JwRosenthal

·Greetings all,

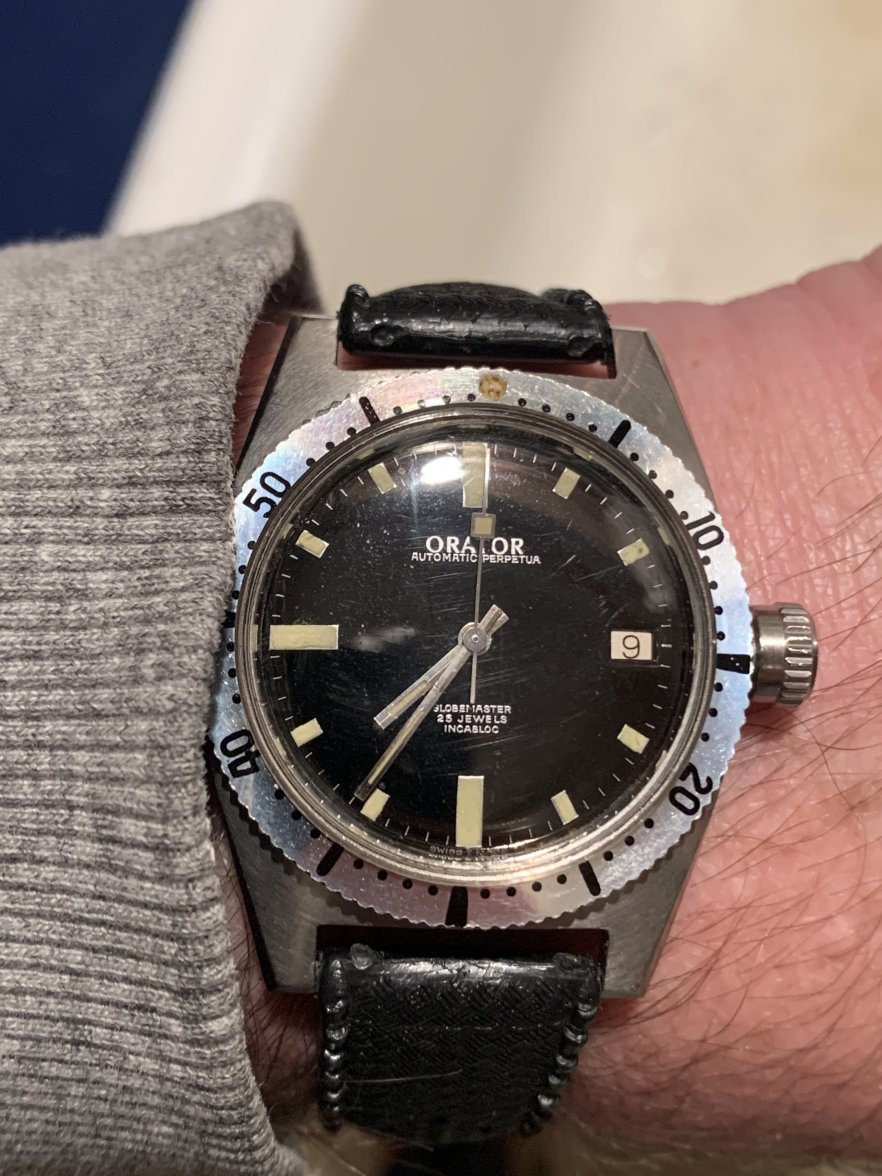

My watch handy friend (not a watchmaker) replaced a crown and tube on a vintage inexpensive automatic diver I had where the screw down crown was stripped. The old tube pressed out fine, new tube installed and when we were cutting the original stem to fit the new crown, we took a little bit too much off 🤦

When you unscrew the crown it pops out into the wind potion fine, pull to set is fine, but when you push it back in, it won’t engage back to the wind position unless you really give it a shove to the point that it hits the threads- and at that it takes a couple times of hard quick pushing for it to engage. Then it screws back down fine.

I remember reading about adding solder or something like that to the end of the stem to add a little length so the crown fits further up on the stem. How many threads are enough to hold the crown properly, is this a viable fix, or do I need to start hunting for a new stem?

Thanks.

My watch handy friend (not a watchmaker) replaced a crown and tube on a vintage inexpensive automatic diver I had where the screw down crown was stripped. The old tube pressed out fine, new tube installed and when we were cutting the original stem to fit the new crown, we took a little bit too much off 🤦

When you unscrew the crown it pops out into the wind potion fine, pull to set is fine, but when you push it back in, it won’t engage back to the wind position unless you really give it a shove to the point that it hits the threads- and at that it takes a couple times of hard quick pushing for it to engage. Then it screws back down fine.

I remember reading about adding solder or something like that to the end of the stem to add a little length so the crown fits further up on the stem. How many threads are enough to hold the crown properly, is this a viable fix, or do I need to start hunting for a new stem?

Thanks.