Hi Archer,

I am a watchmaker, although in recent years I teach at a Swiss watchmaking school with some restoration work on the side.

You are right about modern oils leaving very little residue, and I should probably have used the term "disappearing" instead of "drying" of oils.

My watchmaking experience is somewhat biased towards relatively delicate and thin high-end movements. Like the JLC 920 (or VC, AP or PP versions), movements such as the Patek 240, F. Piguet movements etc. In recent years I have worked on ETA products, and these are very different animals. A lot of these movements can run dry without any clear performance issues.

My experience from yours is a bit different regarding the disappearing of escapement oil. Even with the use of epilames, I have encountered certain high end movements that were running without oil on the escapement after only a few years (and sometimes barely out of warranty). Of course, it is very difficult to determine clear reasons for this, and this is still pretty anecdotal, so I will leave it at that.

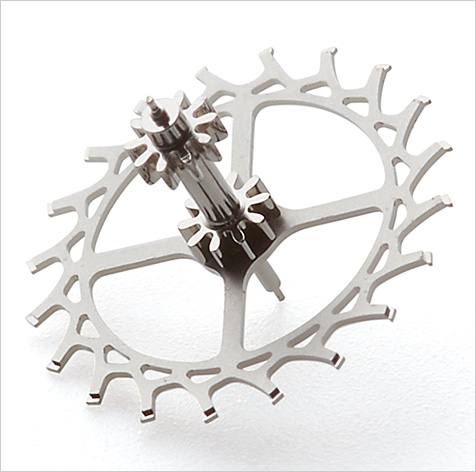

Oil retention on the escapement has been much improved with epilame coatings and improved lubricants such as 9415 grease, however it is still a weak spot relatively speaking. In recent years, many watch companies have invested in silicium escapements as they have the potential of being oil-free. Although to be fair this might be as much a marketing exercise. Although not really a new idea, Seiko has been using escapement wheels with improved teeth design (tiered tips) for oil retention:

The escapement continues to be a component where oiling can be very crucial for achieving an acceptable amplitude and good performance.

As a sidenote, I have always found it somewhat interesting that many so called oil-free escapements such as the Co-Axial, or silicium escapements such as the PP Pulsomax, continue to be oiled in production or during service. I guess the little friction there is, still does damage. Maybe you can shed more light on this, as I have little experience with the Co-Axial escapement myself.

Thanks to the link to your post about your Speedmaster. I think it well highlights how the informed perspective of a watchmaker is quite different from the normal users experience.

Thanks for the discussion!