Archer

··Omega Qualified WatchmakerHi Al

I always use a 4lb lump hammer and centre punch, I'm not a butcher you know😁 Seriously, in my books, punching them out is called bad workmanship as you can damage the hole - makes sense to me with the very hard staff material. I know these need undercutting on a lathe and as I don't have one, this would have to go to someone else. The more I read about staff changes, the more I'm convinced that even if I invest the money in the kit and the time to learn how to use it, it would be hit and miss. So, not the way to go.

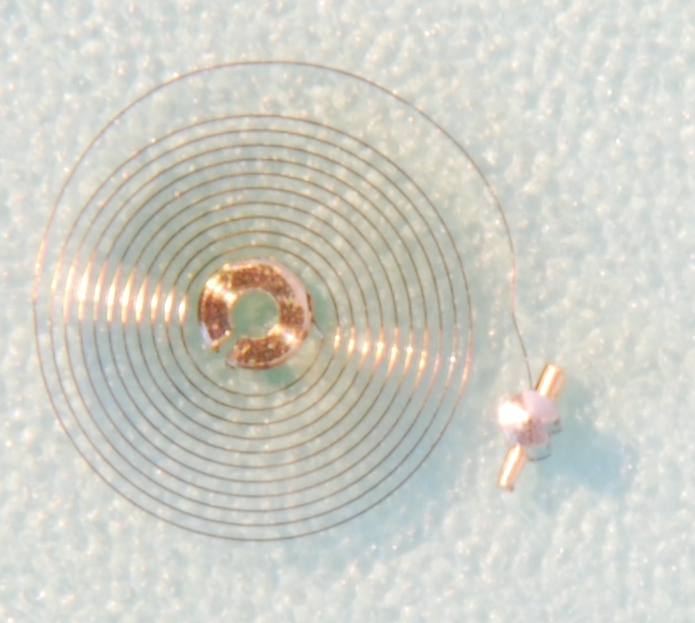

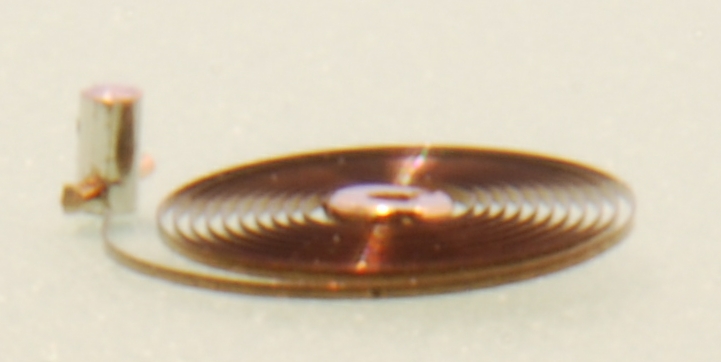

Like I said, back to spring manipulation to see if I can rescue this. Someone has clearly attempted this before as well as messing with the regulation pins so, it might take a while. As you know, I've had some success with hairsprings but really just in plane. It's interesting but frustrating so best to do in small doses.

Cheers, Chris

Well, there are plenty of so called "professionals" that punch them out, so it's more common than you might think.

Doing a staff is a fairly big commitment in tools, so unless you are using the lathe in particular for other things, or have a lot of staffs to do, then probably farming them out for now is the best route.

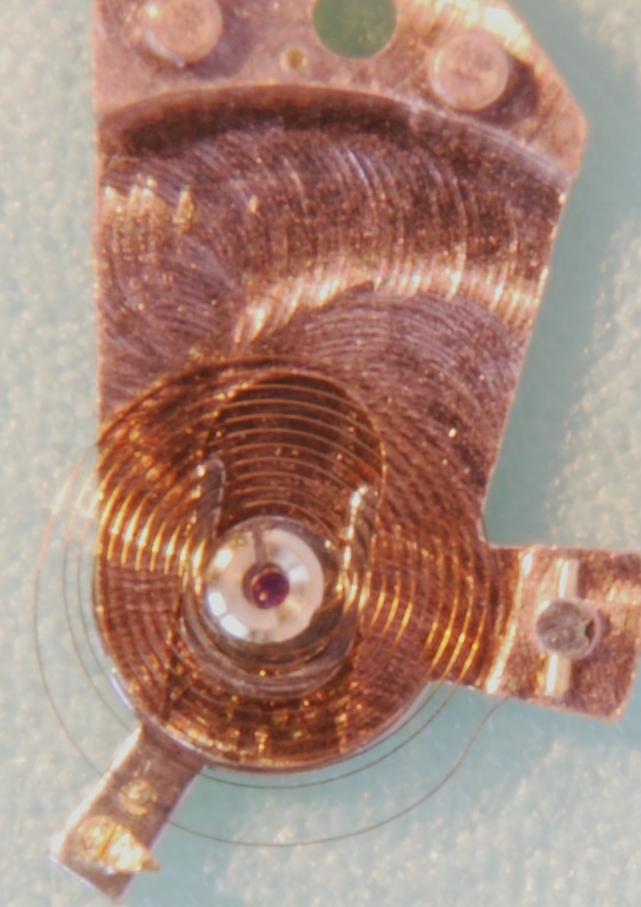

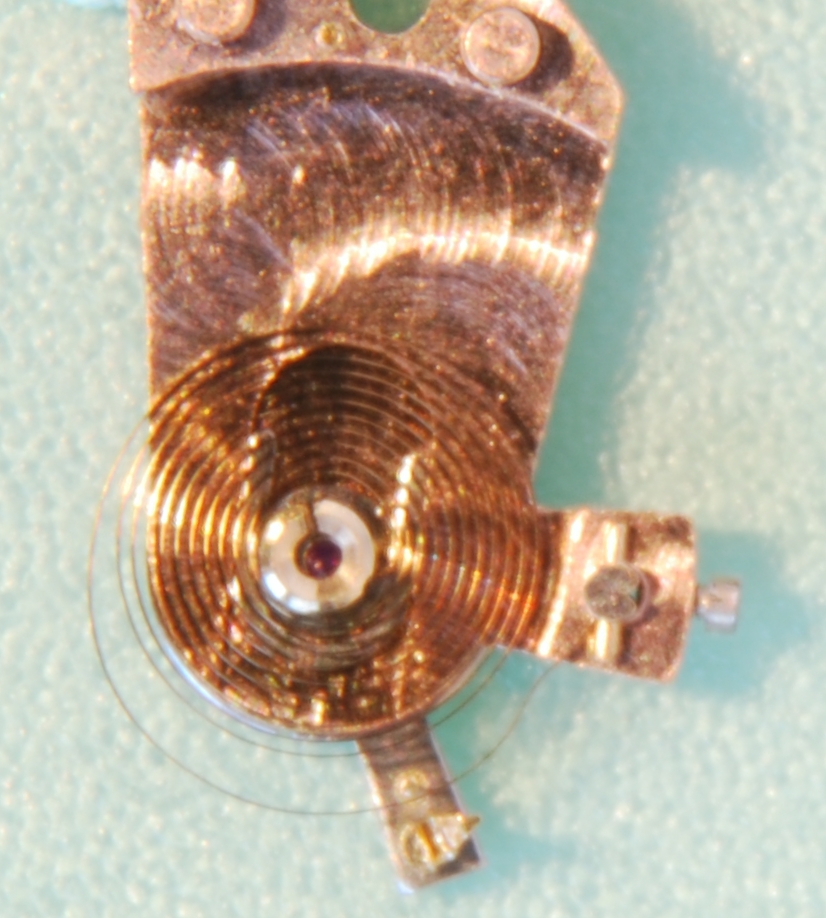

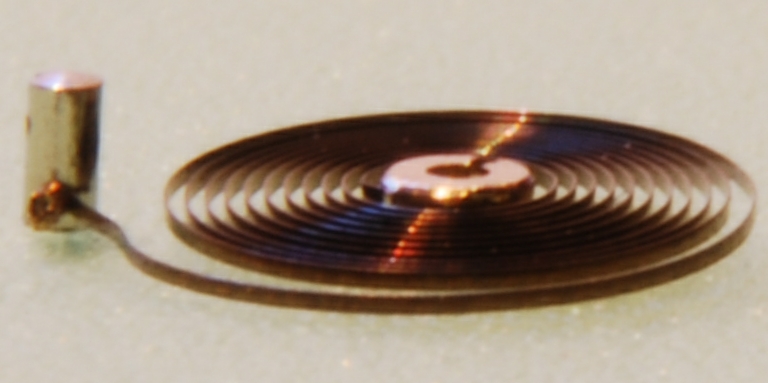

Balance spring correcting takes time to learn and the only way to get there is practice. Can you show us the spring condition now?

Cheers, Al