RockBurner

·For those interested. 😀

Way back in the 1950s, my dad was a keen youth with a history of bicycle racing and a career in the RAF, and had taken up club-level motorcycle racing, with some success. While racing at Pries Heath* he came up against a "special" that was a JAP Speedway engine that had been fitted into a Triumph road/race frame and was fast, light and reliable. "Hmmm", he thought to himself, "... that's a good idea, I'd like to build one of those one day."

Fast forward 40 years and he found himself with a successful legal career, a large home and a family that were finally becoming independant, and the idea of the JAP special bubbled up into his thoughts again. He'd already founded a small collection of motorcycles after re-gaining the "bug" when forced to commute into London during the train strikes in the 1980s. He'd passed that bug onto his entire family too.

So - he and a friend started gathering the parts, having decided, over long evenings in the family bar** involving lots of whisky, cigars and banter: that the ideal conglomeration of parts would include a Norton Featherbed frame (the special builders' favourite for good reason), the biggest front brake they could find, and while being built up as if it were destined for the track and competion, would actually be road-legal (ish) and somewhat down-tuned to make it easier for aged legs to kickstart!

The bike came together over several years, problems were encountered and solved, parts found, used, replaced, painted, re-painted etc etc.

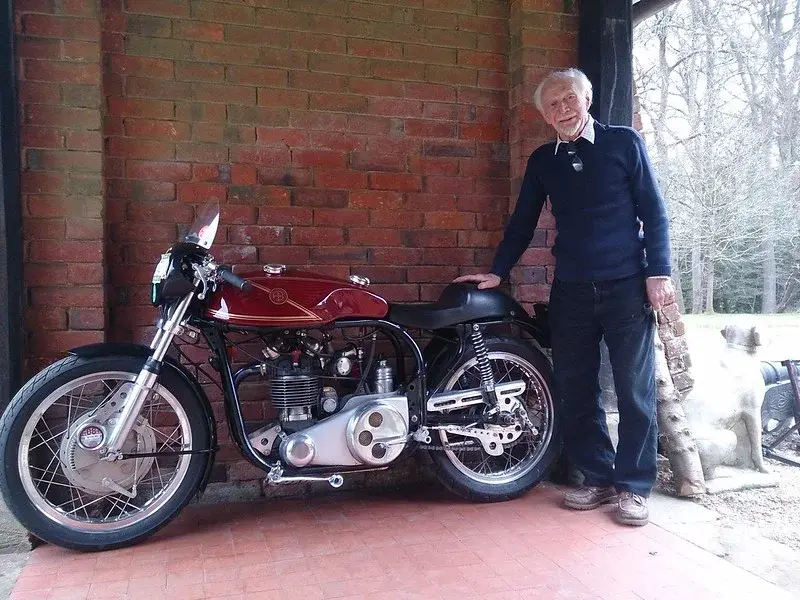

This is the oldest photo I currently have of the bike in it's first "proper" running condition.

At this point it's pretty much all there: although there were obviously developments and changes over the following years.

Here it is again in 2014. New paint and a massive 4-leading shoe Grimeca front brake are the most obvious updates.

Sadly, it was at about this time that my father suffered a stroke and lost the learned ability to balance on 2-wheels. This skill is not an innate thing that we monkeys have inside us, it is a taught/learnt skill that takes time to develop. He also lost some movement abilities on his left side. It didn't stop him wanting to play with his bike so, although the collection was reduced somewhat, he still spend most of his time tinkering with things, and letting others do the riding.

Fast forward again to COVID and sadly my father passed away due to heart issues complicated by contracting COVID while in hospital. 🙁 So, after a time, his pride and joy came out of it's hibernatory storage, and arrived at my new home in 2022.

I've ridden it a few times in the last 3 years, but there was always something wrong with it - and so I've been tinkering and adjusting things ever since.

Last year it died completely while out, luckily only about half-a-mile from home so pushing it back was doable, we're lucky enough that there's a little triangle of roads very close to the house for "testing" purposes (I don't have enough room on the plot for riding it up and down).

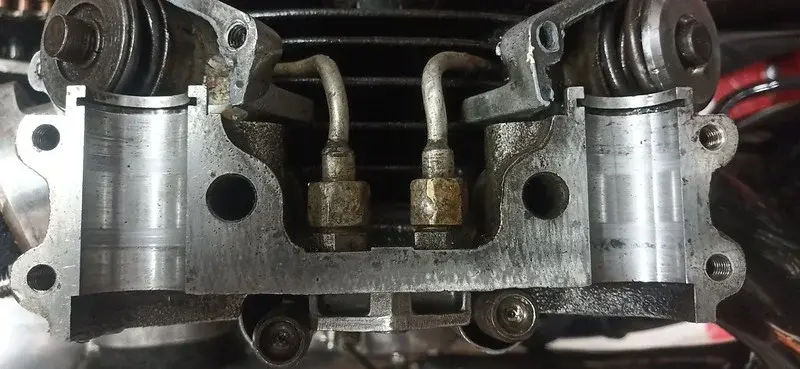

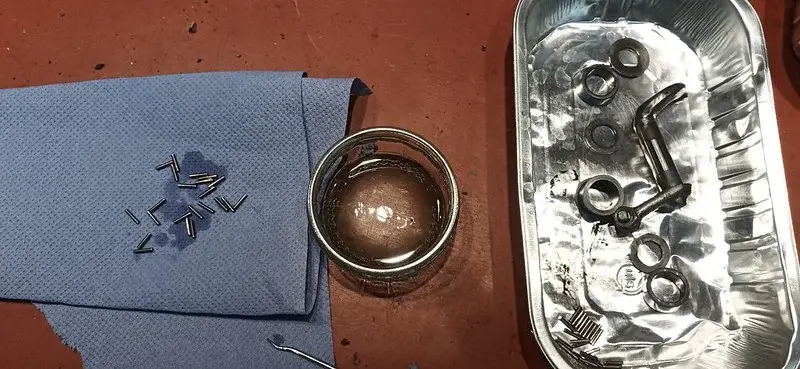

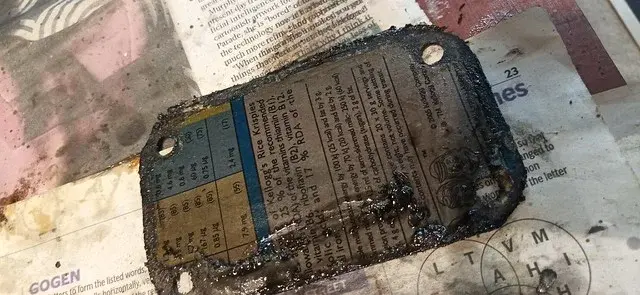

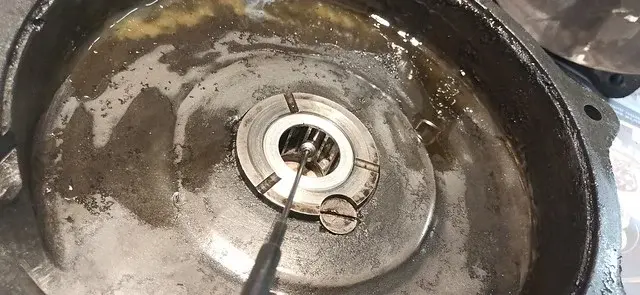

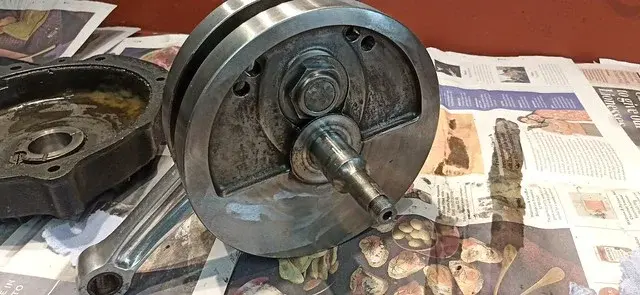

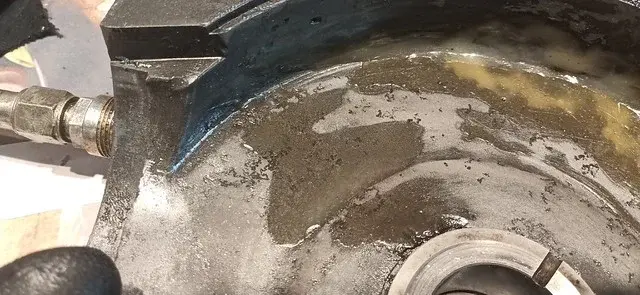

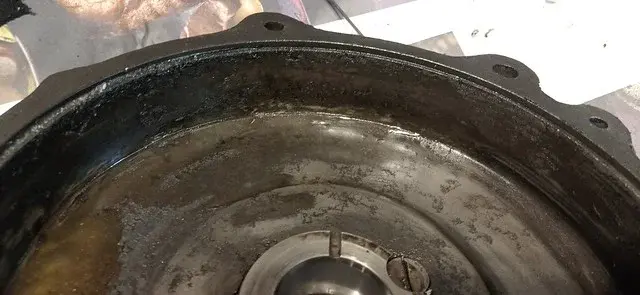

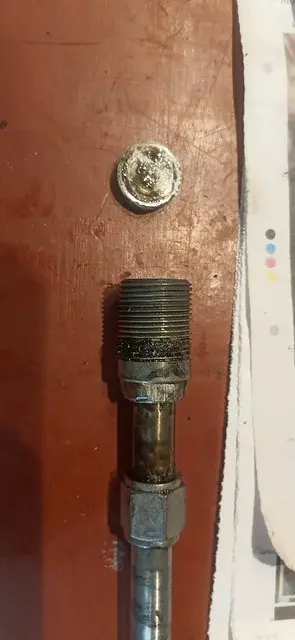

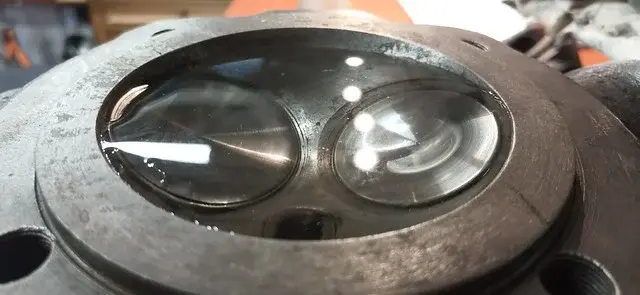

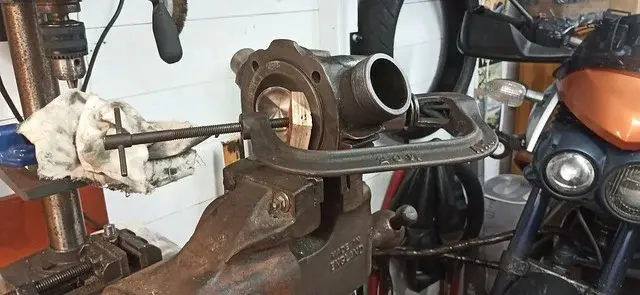

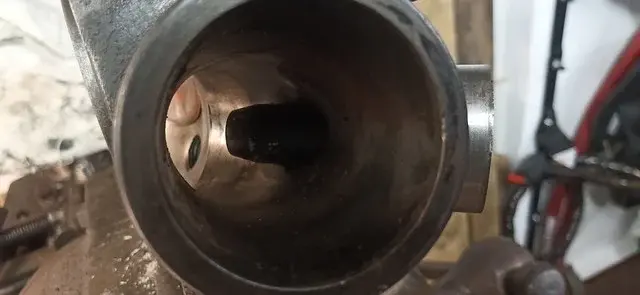

So last winter and this year I've been slowly stripping it down to find out what's wrong... and boy.....

* a track n the North West of England, now long gone, with the distinguishing feature of having a trunk road that went right across the middle, necessitating railway-crossing style barriers that were pulledown across the road during races. 😁 )

** yes - we have a fully functional bar in the house. 😁

Way back in the 1950s, my dad was a keen youth with a history of bicycle racing and a career in the RAF, and had taken up club-level motorcycle racing, with some success. While racing at Pries Heath* he came up against a "special" that was a JAP Speedway engine that had been fitted into a Triumph road/race frame and was fast, light and reliable. "Hmmm", he thought to himself, "... that's a good idea, I'd like to build one of those one day."

Fast forward 40 years and he found himself with a successful legal career, a large home and a family that were finally becoming independant, and the idea of the JAP special bubbled up into his thoughts again. He'd already founded a small collection of motorcycles after re-gaining the "bug" when forced to commute into London during the train strikes in the 1980s. He'd passed that bug onto his entire family too.

So - he and a friend started gathering the parts, having decided, over long evenings in the family bar** involving lots of whisky, cigars and banter: that the ideal conglomeration of parts would include a Norton Featherbed frame (the special builders' favourite for good reason), the biggest front brake they could find, and while being built up as if it were destined for the track and competion, would actually be road-legal (ish) and somewhat down-tuned to make it easier for aged legs to kickstart!

The bike came together over several years, problems were encountered and solved, parts found, used, replaced, painted, re-painted etc etc.

This is the oldest photo I currently have of the bike in it's first "proper" running condition.

At this point it's pretty much all there: although there were obviously developments and changes over the following years.

Here it is again in 2014. New paint and a massive 4-leading shoe Grimeca front brake are the most obvious updates.

Sadly, it was at about this time that my father suffered a stroke and lost the learned ability to balance on 2-wheels. This skill is not an innate thing that we monkeys have inside us, it is a taught/learnt skill that takes time to develop. He also lost some movement abilities on his left side. It didn't stop him wanting to play with his bike so, although the collection was reduced somewhat, he still spend most of his time tinkering with things, and letting others do the riding.

Fast forward again to COVID and sadly my father passed away due to heart issues complicated by contracting COVID while in hospital. 🙁 So, after a time, his pride and joy came out of it's hibernatory storage, and arrived at my new home in 2022.

I've ridden it a few times in the last 3 years, but there was always something wrong with it - and so I've been tinkering and adjusting things ever since.

Last year it died completely while out, luckily only about half-a-mile from home so pushing it back was doable, we're lucky enough that there's a little triangle of roads very close to the house for "testing" purposes (I don't have enough room on the plot for riding it up and down).

So last winter and this year I've been slowly stripping it down to find out what's wrong... and boy.....

* a track n the North West of England, now long gone, with the distinguishing feature of having a trunk road that went right across the middle, necessitating railway-crossing style barriers that were pulledown across the road during races. 😁 )

** yes - we have a fully functional bar in the house. 😁