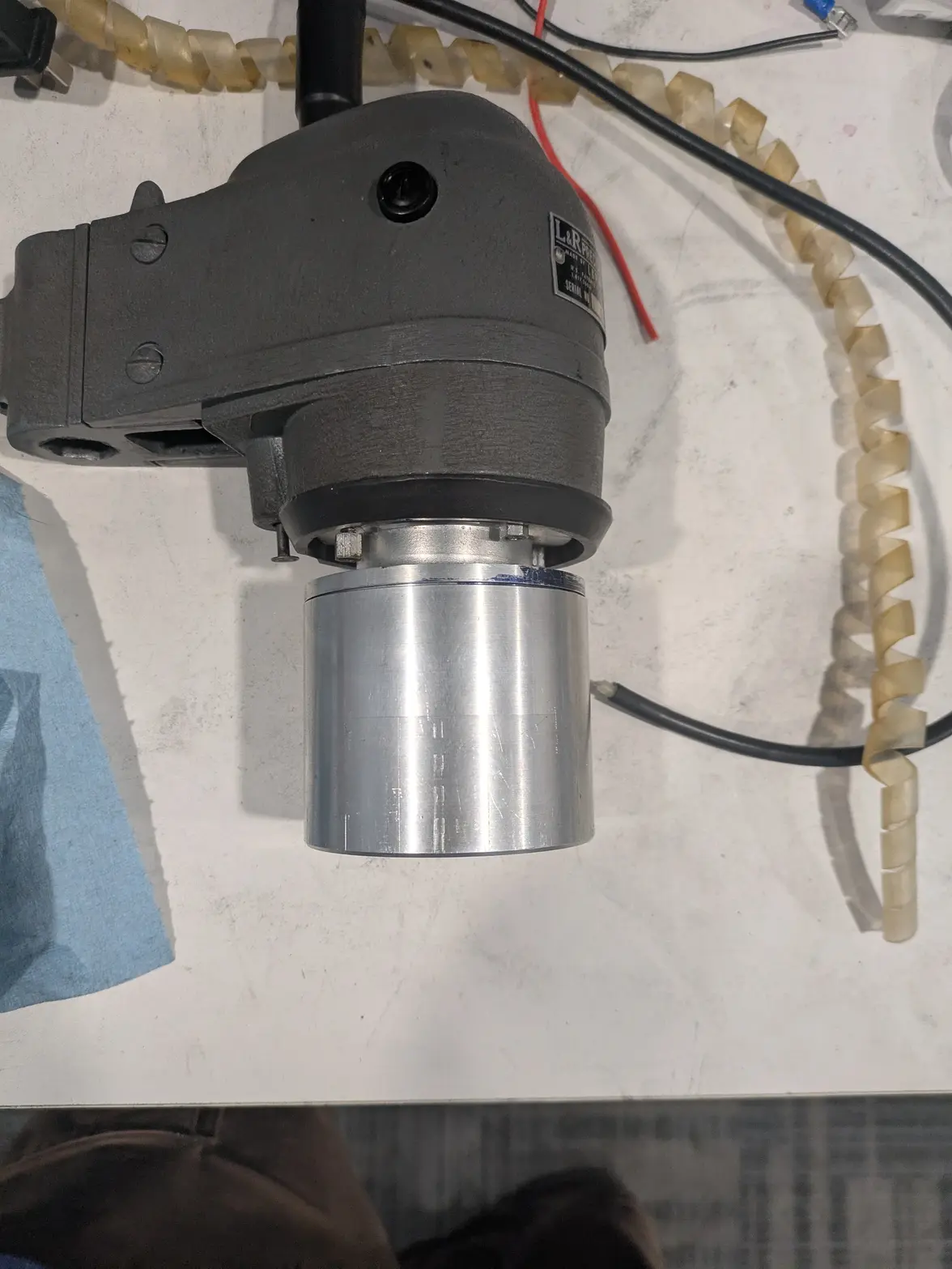

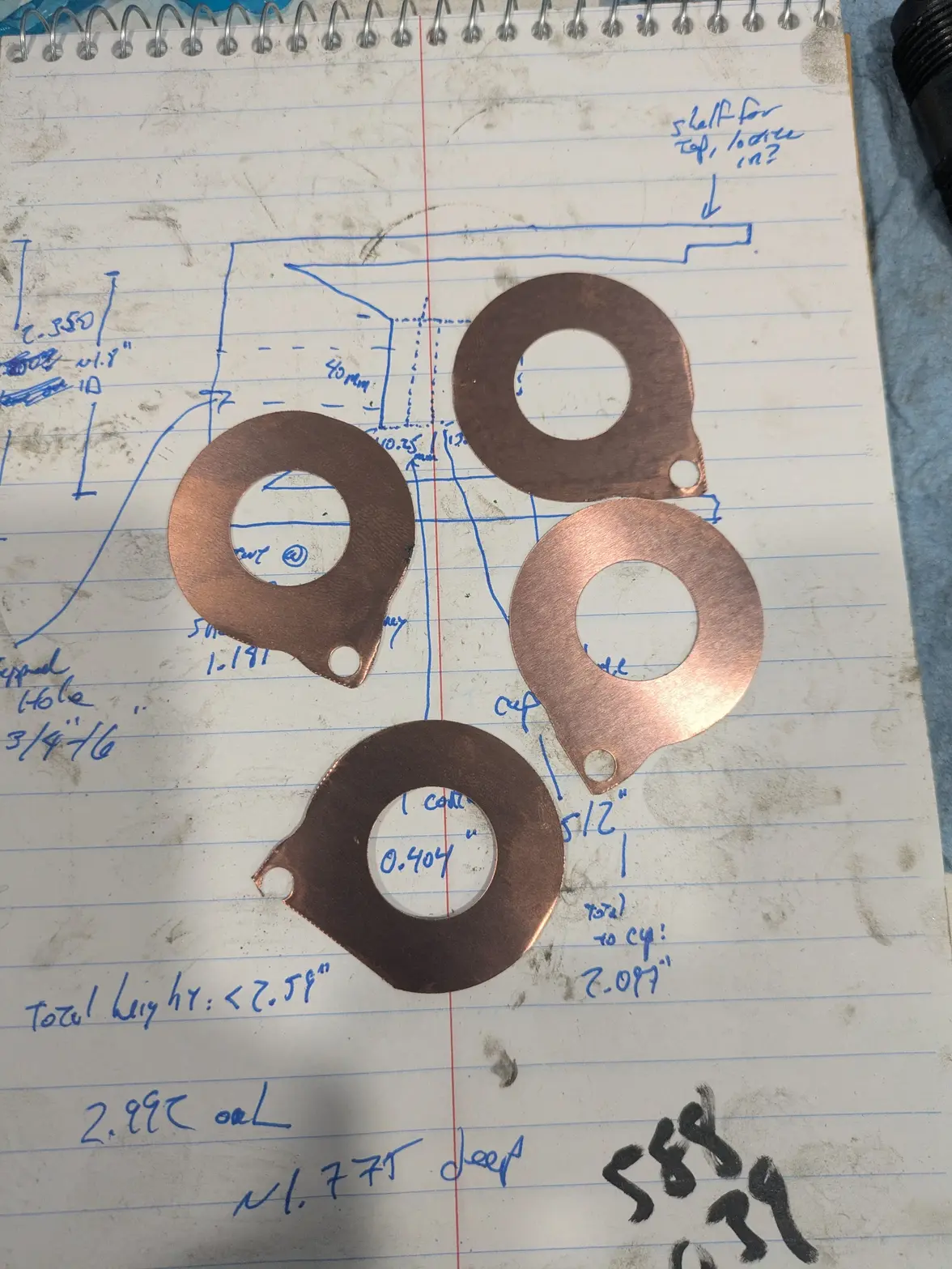

So the first part I started on, and kind of the key to this whole device, is a horn that also includes the 'cup' from the machine, and has a hole down the middle for the purposes of letting the motor shaft through it. The motor shaft is 10mm, but the clamping force needs to be quite a bit.

I also have 2 sizes of piezo rings. First are the ones harvested above, which are 38mm OD, 15mm ID. Second are coming in a week or so, and are 40mm OD, 20mm ID. I believe the latter will be more 'powerful' and have the bigger inner circle. Because of this, I want to make sure this horn will work for both.

ONE thing that WILL happen with this, the transducer on this will be smaller than the factory can, since that is 3", and I don't need anything bigger than 2". I started with some 2" aluminum bar stock, and cut to a little more than 3" long.

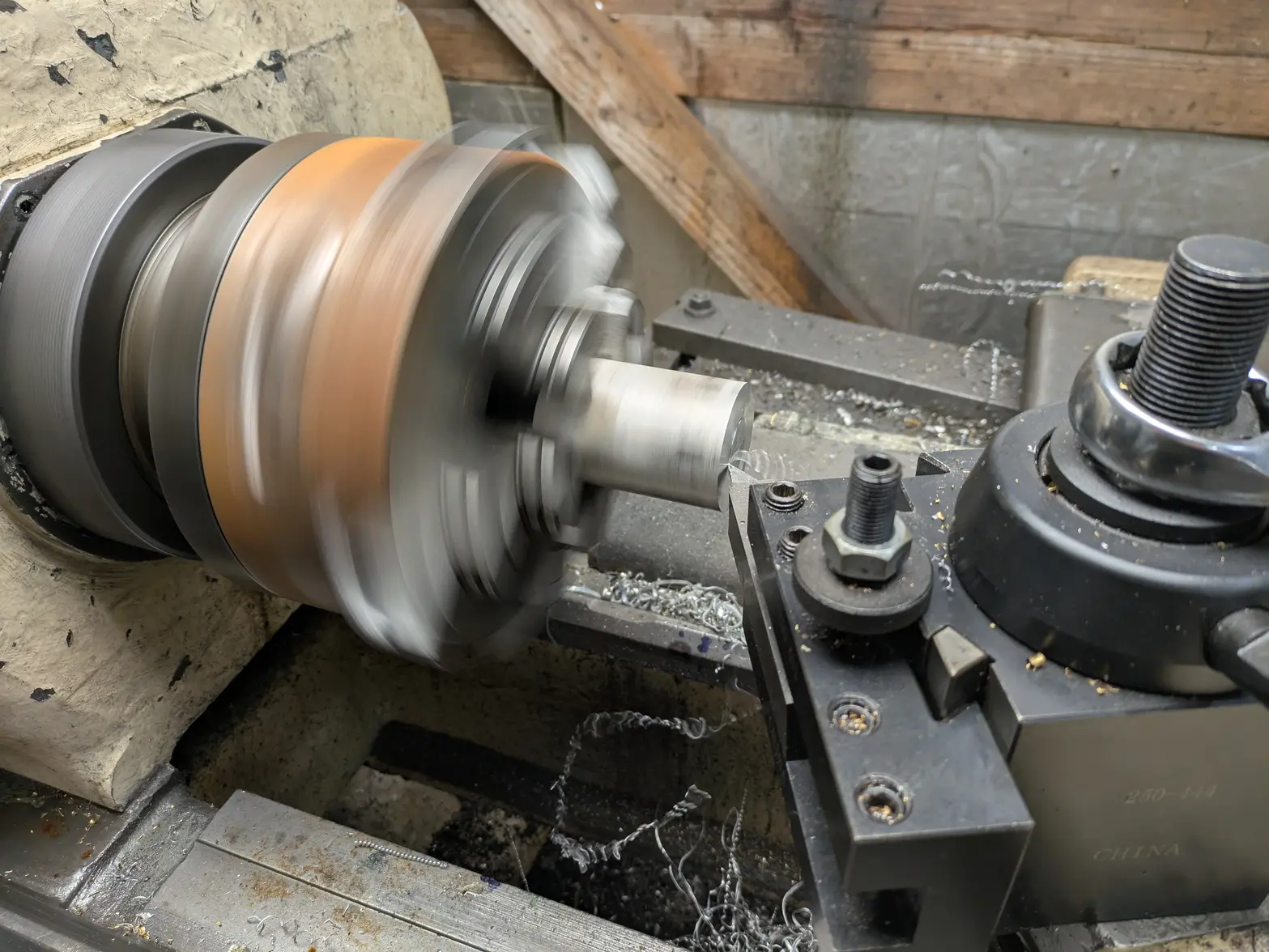

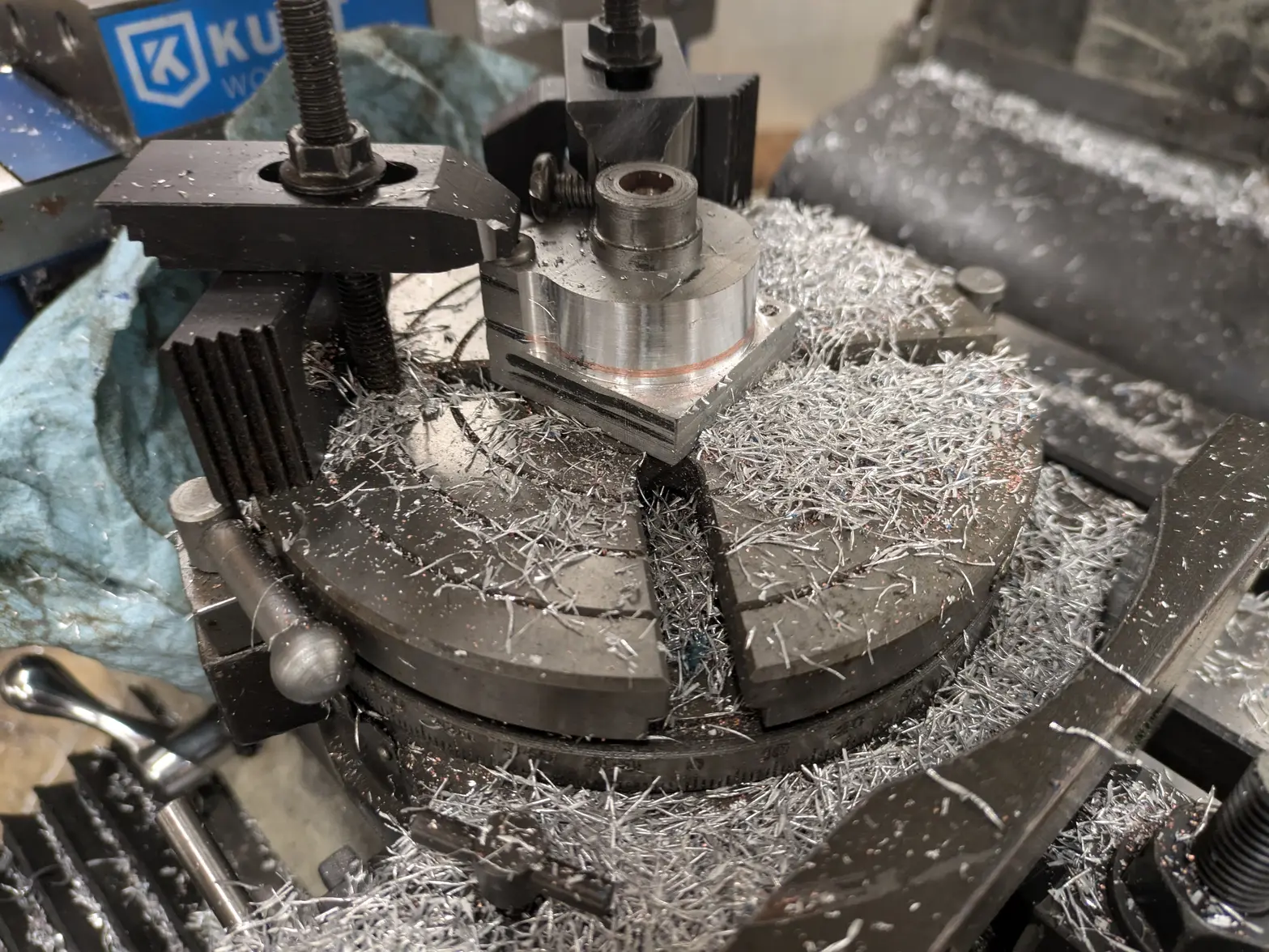

Next I faced and turned 1 side. Facing it makes the 1 end flat/square, and I decided to do a bit of outside turning to make it 'nicer' than factory drawing marks.

After:

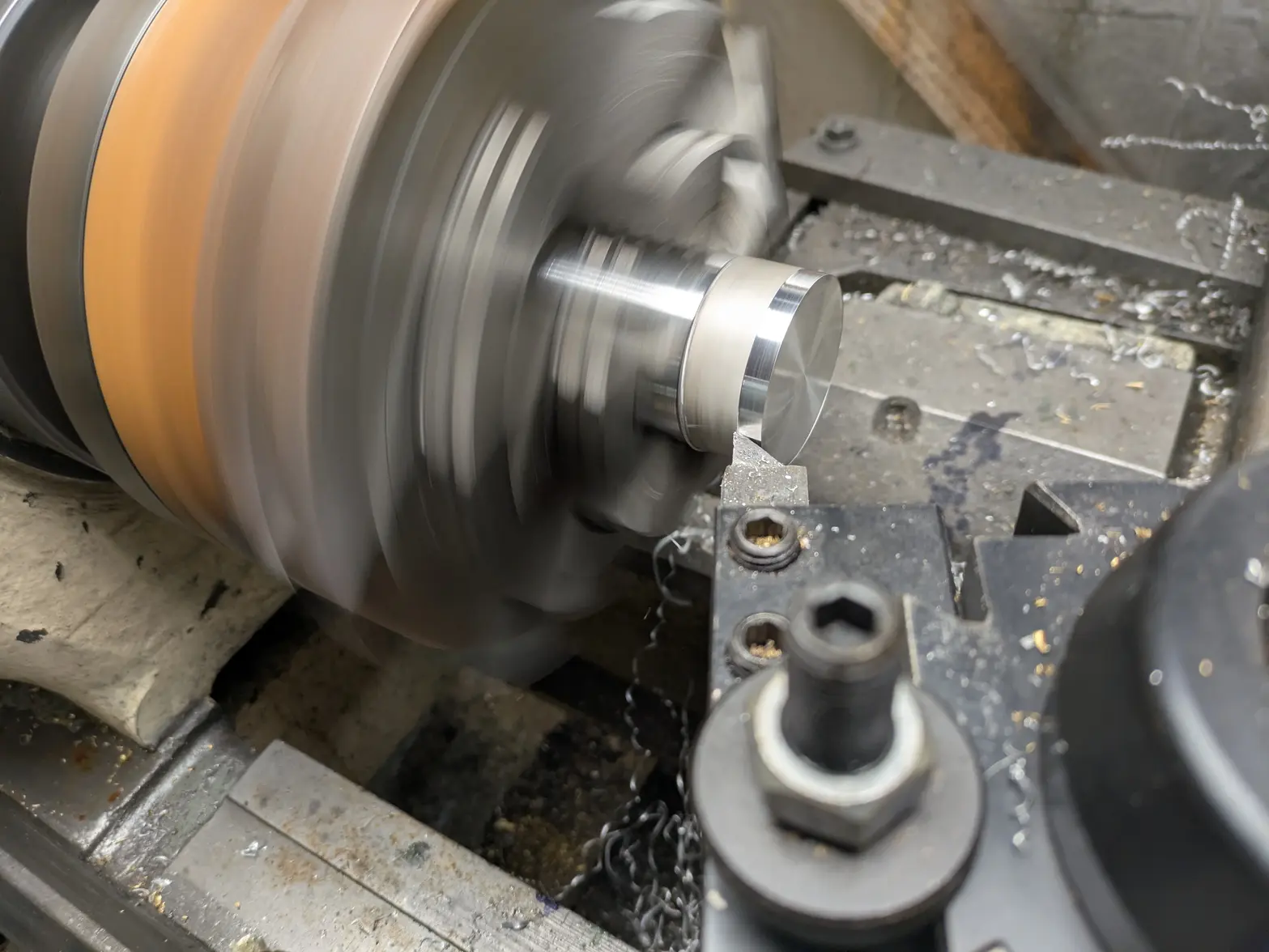

Next I flipped it around in the lathe to do the other side, and faced/turned it. A 'better' machinist would have spent the time to dial it in, as the two won't end up being consentric, but I don't think it matters as I'll do all the work from the other side so that they happen in the same setup. So the only thing that will be 'wrong' is a line between the outside diameter turning from each side:

I missed a photo, but I drilled the center hole to give clearance. I'll eventually be threading this 3/4"-16, which will allow me to make a hollow shaft down the center to be my 'clamping' bolt.

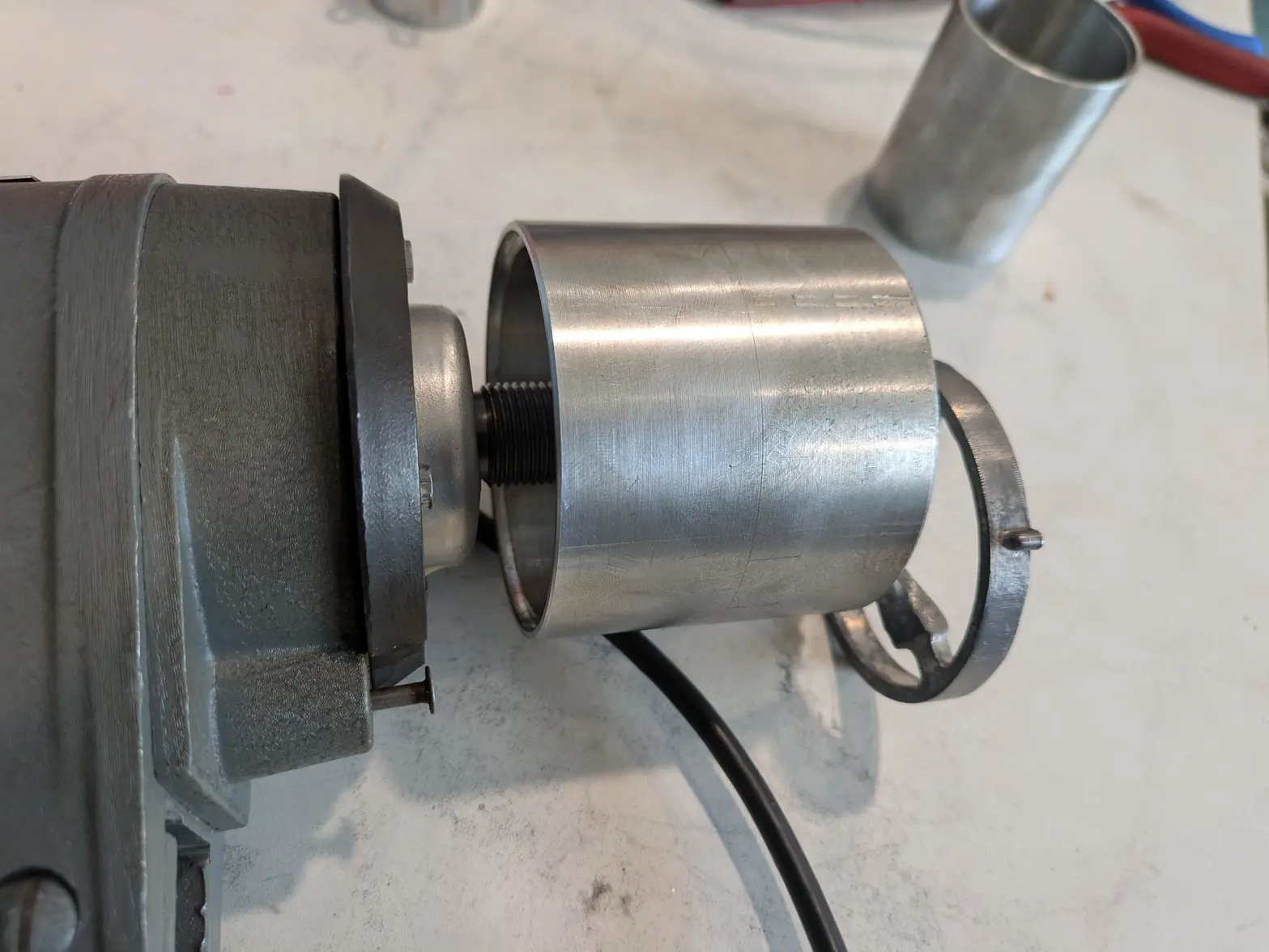

I also started making the clearance for the 'rest' of the transducer parts, plus a nut. I basically just turned the center out.

Here is how it turned out after 1 night.

You can see at the near side that I made some room for the 'cap', which I'll use something to seal off to make this whole unit water tight. Next you can see the clearance, where both piezo rings, wires, and the cap + bolt-head will go.

Finally, you can see the through-hole.

My next steps are: I want to cut a 'bevel' on the inside of it so that it is more 'horn' shaped like the previous one. I want this one to be effectively a 'horn in a cup' design, but as 1 piece.

Also, I have to increase the size of the center hole for 3/4"-16 and tap it (thread it).

There is 2 more parts (the 'hollow shaft + nut') that I'll have to make for this before I can start testing it. I left the bottom of the horn quite long (about 30mm, the factory one is ~25mm). The idea is I can test the resonant frequency on my oscilloscope (let me know if anyone is interested how to do that!), then remove material until I get to exactly 40khz (or at least, close enough I can adjust my driver to do so).

ONCE I have that dialed in, I expect this will be JUST short enough to still fit on the motor shaft and allow the basket holder to still work, plus wiring/etc. I'll still have to make the cap + assemble it in some manner, but those are all details for future Erich

😀

As I said, I won't have the ability to make any more progress for a few days, but if anyone has questions, feel free to ask!