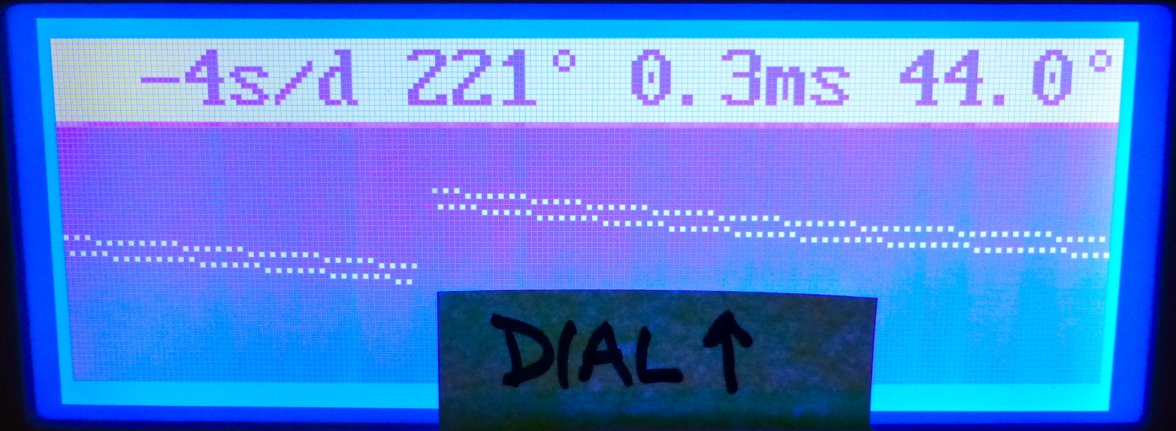

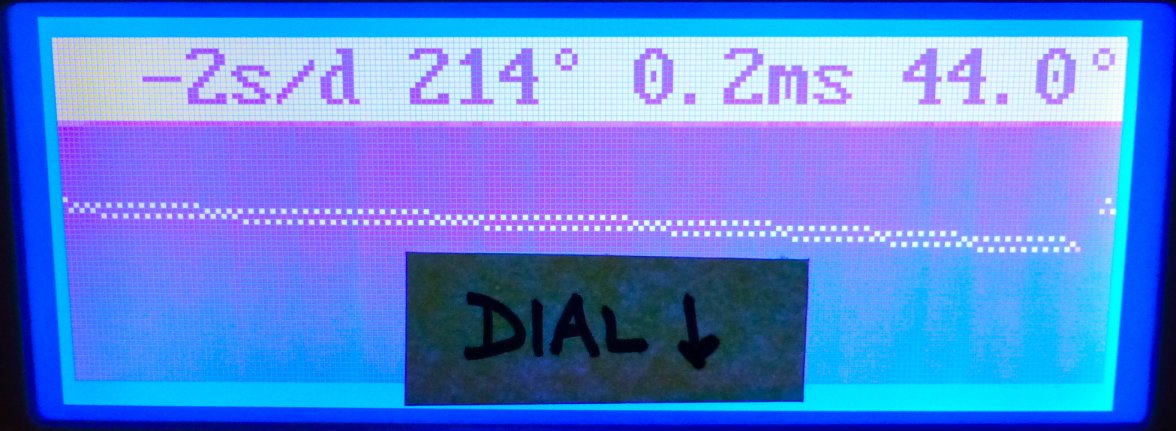

I then look at the readings for any really off measurements, so make sure the amplitudes all look as they should, and I don't have any major differences between the 4 vertical measurements, or between the 2 horizontal. I then look at the timing numbers for any wild readings, but also to note the difference between the average of the 2 horizontal readings, and the average of the 4 vertical readings. If the averages are significantly different, then adjustments to the regulating pins may be required.

Generally speaking, if the average of the vertical readings is slower than the horizontal, as in your case, then the pins are too far apart. If the average of the vertical is faster than the horizontal, the pins are too close together.

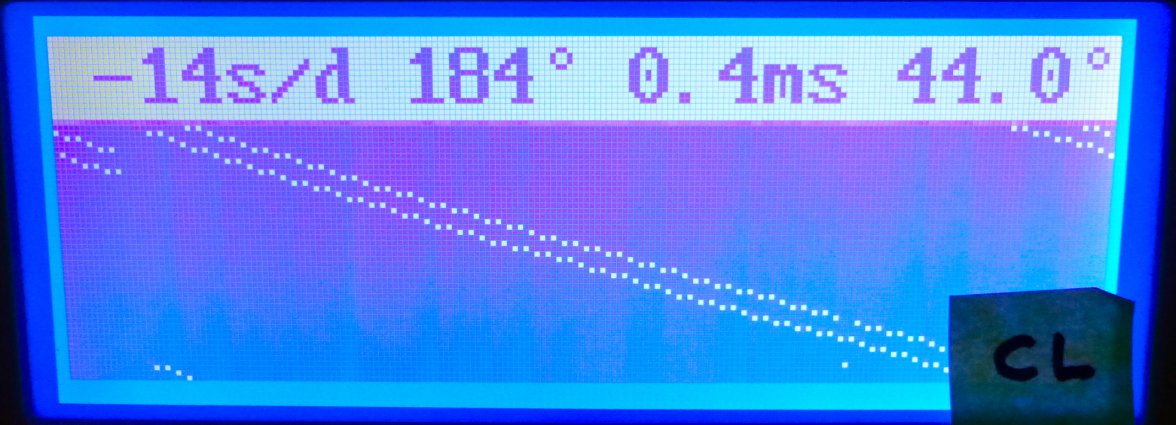

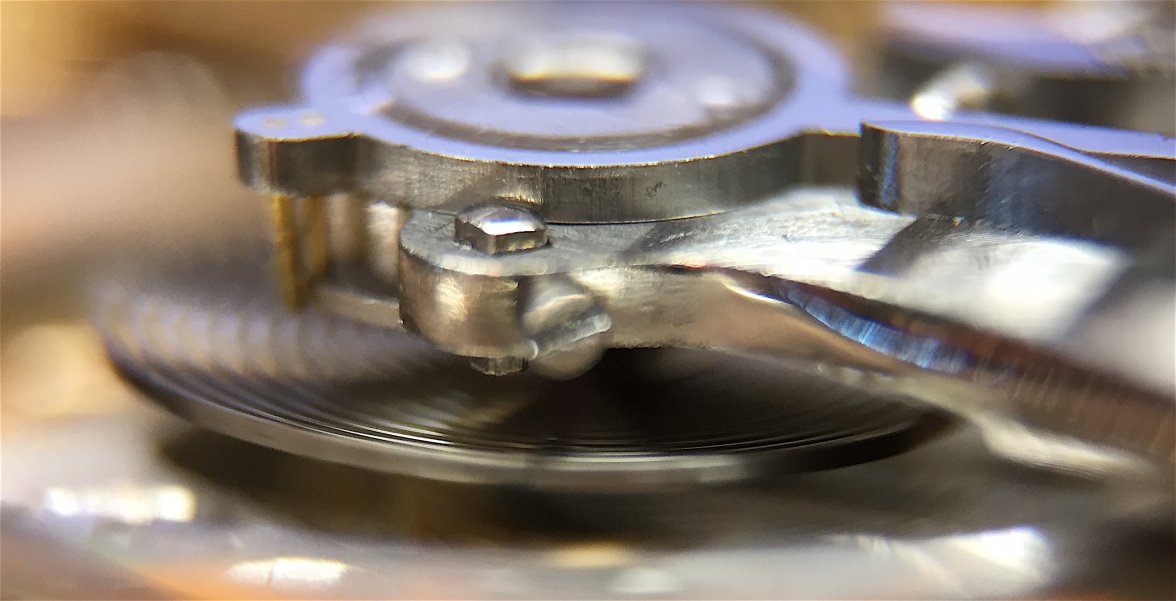

Now when adjusting the pins, you need to keep them parallel. Not having the parallel is a common source of dial up to dial down timing errors. This is an extreme example of what I mean from a Tudor I'm working on that was a complete mess - regulating pins as the watch was received:

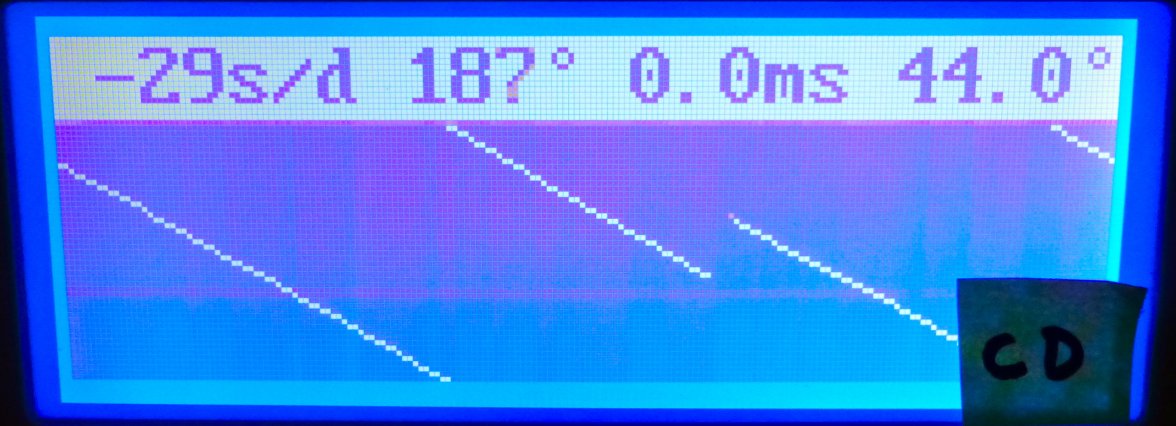

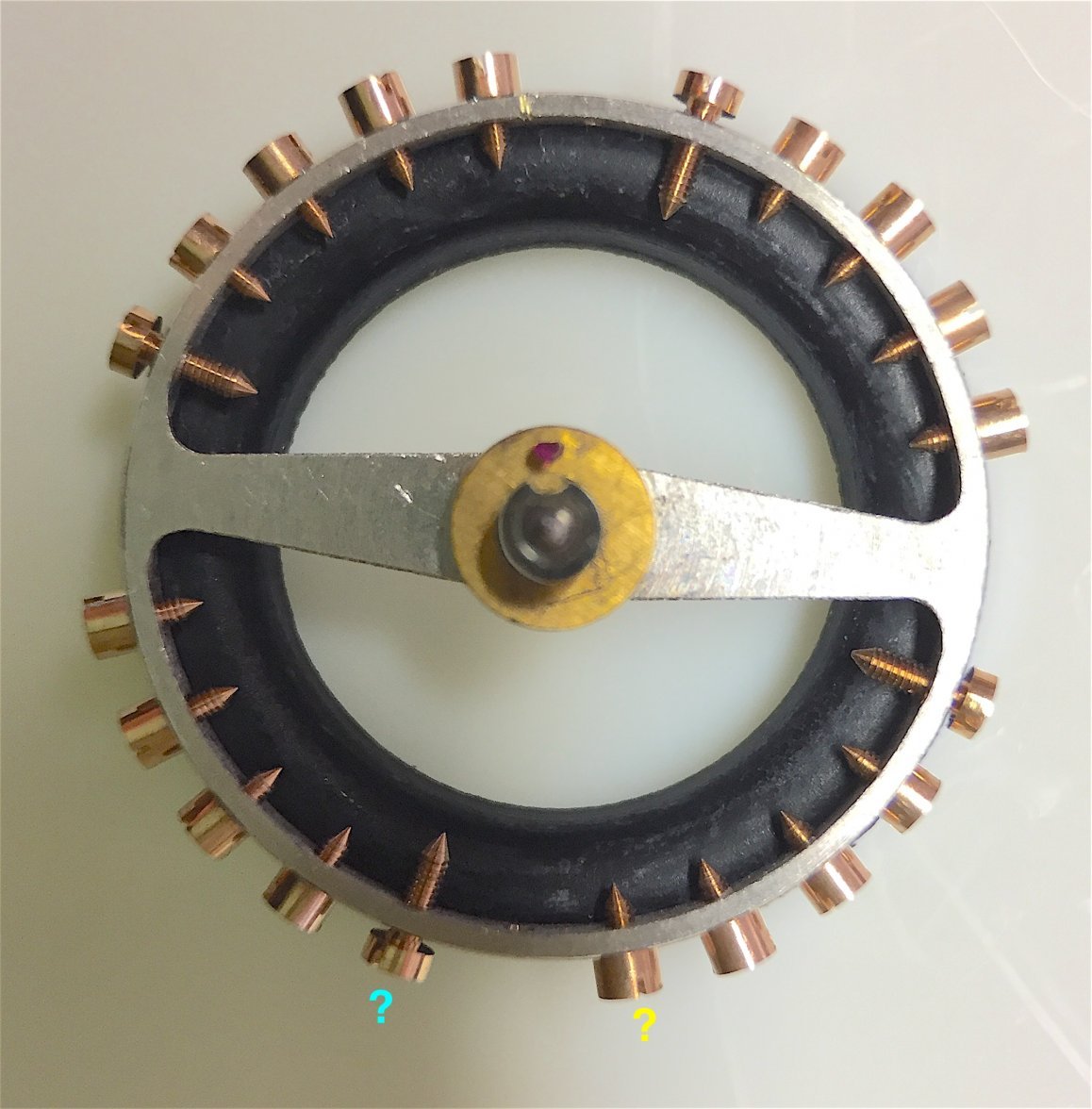

And after adjusting:

As a rule of thumb I typically want the pins to be spaced so that there is about the thickness of the balance spring clearance on either side, and then adjust from there based on results again.

Cheers, Al