ErichKeane

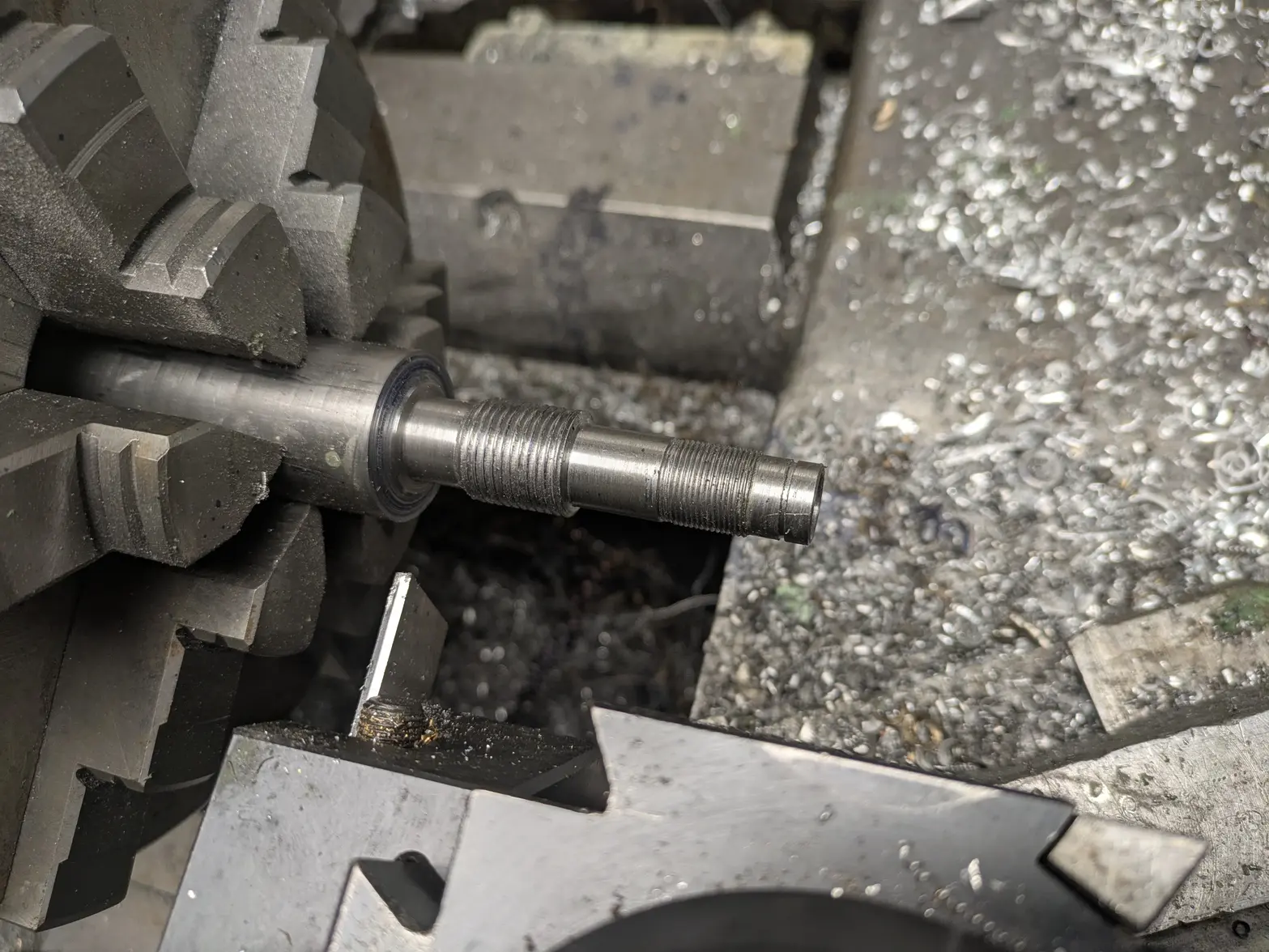

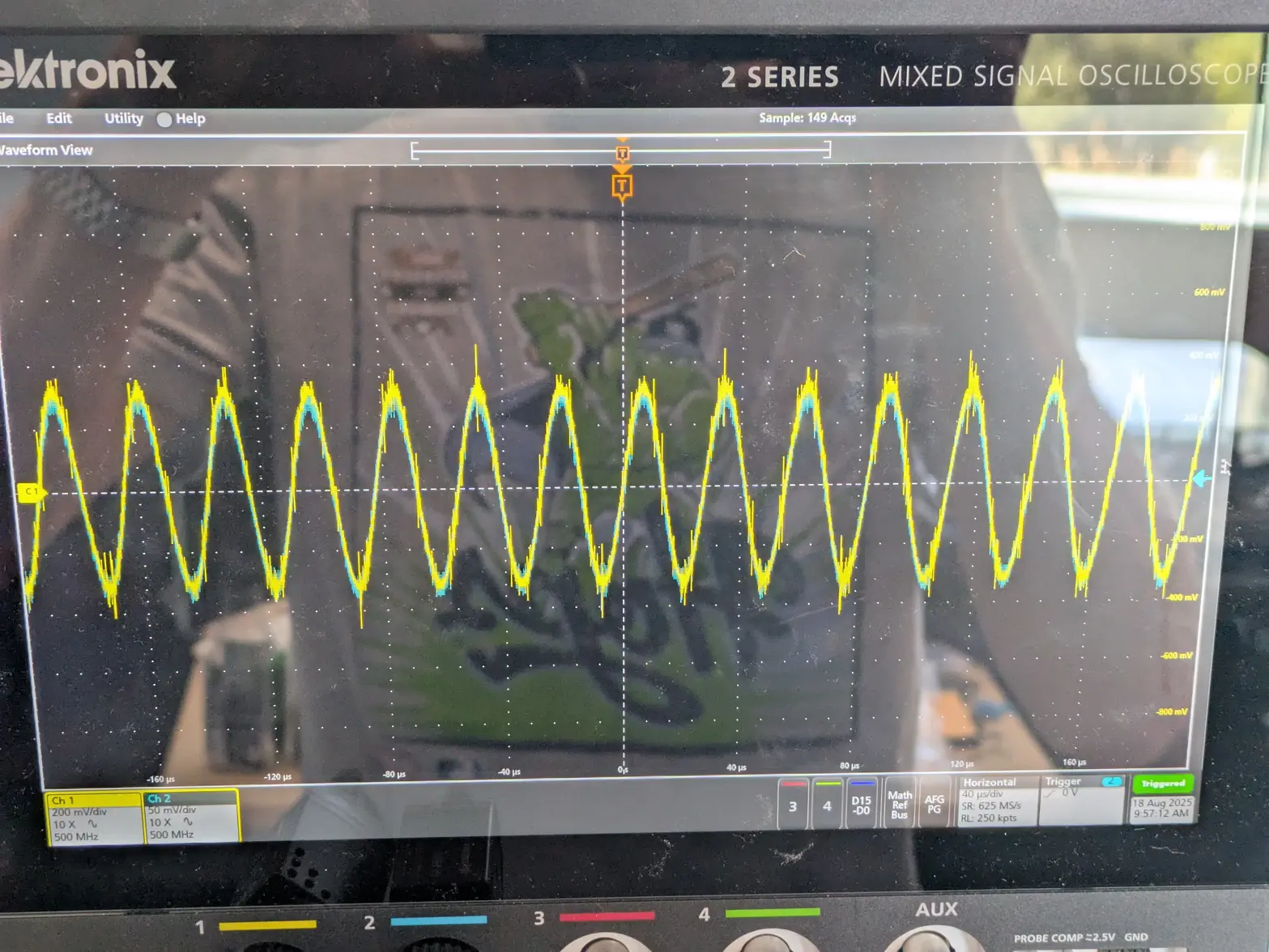

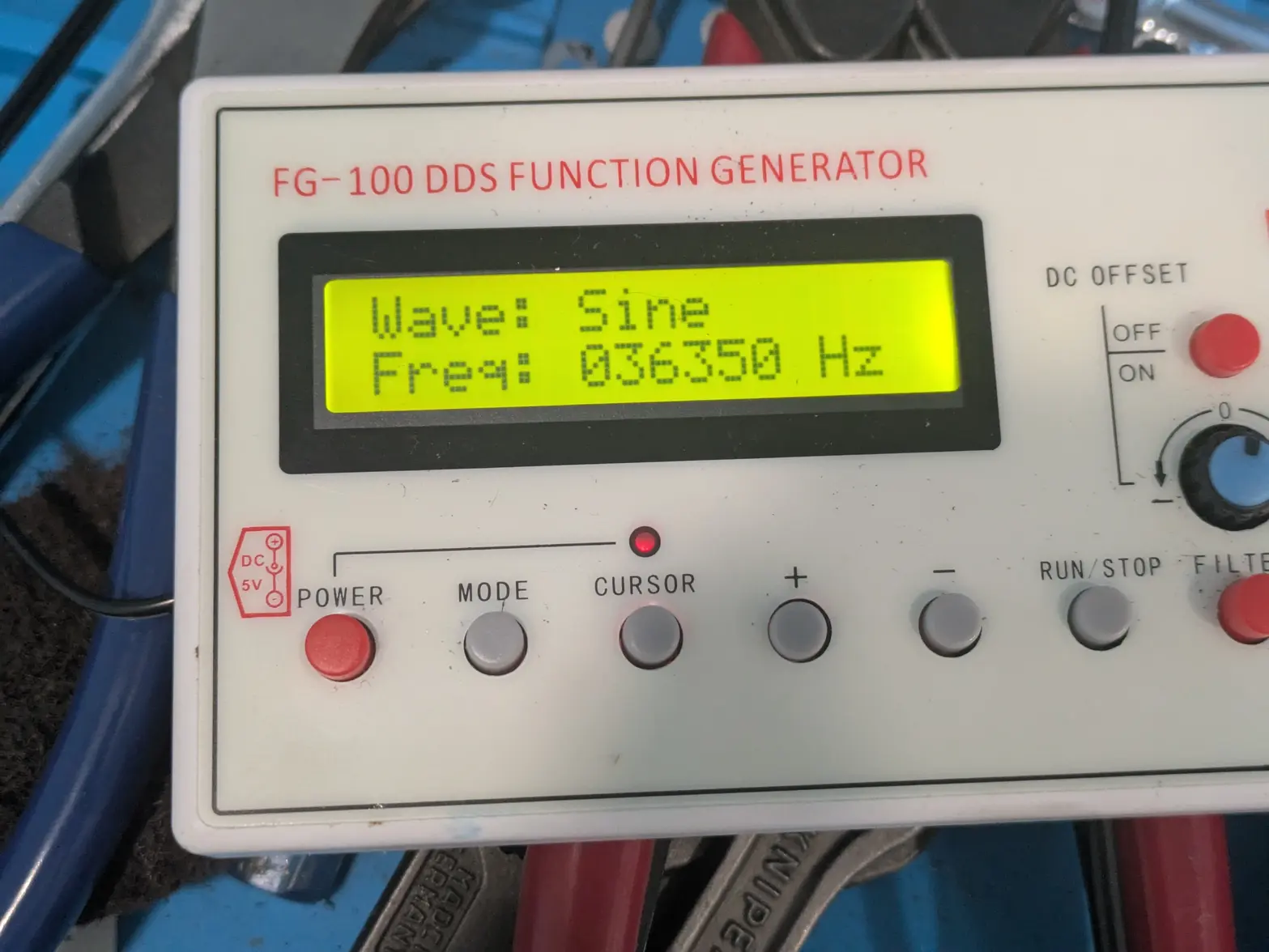

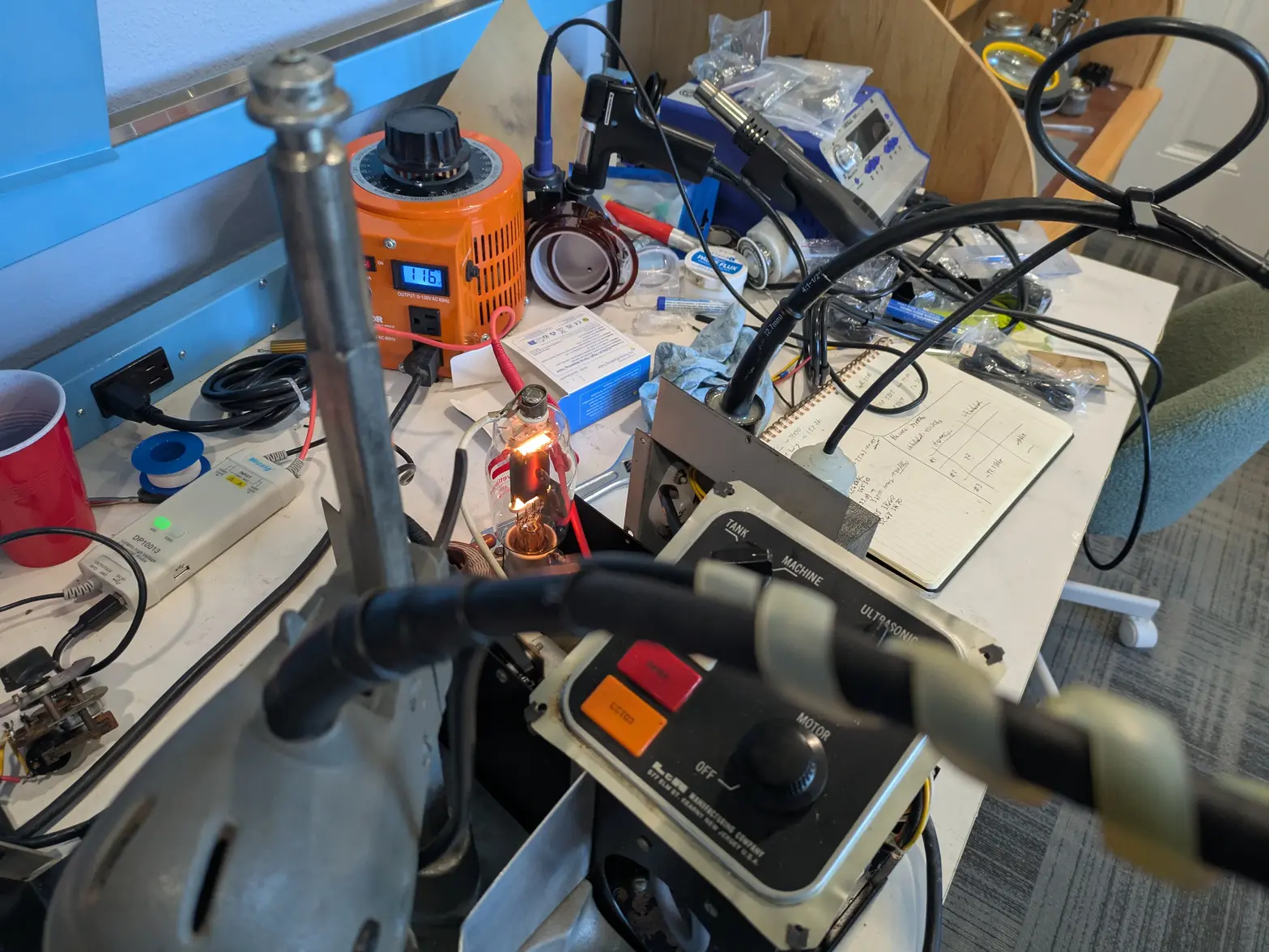

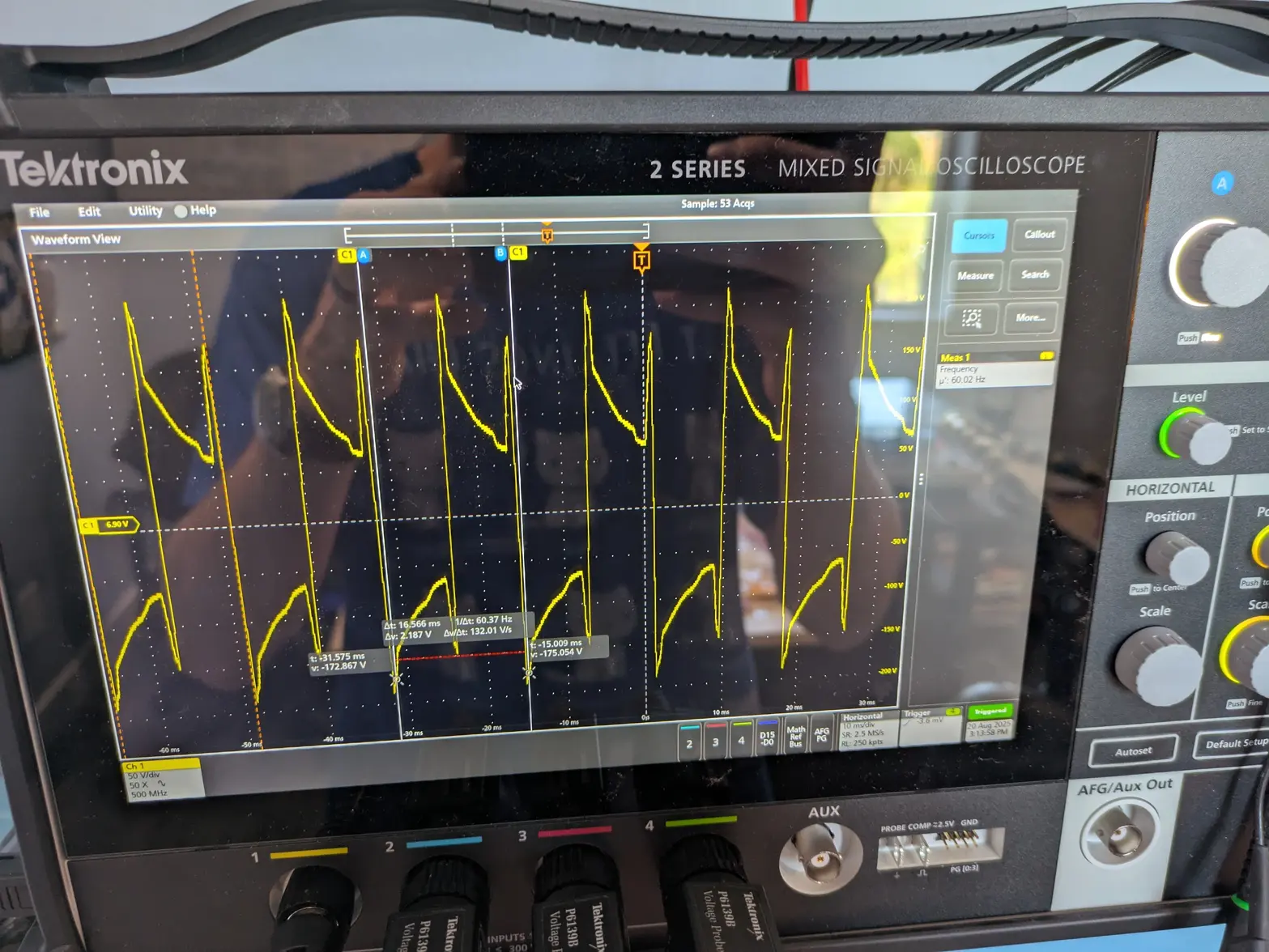

·No good pictures today, but I got the whole transducer assembled and tried to test it. What you do do is have a signal generator run a sine wave through it and a resistor, then use the oscilloscope to measure the frequency input and the current-only (via the resistor) and see when the two line up/maximize the current use, which should be your point of resonation.

I can do this test pretty easily/predictably with the off-the-shelf transducers, they work fine.

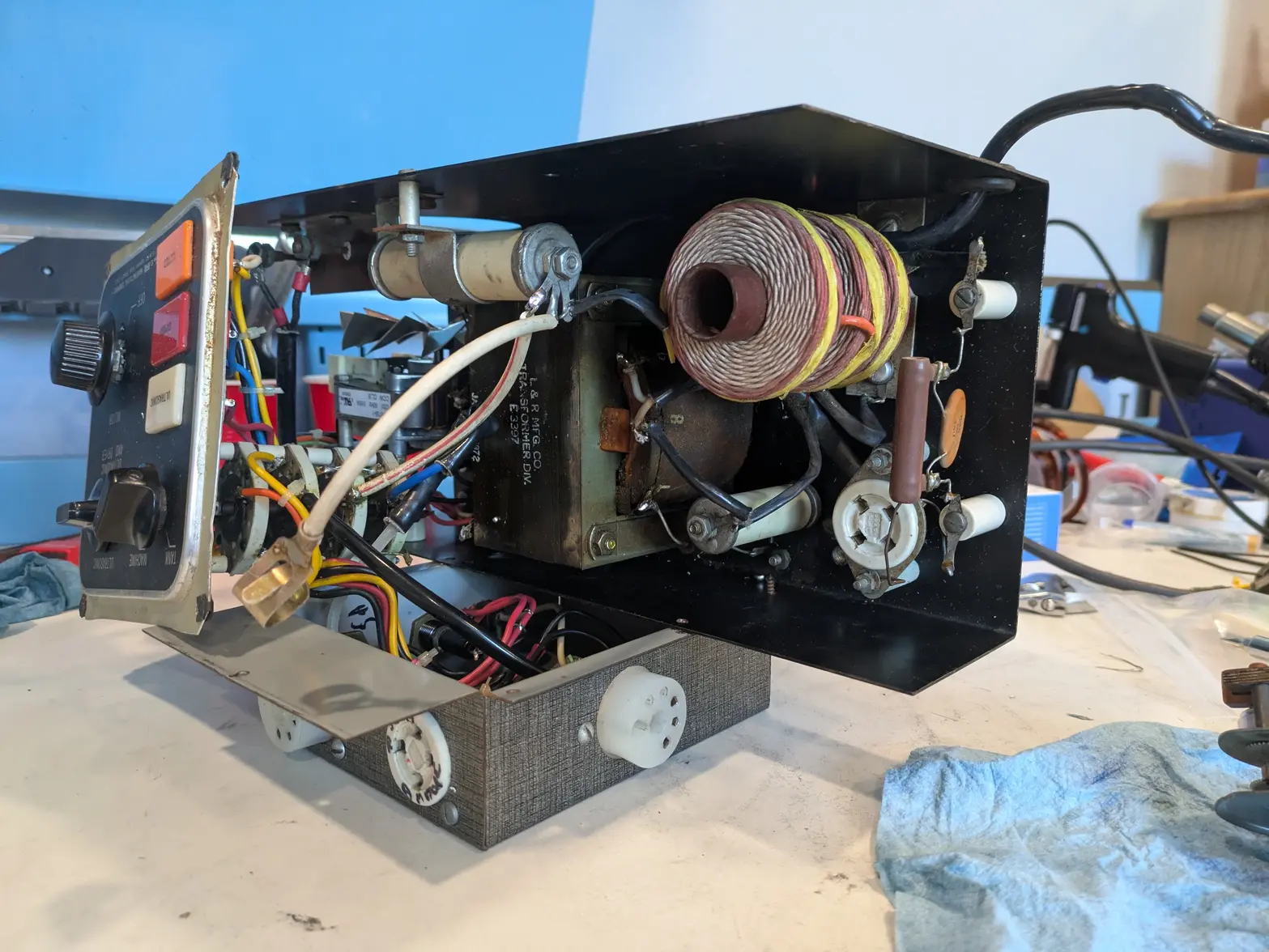

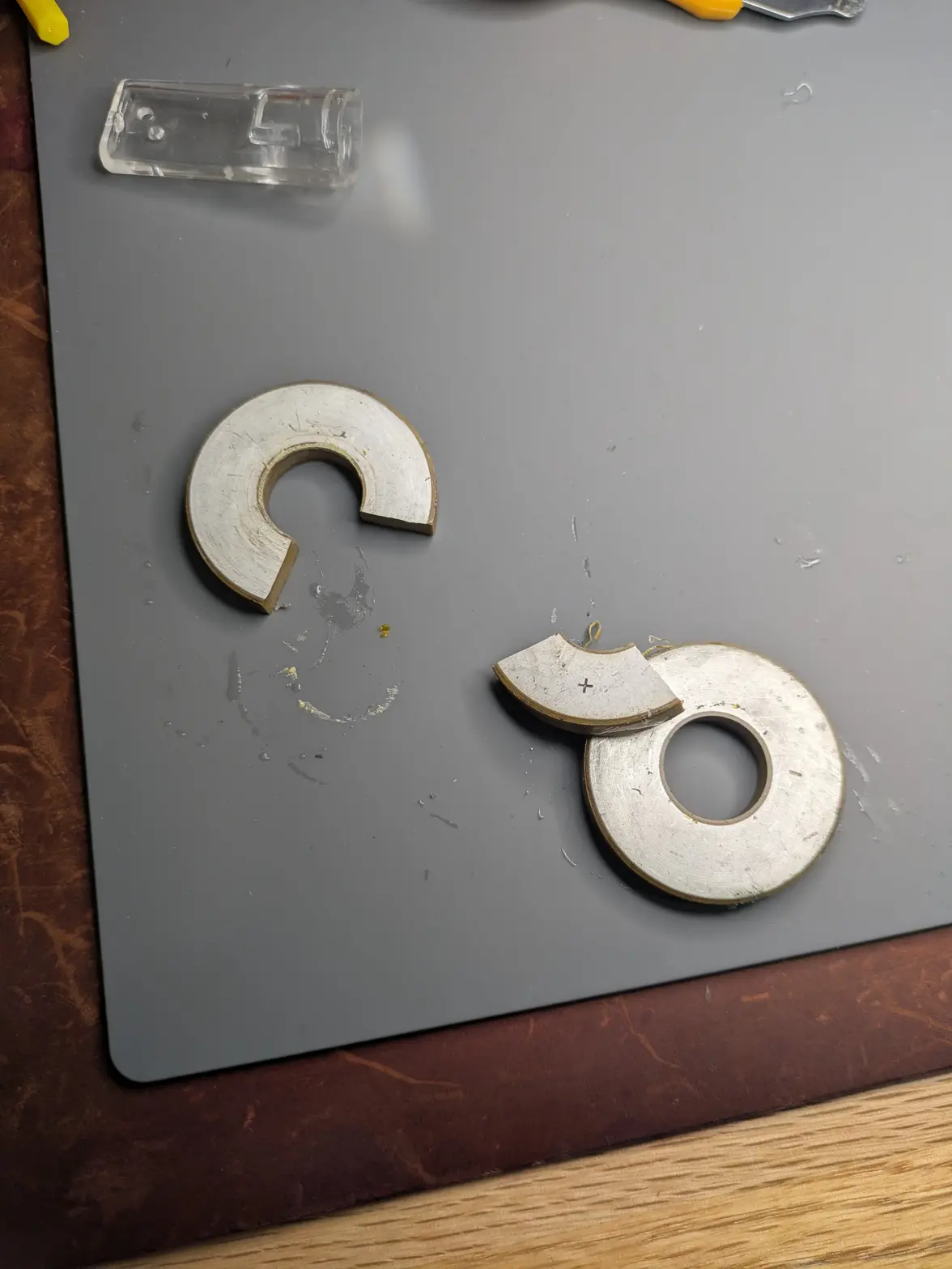

However, I'm not really getting anything like that at a reasonable frequency (my measurement was 182khz!), and shortening it didn't seem to change much. So the 'horn'/'can' isn't really working as a resonating horn, and I'm not sure why. I tried shortening it a bunch (down to ~25.75mm horn, compared to 25mm-25.5mm of the commerical ones I picked up during this), and don't really get the behavior I'm expecting.

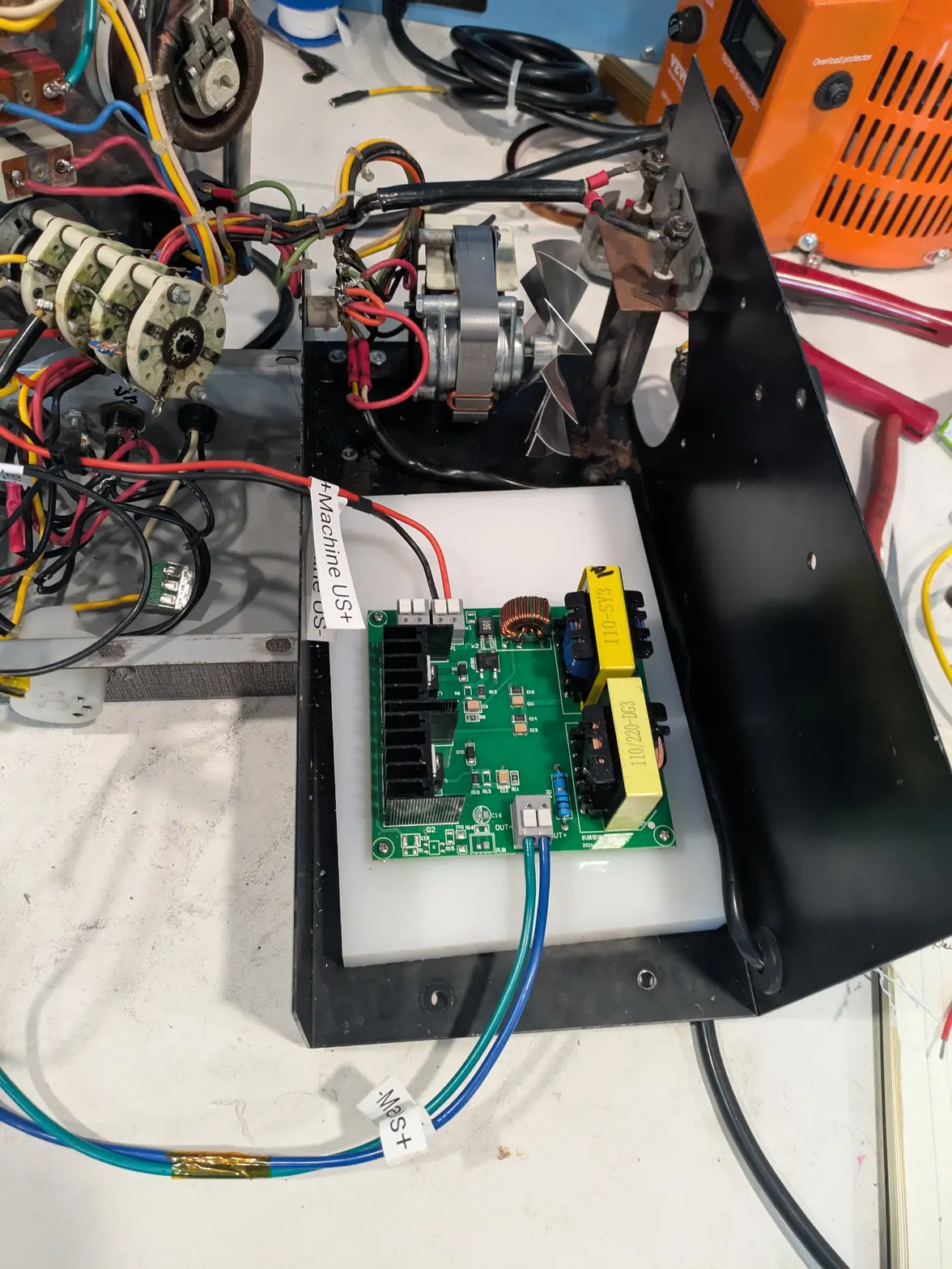

I'll probably have to spend a bunch more time on this. Alternatively, since the size is now 'about right', I might just hook it up to a driver board and see what happens.

I can do this test pretty easily/predictably with the off-the-shelf transducers, they work fine.

However, I'm not really getting anything like that at a reasonable frequency (my measurement was 182khz!), and shortening it didn't seem to change much. So the 'horn'/'can' isn't really working as a resonating horn, and I'm not sure why. I tried shortening it a bunch (down to ~25.75mm horn, compared to 25mm-25.5mm of the commerical ones I picked up during this), and don't really get the behavior I'm expecting.

I'll probably have to spend a bunch more time on this. Alternatively, since the size is now 'about right', I might just hook it up to a driver board and see what happens.