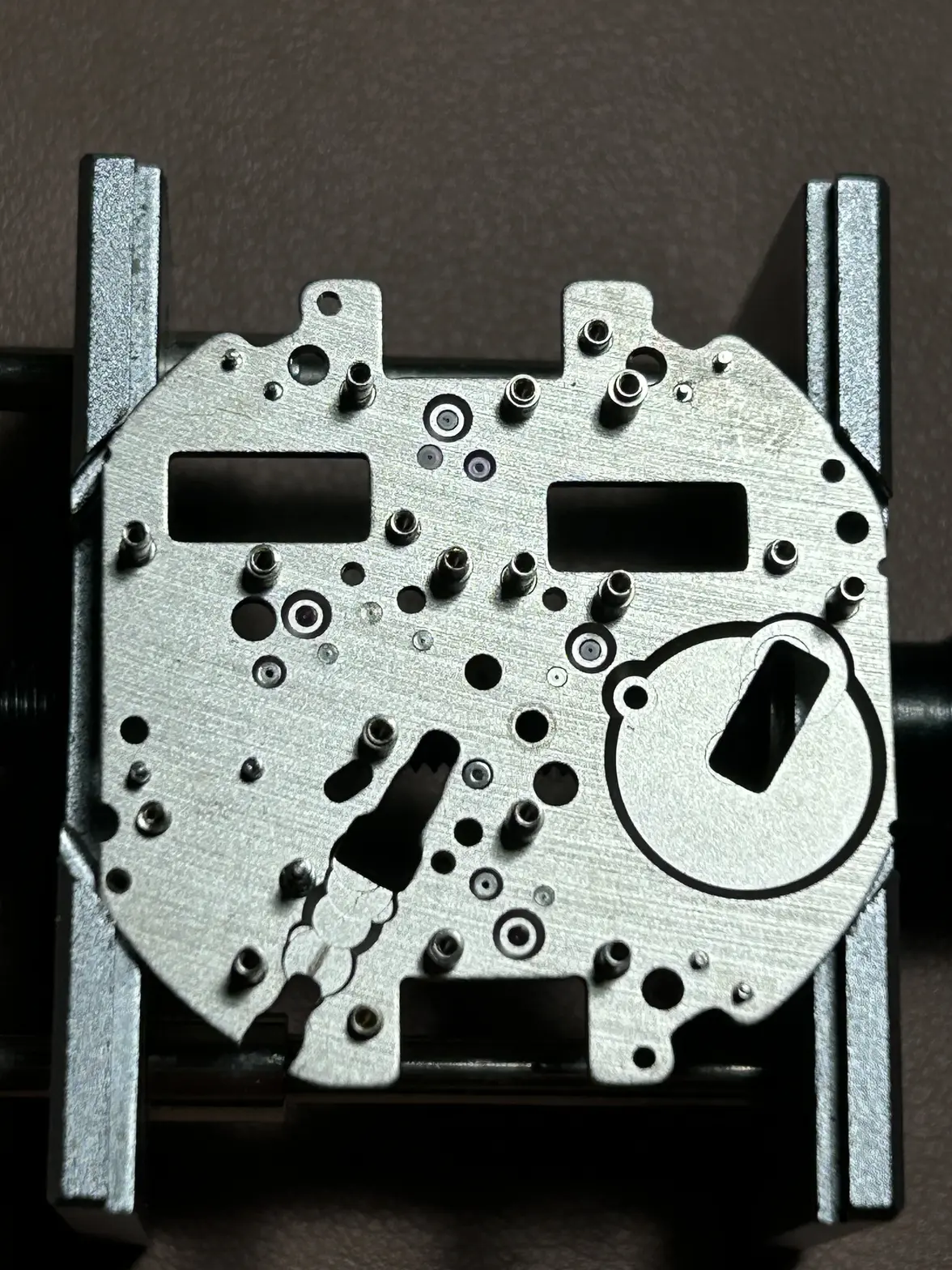

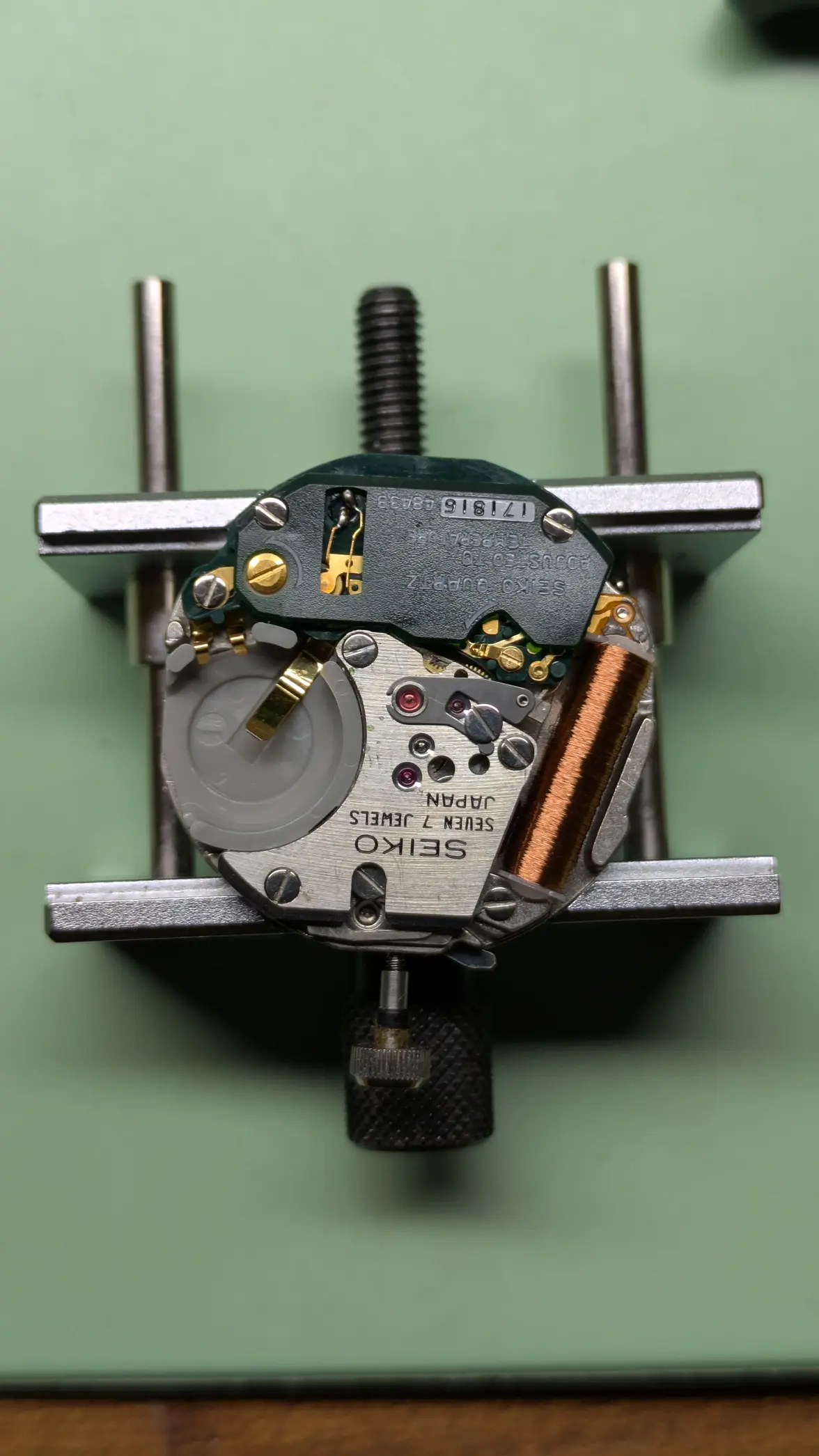

I serviced this Grand Seiko Quartz Cal 4843 at the weekend. Despite the case, dial and bracelet being in great condition, it was a non-runner that I bought for about £100. I don't have much experience mending quartz movements and have no real testing equipment, so went into it with some trepidation. The el-cheapo quartz tester from eBay detected an electric pulse, so I figured the gear train was jammed and potentially within my skill set to sort.

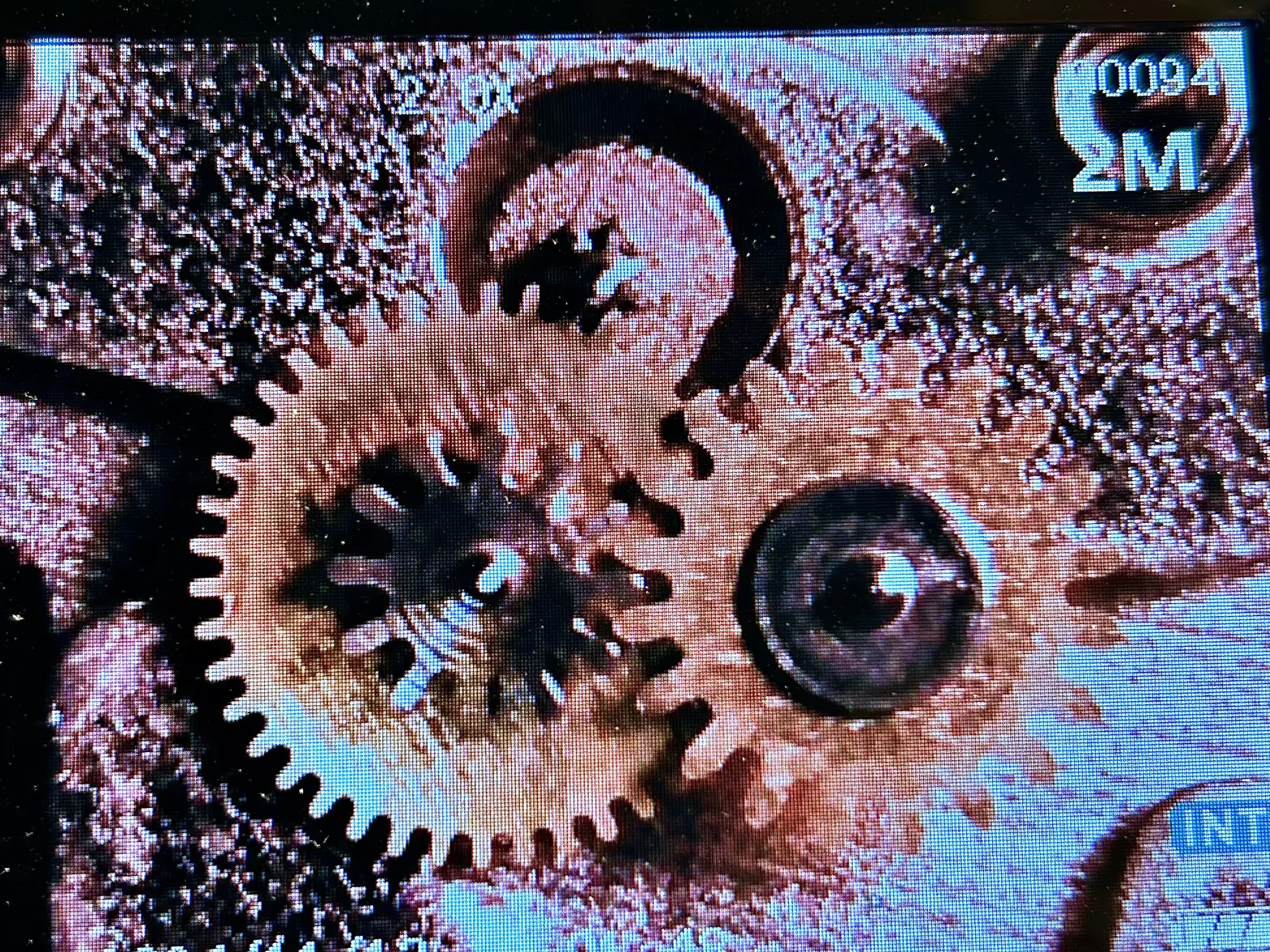

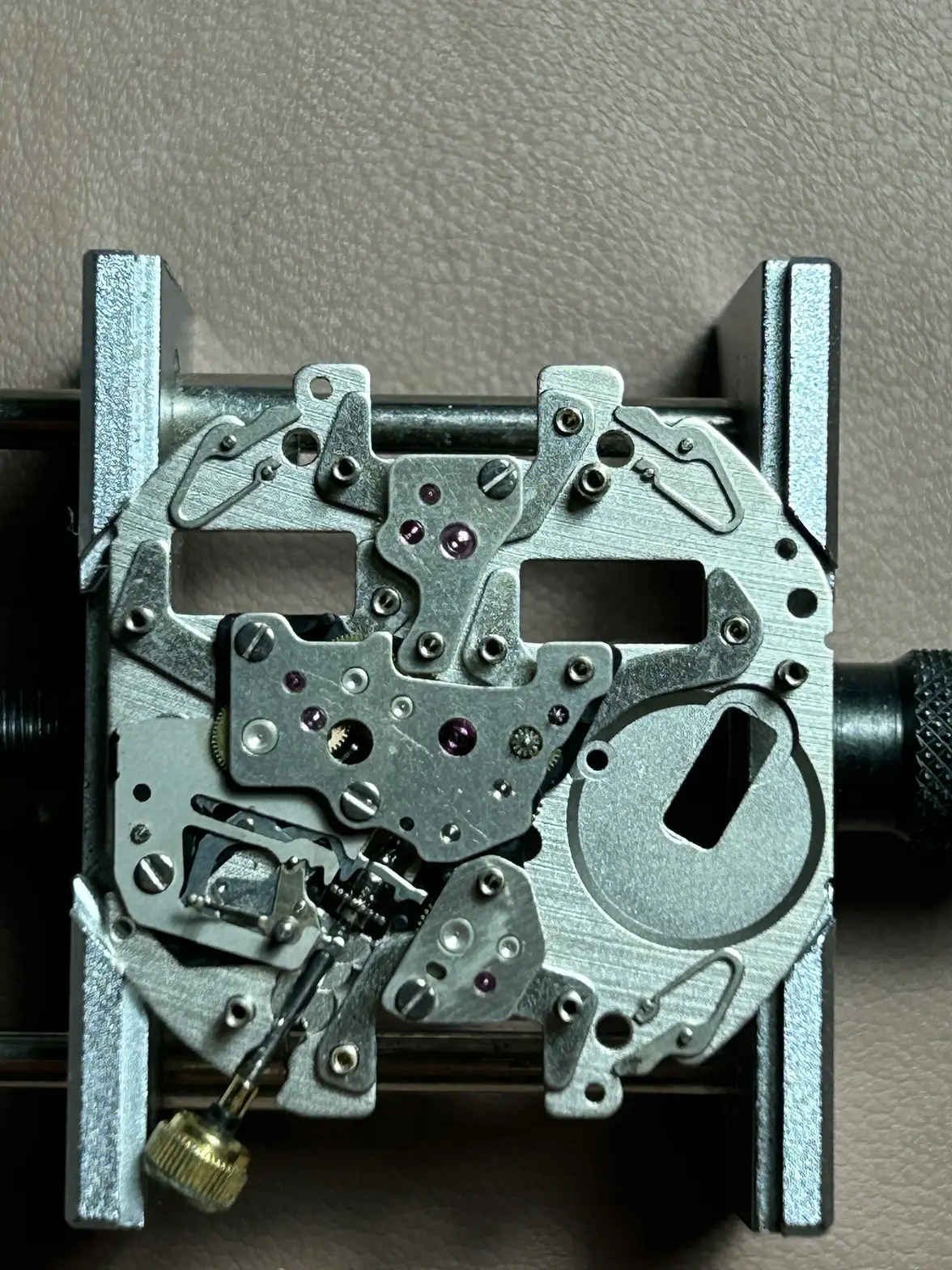

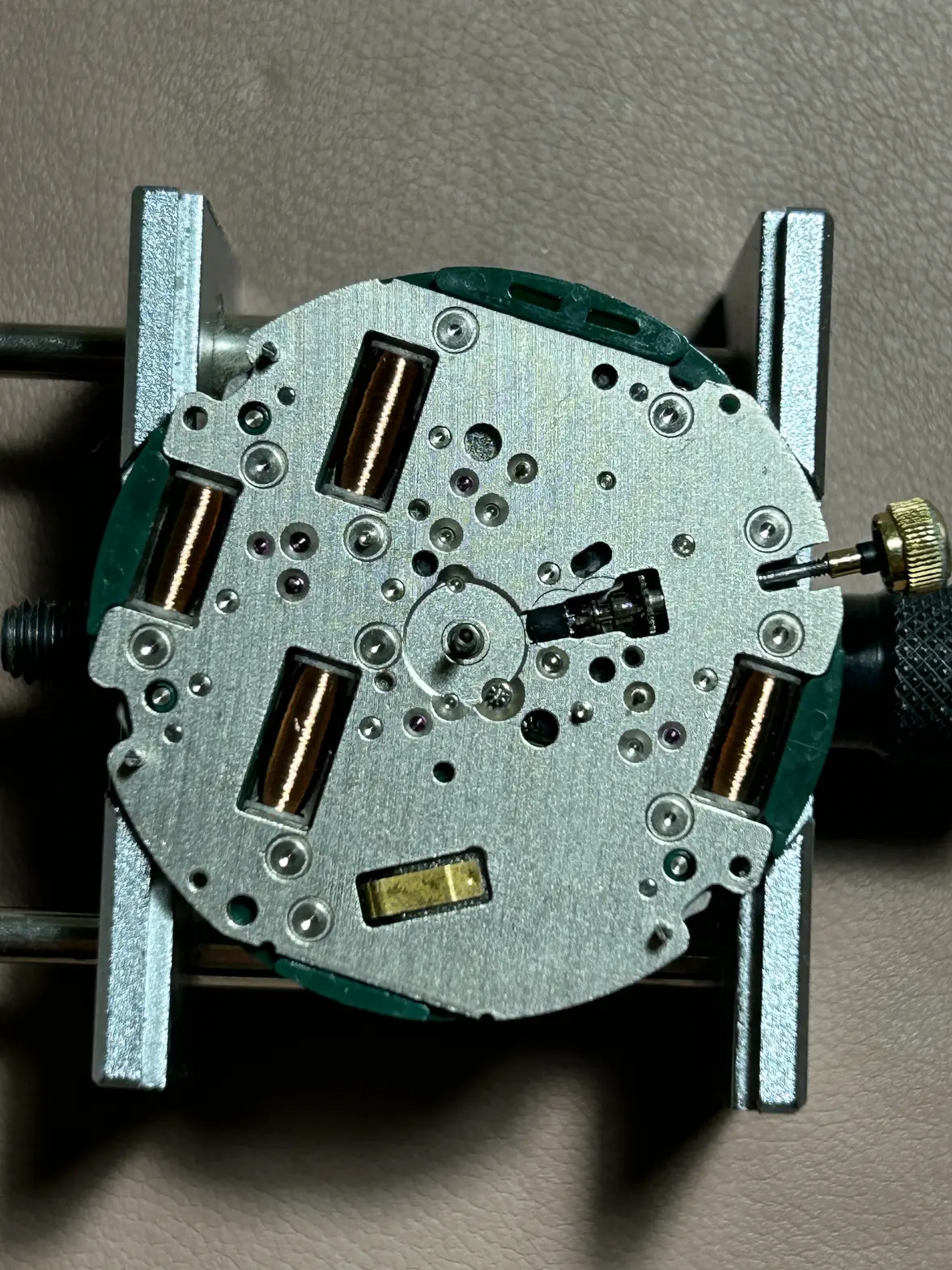

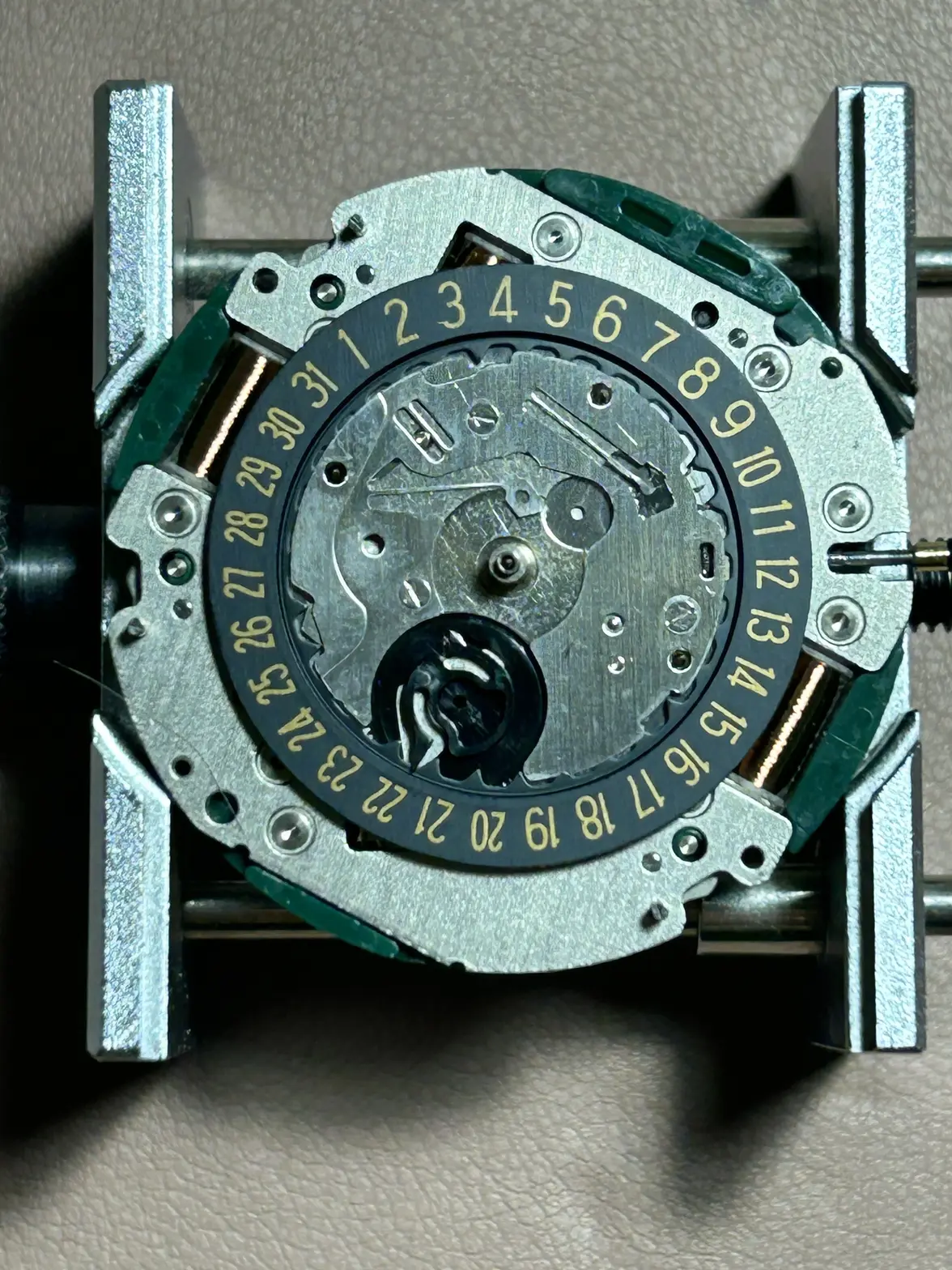

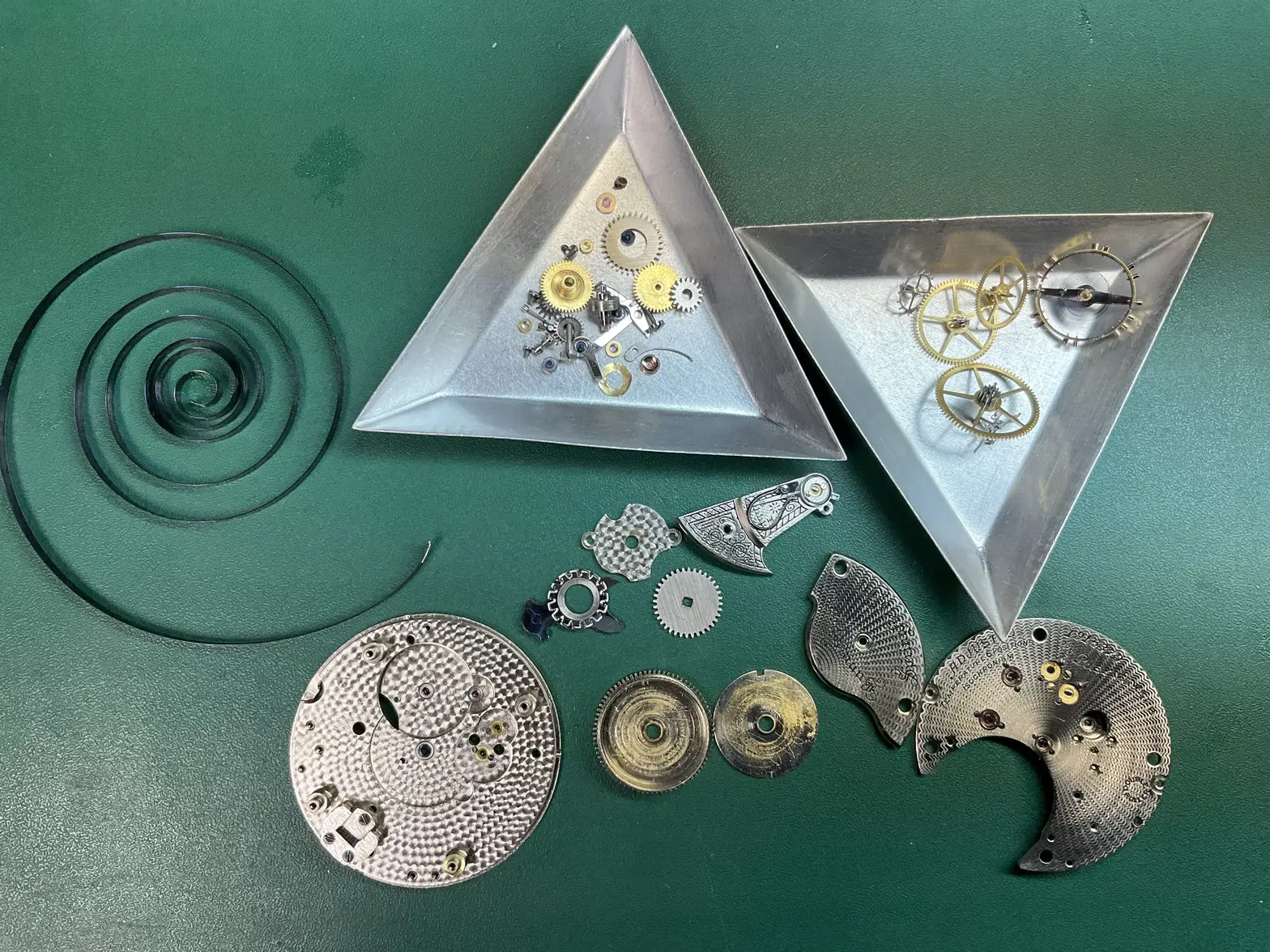

It was straightforward. In fact, the movement is modular in design, meaning that some of the more fiddly aspects came as preassembled units (e.g. seconds wheel jumper and the cam mechanism for setting the seconds hand at 10s intervals when pulling out the crown). The dial side of the movement was much the same as any mechanical watch.

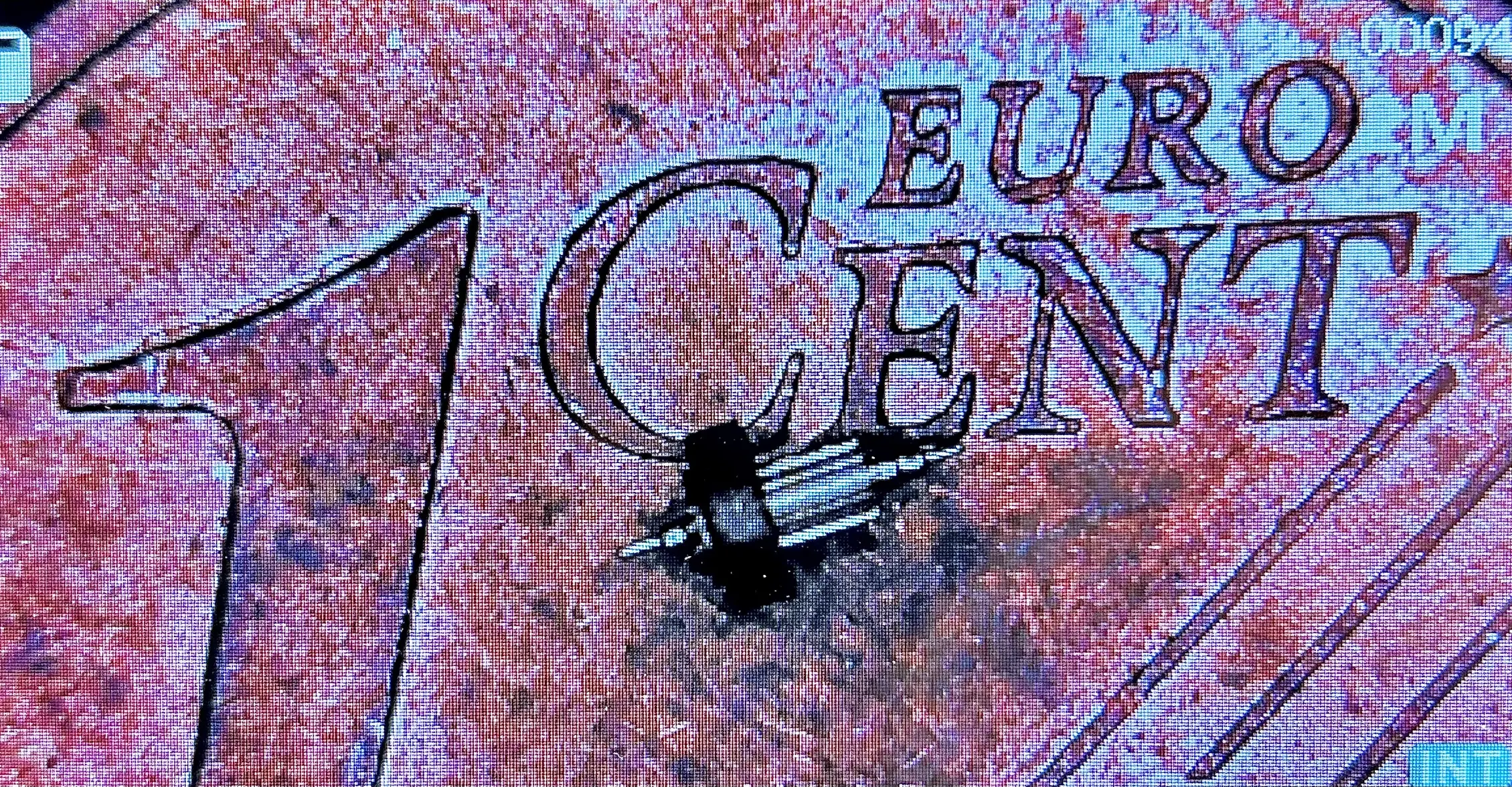

A green, sticky gloop was present on the bridges and on the gears themselves. Perhaps a leaky battery at some point? After careful cleaning, particularly of the gear teeth, and reassembly, it thankfully sprang back into life. Unfortunately, I don't have the quartz testing equipment, to be able to 'trim' the movement for accuracy or to check for current drain. So it's a bit of a job half-done. However, it hasn't lost a second over 48hrs, and is, thus far, working fine, so perhaps I'll get away with it...

These early high end Seiko quartz watches are great. Very well made movements with the 'grammar of design' cue taken from their (much more expensive) mechanical KS/GS counterparts.