ErichKeane

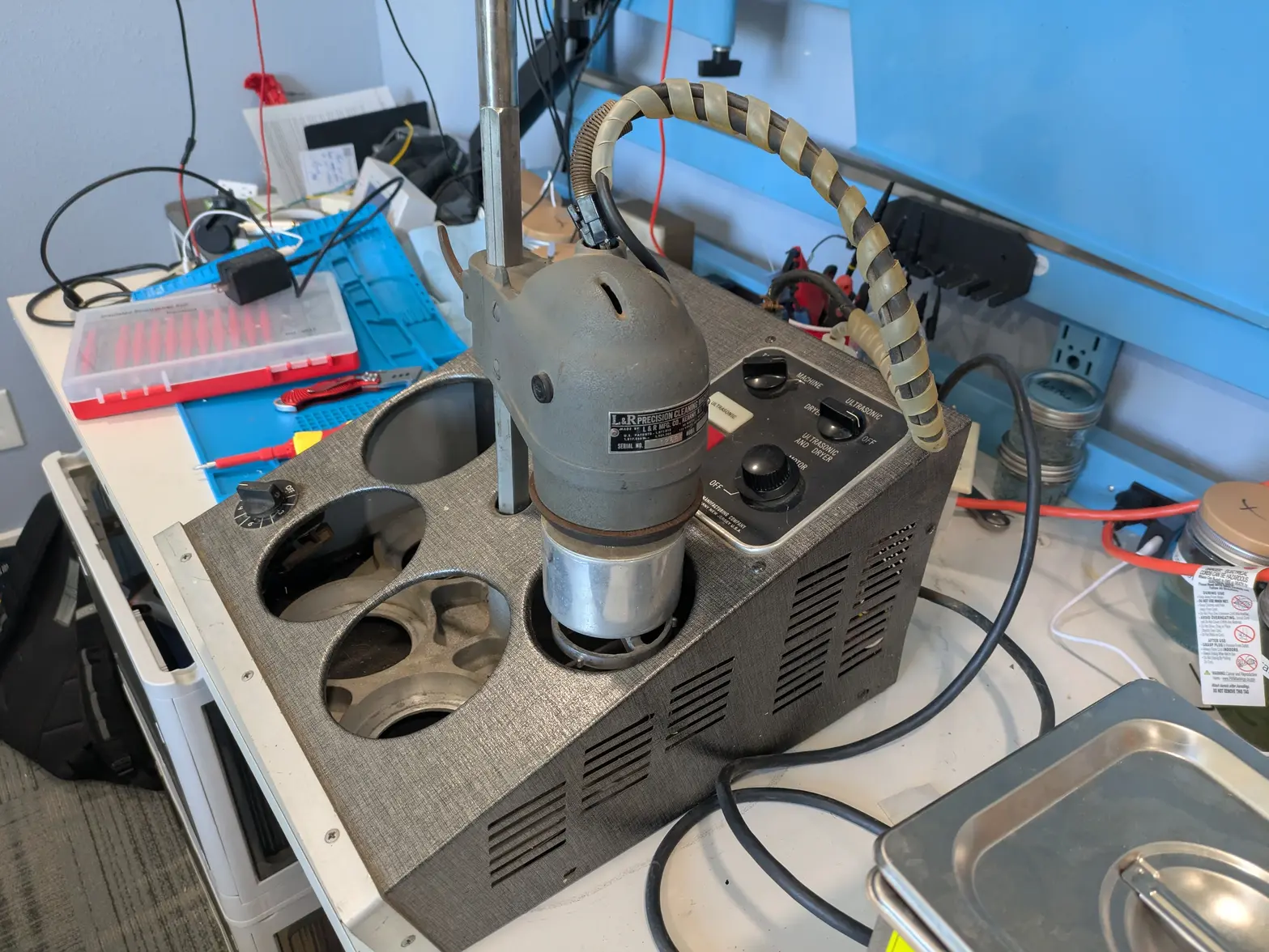

·I've been looking for a good cleaning machine for a while, and found this 'reasonably' priced with a 'make an offer' on Ebay, and it finally showed up today!

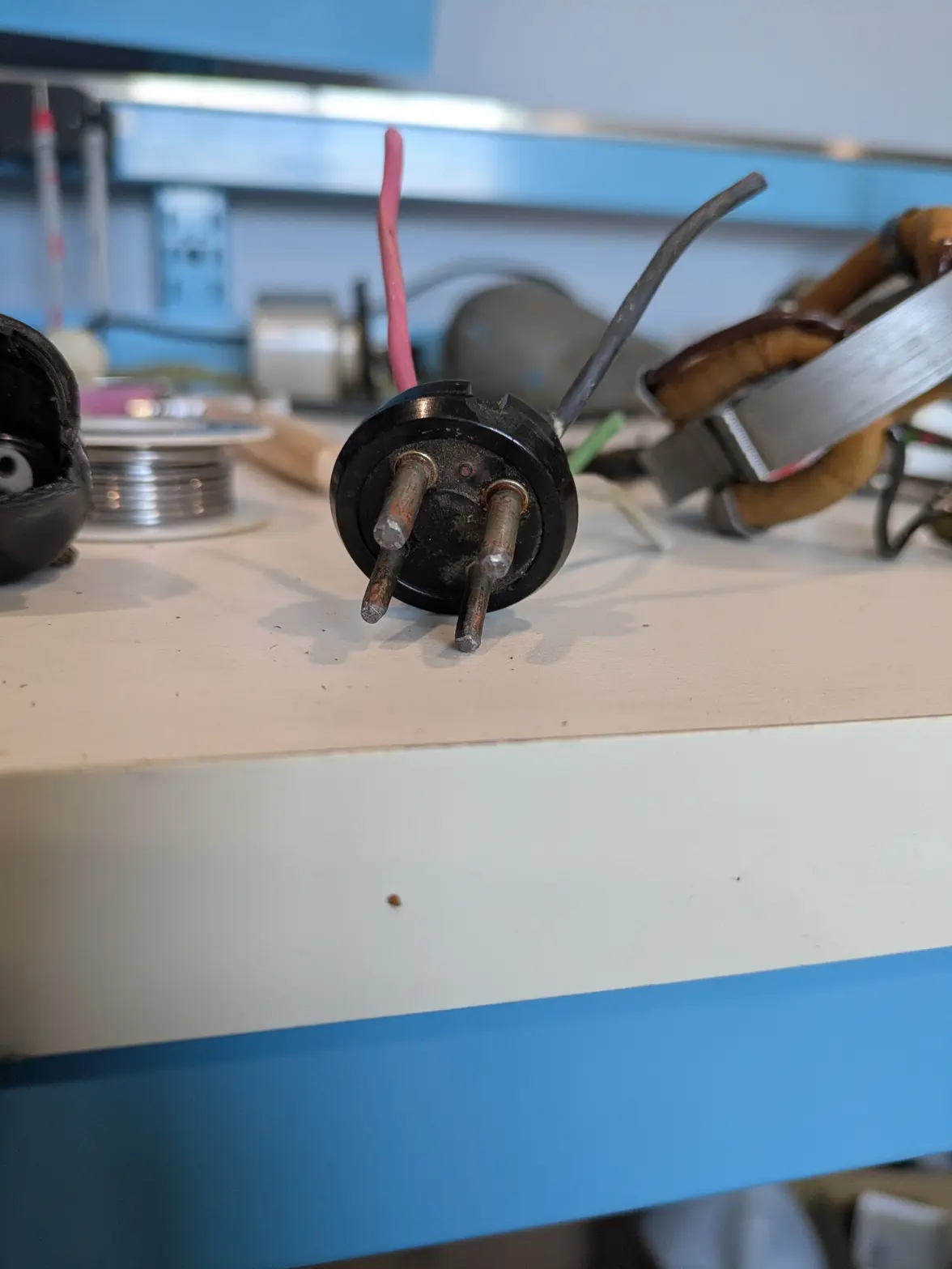

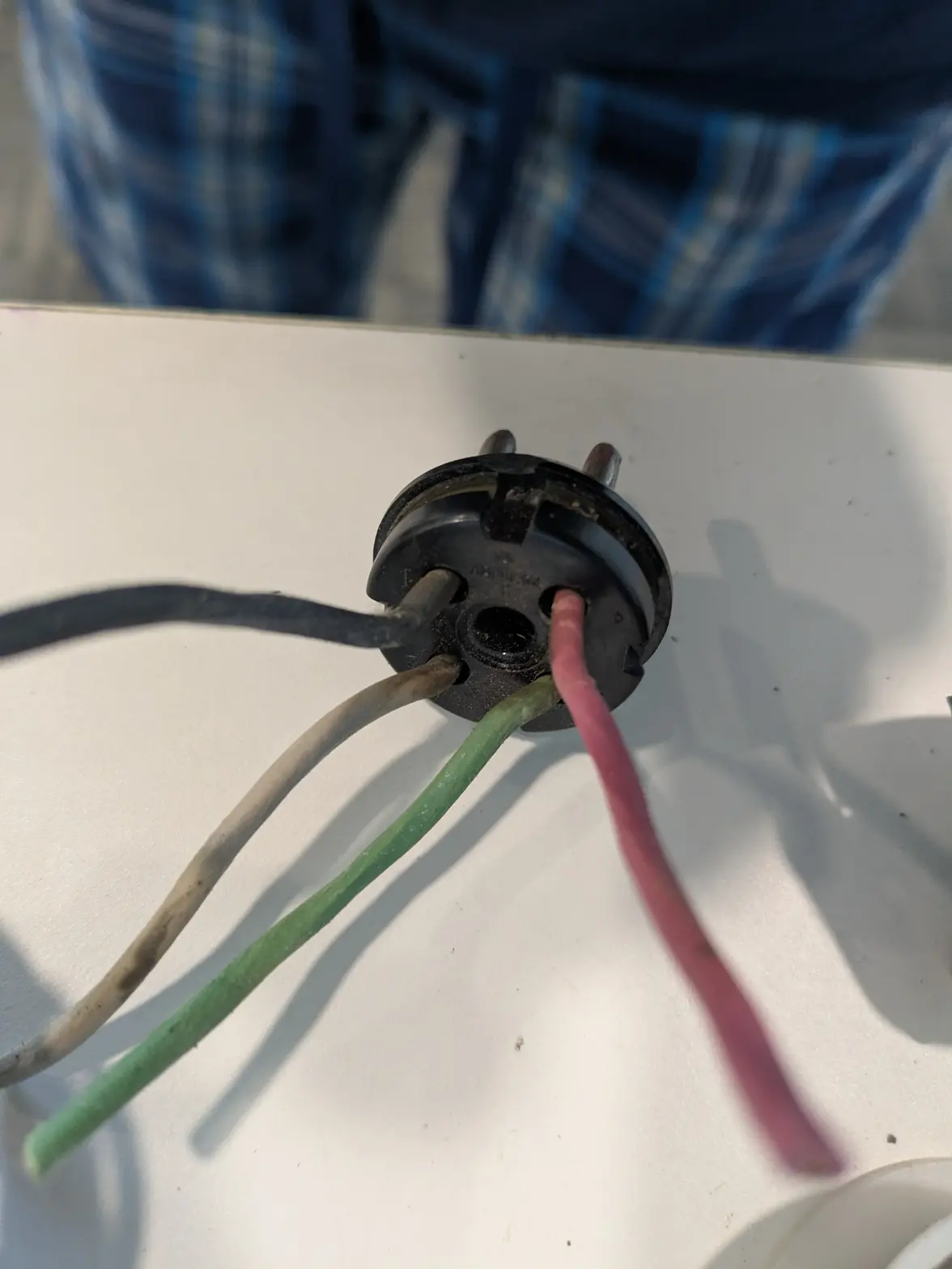

It is a L&R Console machine, sold 'as is', and mentioned that the motor worked, but the ultrasonic did not. I pulled it out and gave it a shot under a dim-bulb tester, and found that the ultrasonic AND heater/fan didn't seem to work, AND the motor only worked when all-the-way on. AND the motor didn't do the auto-reverse even when the button was depressed. Looks like we've got a heck of a project 😀

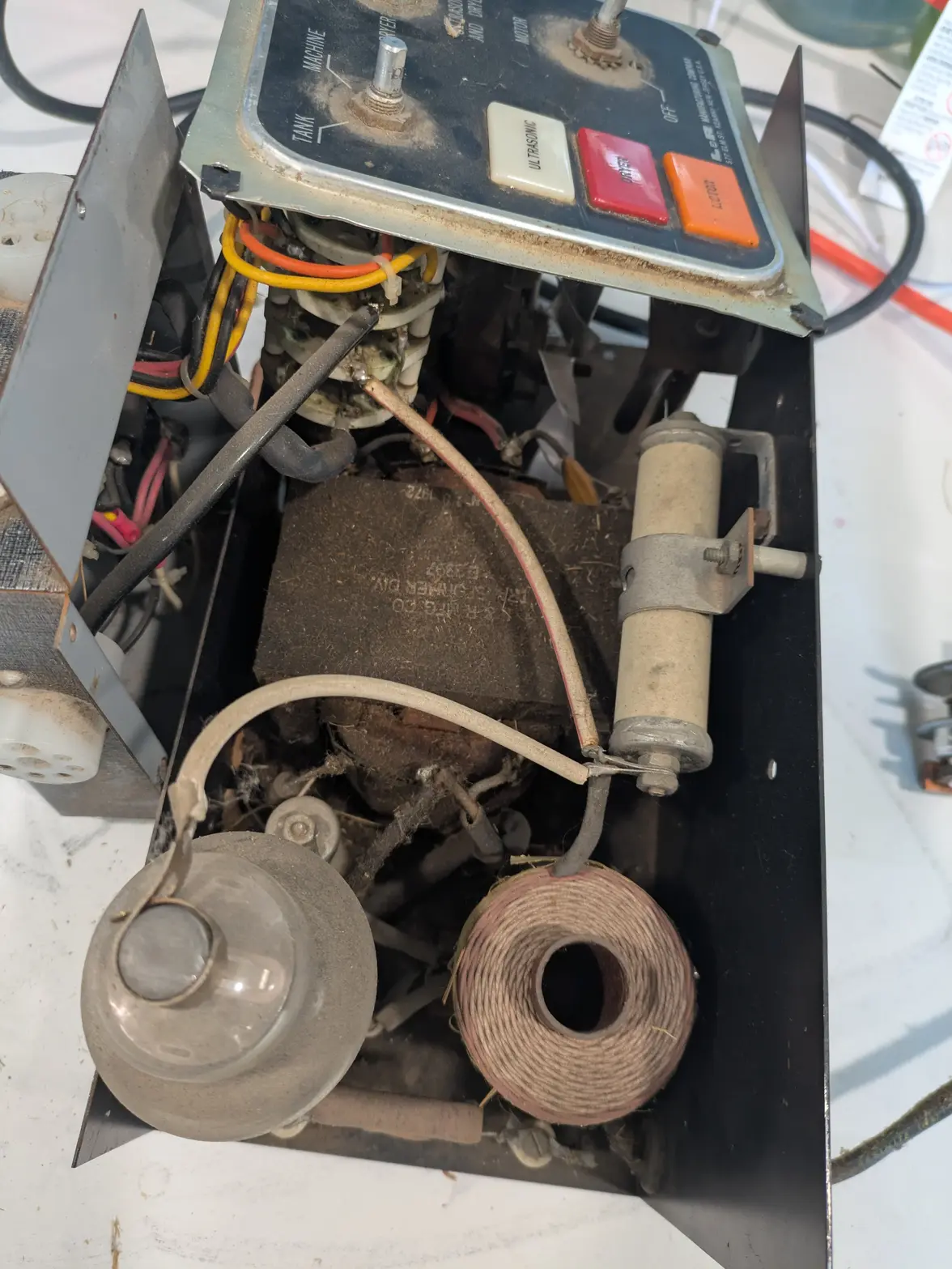

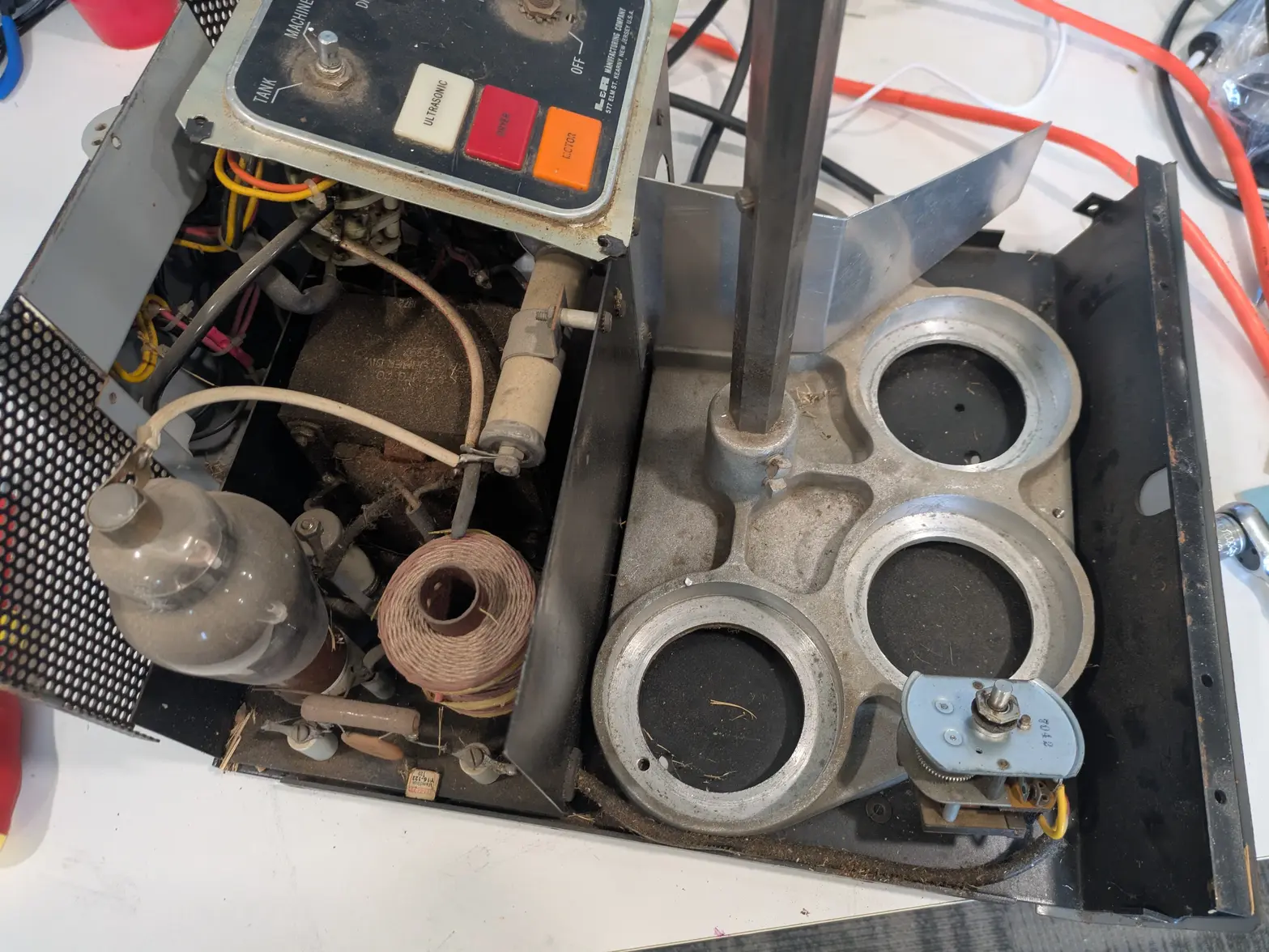

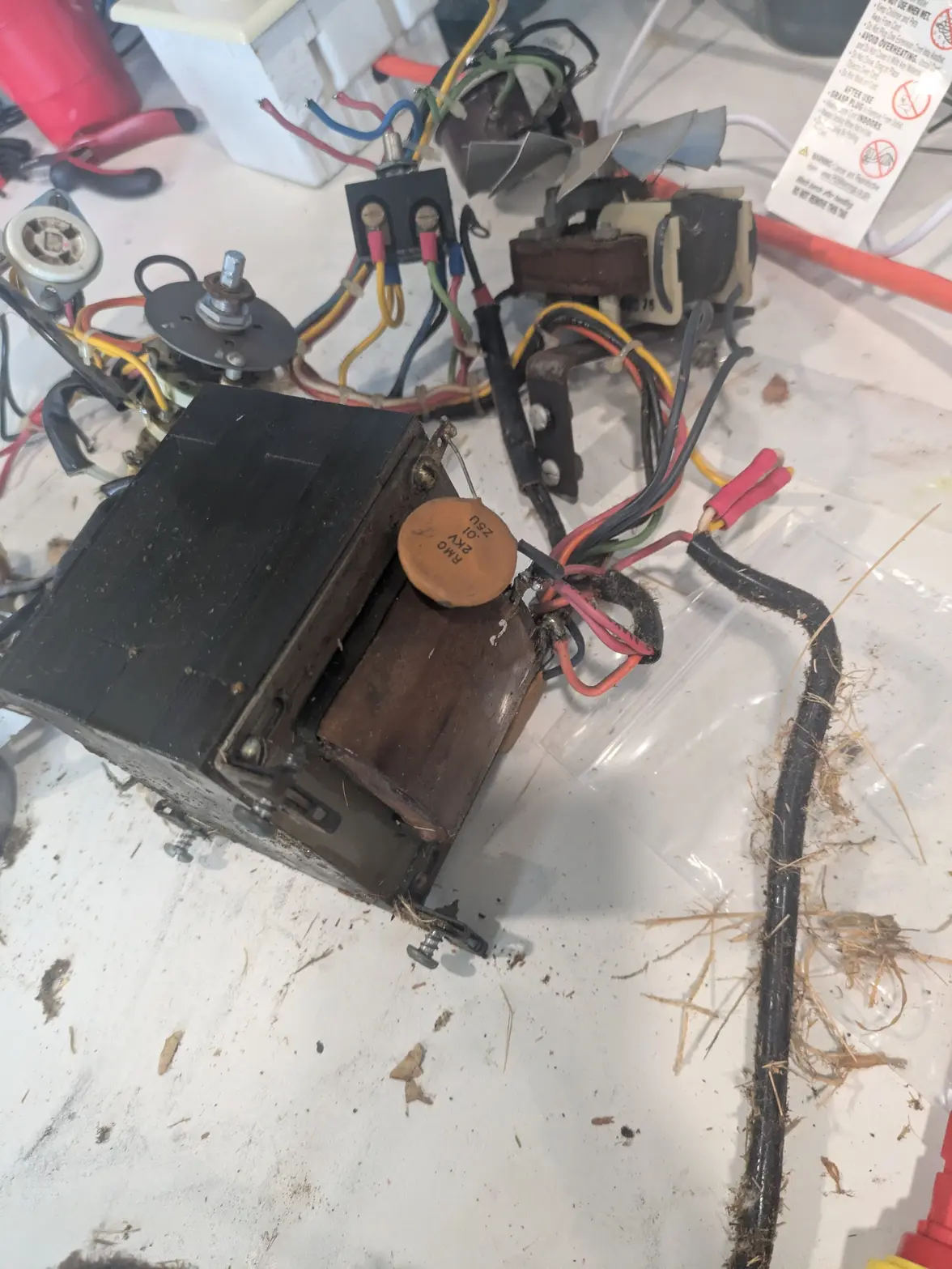

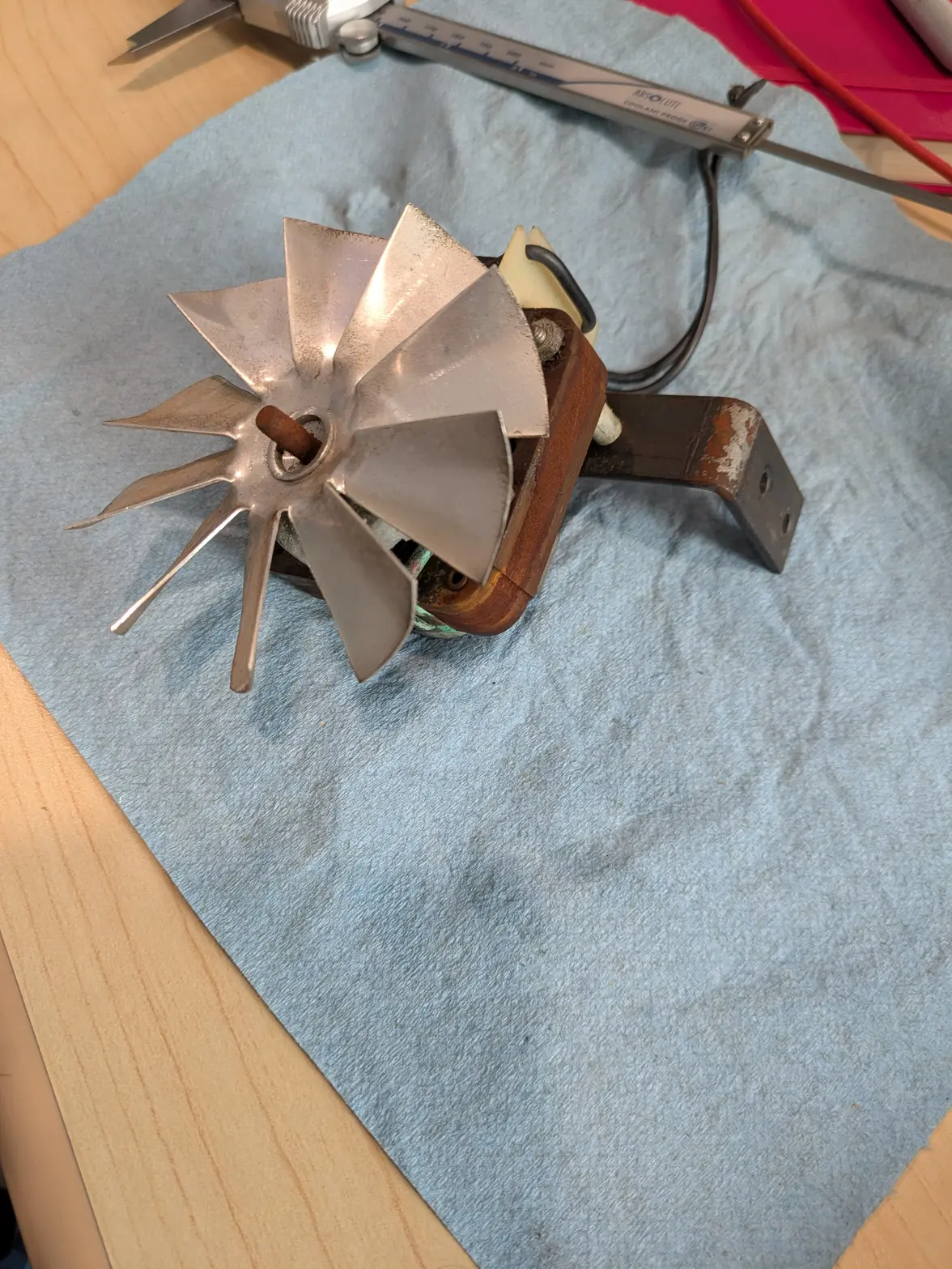

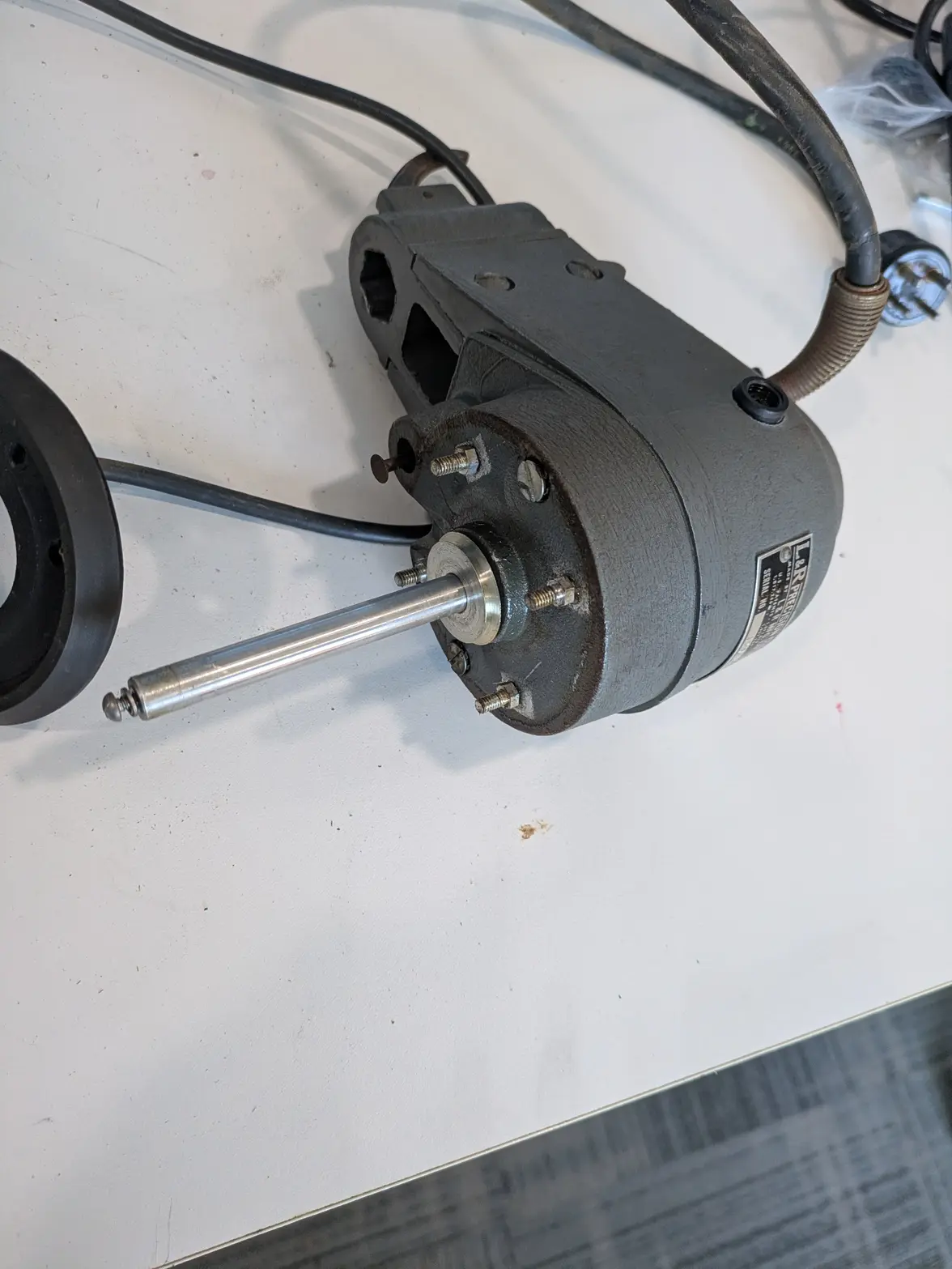

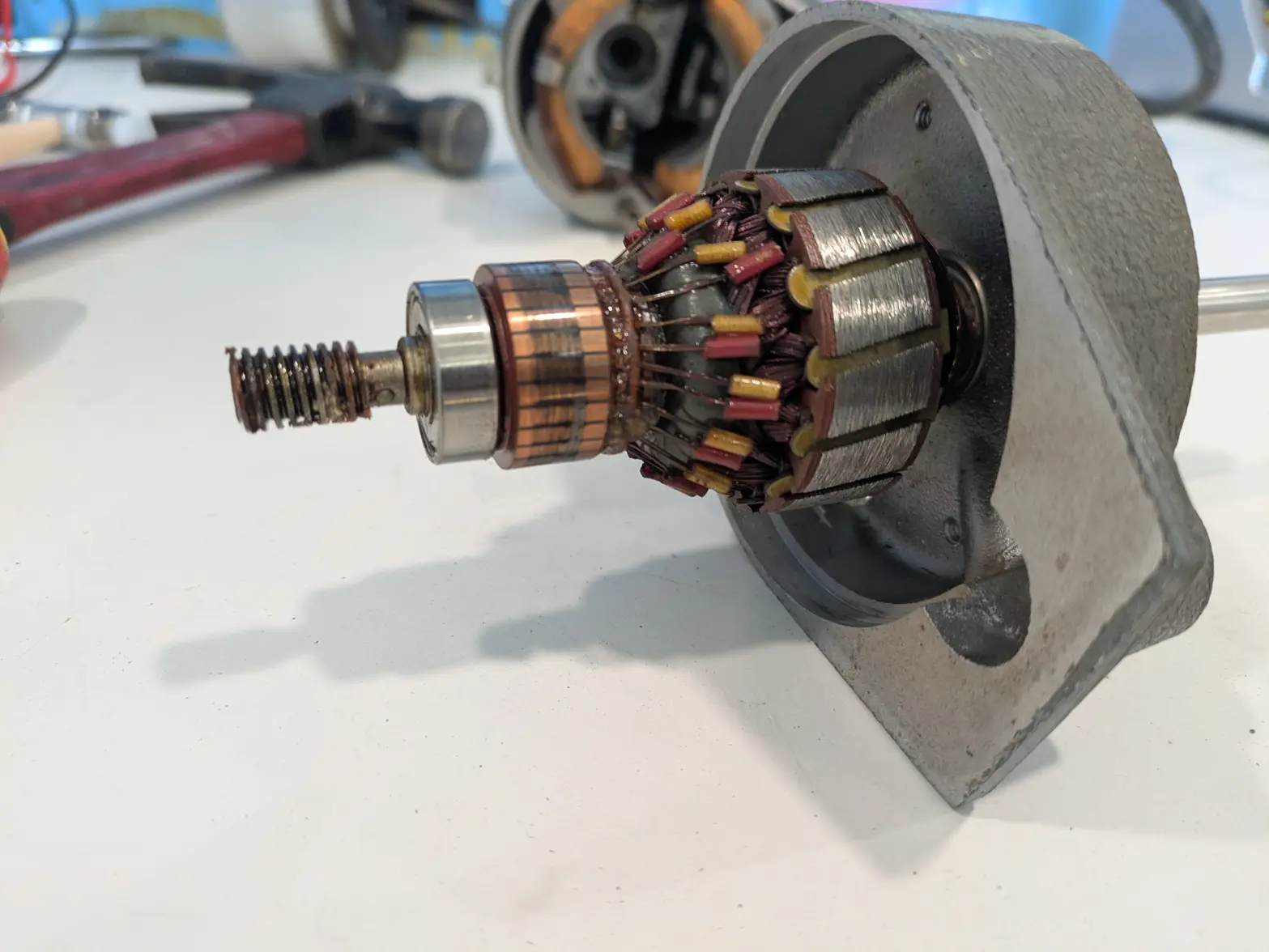

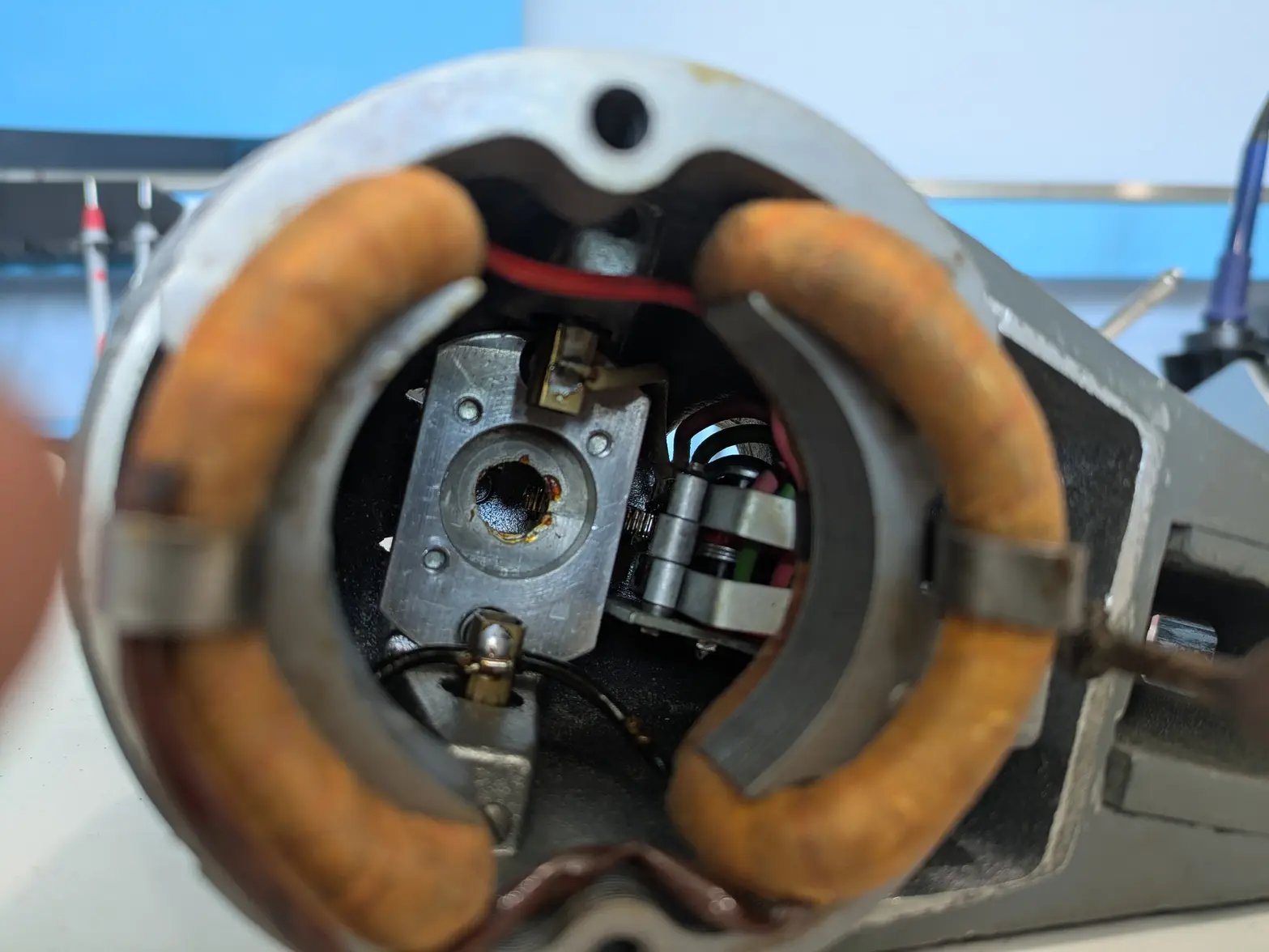

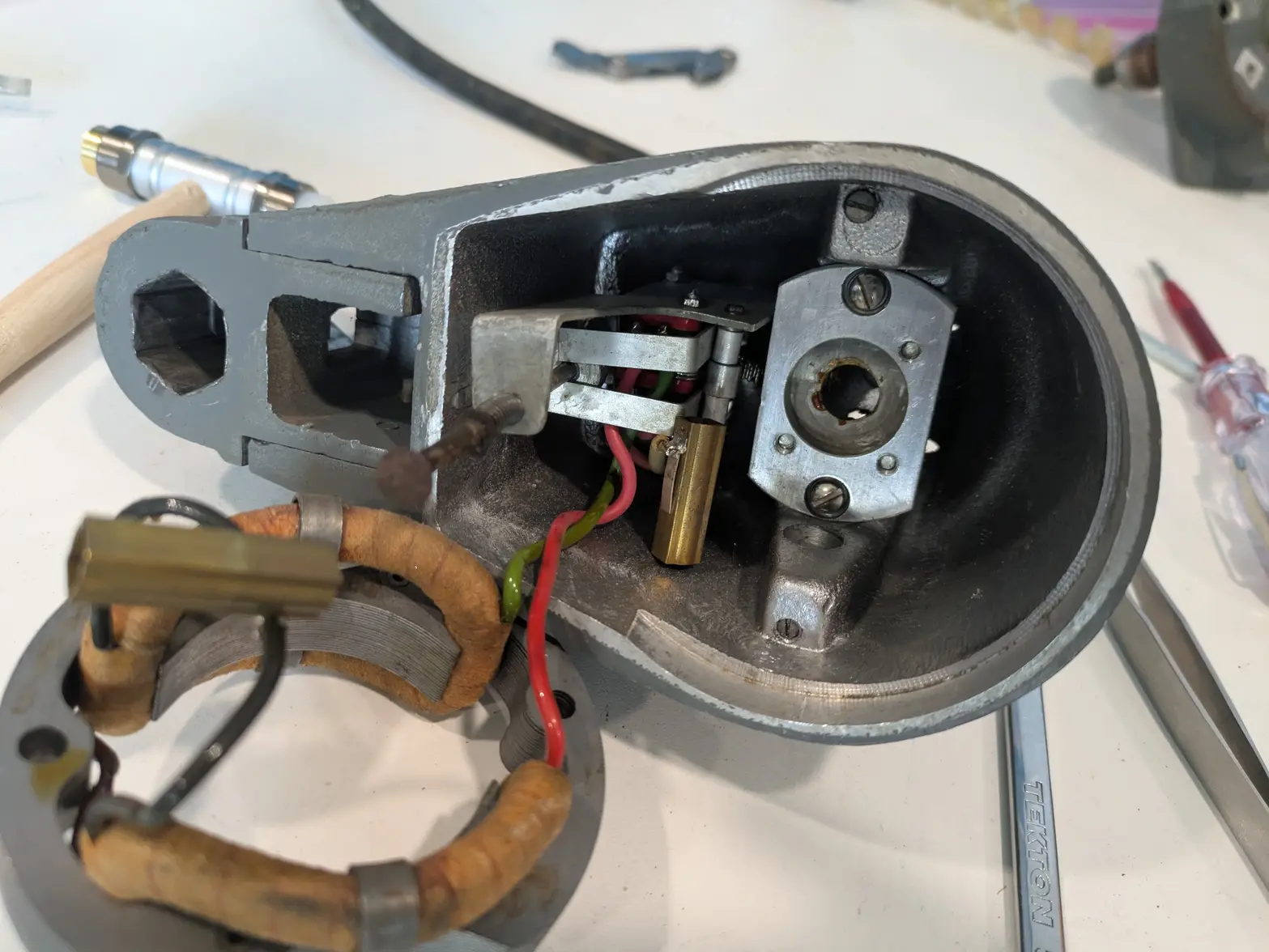

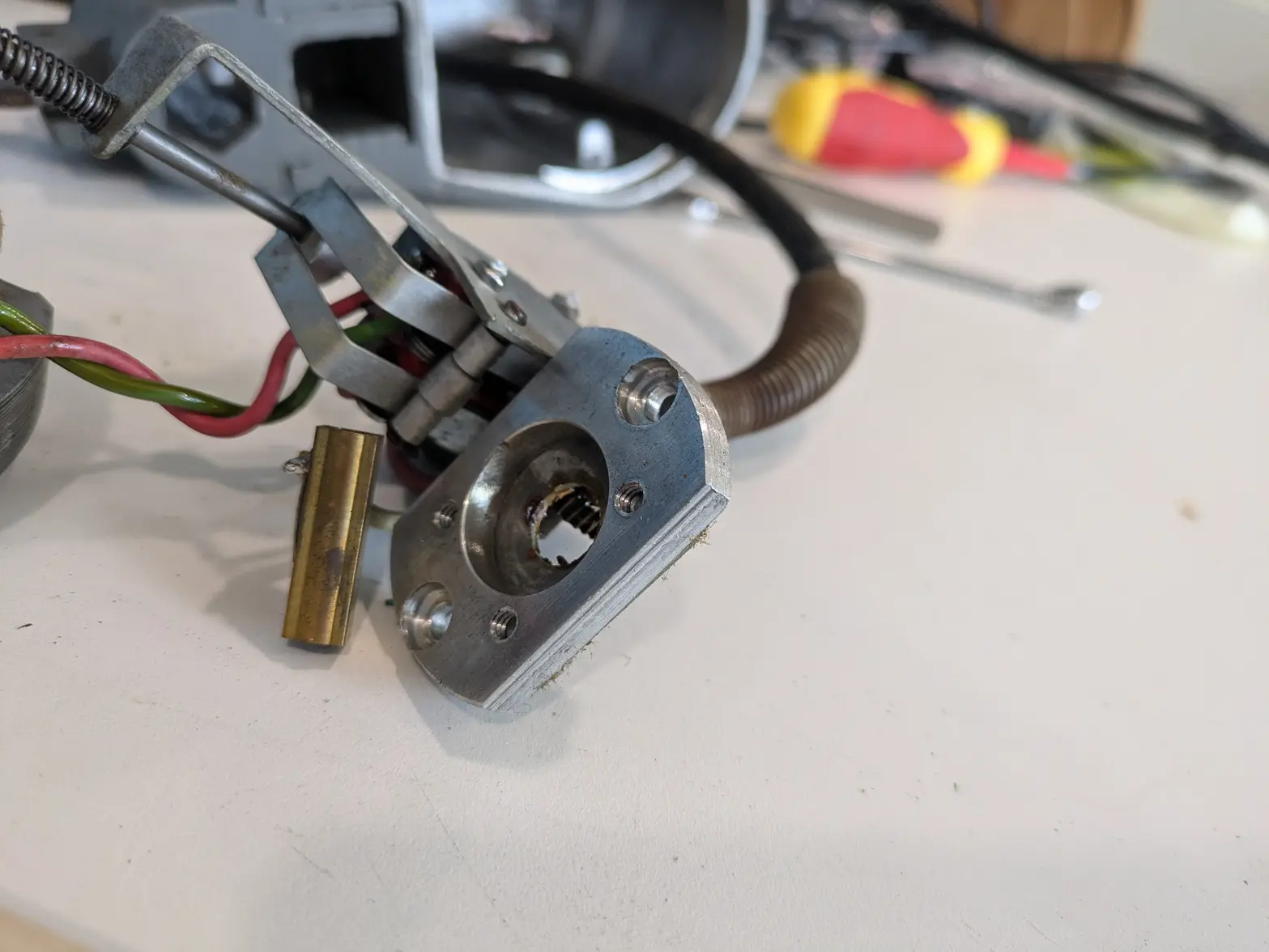

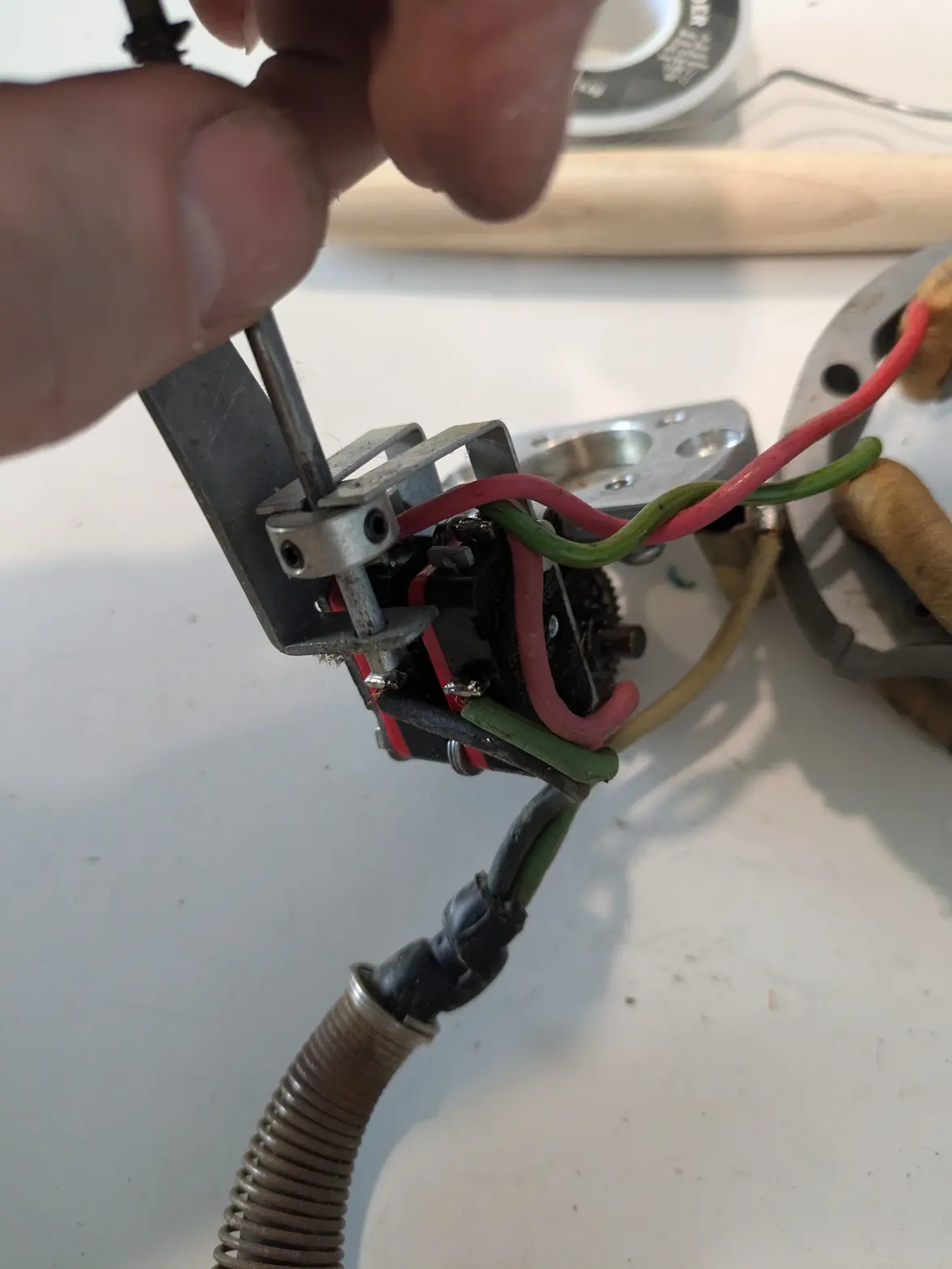

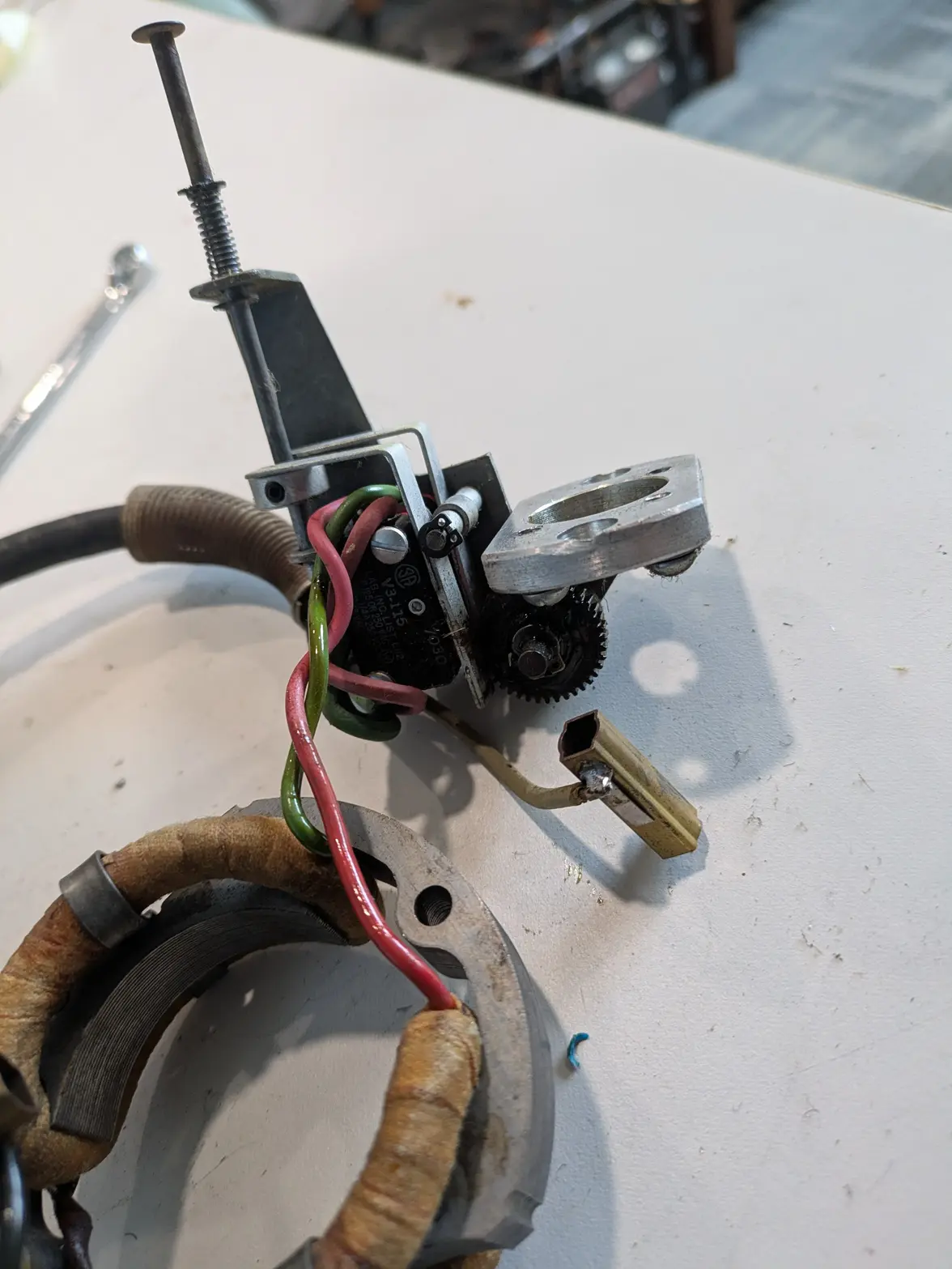

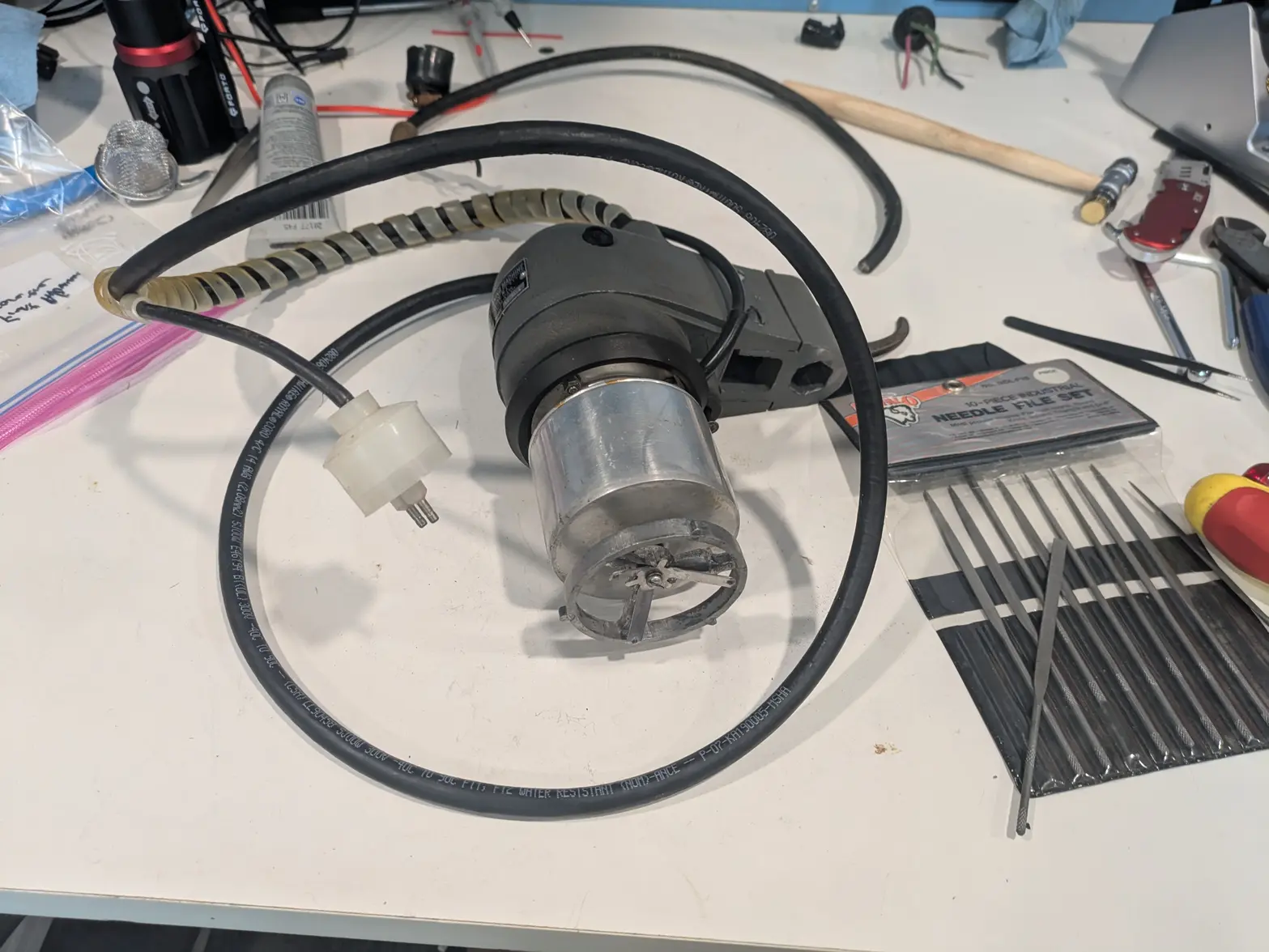

I spent a few hours disassembling it today. I took plenty of pictures, and have to figure out what needs repair. I presume all of the switches dirty/need cleaning in SOME way, and I'm sure there are some other components that need help. My next step is probably going to be to give it a good clean, and try to figure out the wiring diagram. The machine is FILTHY, there is grime and grossness all over the machine, plus some grass, webs, and bugs throughout. I'm guessing this lived in a barn for a while. I ALSO haven't even dug into the head, where the motor and transducer are. The brushes no doubt need some TLC, and the wiring that goes into the head has a busted grommet at least, so I'll have to poke at that as well.

Anyway, a project begins!

It is a L&R Console machine, sold 'as is', and mentioned that the motor worked, but the ultrasonic did not. I pulled it out and gave it a shot under a dim-bulb tester, and found that the ultrasonic AND heater/fan didn't seem to work, AND the motor only worked when all-the-way on. AND the motor didn't do the auto-reverse even when the button was depressed. Looks like we've got a heck of a project 😀

I spent a few hours disassembling it today. I took plenty of pictures, and have to figure out what needs repair. I presume all of the switches dirty/need cleaning in SOME way, and I'm sure there are some other components that need help. My next step is probably going to be to give it a good clean, and try to figure out the wiring diagram. The machine is FILTHY, there is grime and grossness all over the machine, plus some grass, webs, and bugs throughout. I'm guessing this lived in a barn for a while. I ALSO haven't even dug into the head, where the motor and transducer are. The brushes no doubt need some TLC, and the wiring that goes into the head has a busted grommet at least, so I'll have to poke at that as well.

Anyway, a project begins!