JimInOz

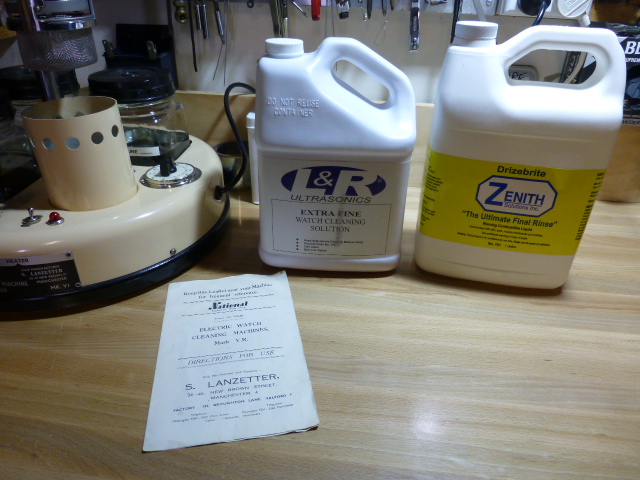

··Melbourne AustraliaSo after slacking off for so long, I decided to finish one of my projects. All of the stripping had been done and I just needed to put the parts through my watch cleaning machine. Although it’s fitted with a parts dryer, I didn’t like the thought of the rinsing solution dripping onto the very hot heater below, even after being spun dry in the jar.

I needed a hot air dryer, but the ones available are a bit expensive for a hobby, so I looked around the house to see if I could find anything that could be turned into a watch parts dryer. Luckily I just happened to find just the thing in the pantry, and the other half in Annie’s bathroom.

I already had a modified pop-top tin can with a small inside lip that was the perfect size to hold the baskets. All I had to do was make some holes for the can and the dryer.

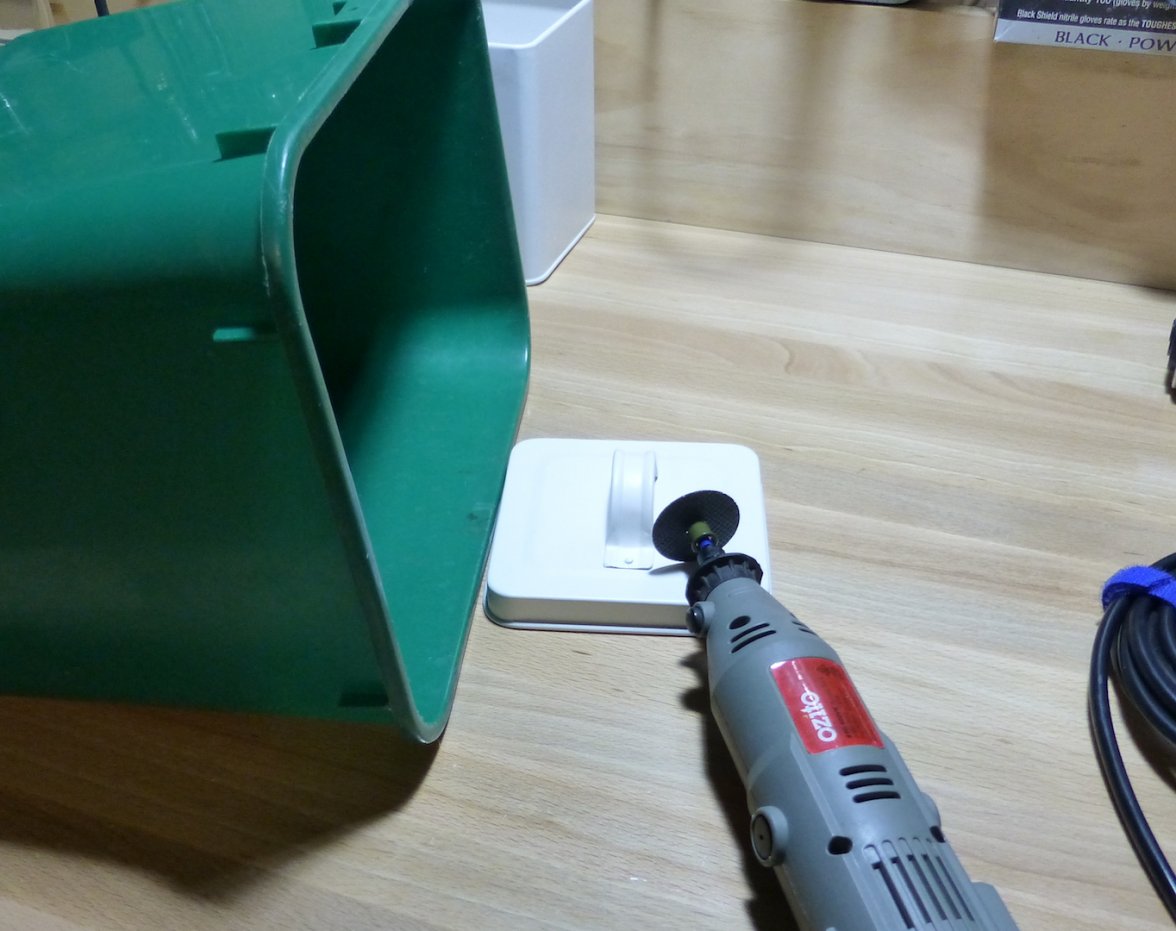

First to get rid of the pesky handle with a Dremel wheel.

With all of the useless bits removed, I could mark out the holes and start cutting.

I didn’t have a sheetmetal punch, so I had to improvise with a downlight hole cutter with a sharpened and hardened blade. The lid was clamped to the drill table and I slowly applied the blade. It was a bit scary with that big bar whizzing around, lucky my hair isn’t long enough to get caught up in it.

Success, a nice neat hole.

Just need to clean up the edges and fit the can into the lid.

The next hole in the side of the can was a bit harder and scarier. I couldn’t clamp it under the drill so I used a hand drill with the tin on a block of wood in the bench vice.

After holding my breath and wincing, I ended up with a clean hole in the side to allow the drier to direct air into the tin.

A quick clean of all of the parts and it was time for a functional check. With the dryer on low heat and low speed, a gentle stream of air is forced through the basket.

Even after 5 minutes, the temperature was steady between 37 to 41 degrees.

Well now that I’ve finished that, I’d better put it to use.

I needed a hot air dryer, but the ones available are a bit expensive for a hobby, so I looked around the house to see if I could find anything that could be turned into a watch parts dryer. Luckily I just happened to find just the thing in the pantry, and the other half in Annie’s bathroom.

I already had a modified pop-top tin can with a small inside lip that was the perfect size to hold the baskets. All I had to do was make some holes for the can and the dryer.

First to get rid of the pesky handle with a Dremel wheel.

With all of the useless bits removed, I could mark out the holes and start cutting.

I didn’t have a sheetmetal punch, so I had to improvise with a downlight hole cutter with a sharpened and hardened blade. The lid was clamped to the drill table and I slowly applied the blade. It was a bit scary with that big bar whizzing around, lucky my hair isn’t long enough to get caught up in it.

Success, a nice neat hole.

Just need to clean up the edges and fit the can into the lid.

The next hole in the side of the can was a bit harder and scarier. I couldn’t clamp it under the drill so I used a hand drill with the tin on a block of wood in the bench vice.

After holding my breath and wincing, I ended up with a clean hole in the side to allow the drier to direct air into the tin.

A quick clean of all of the parts and it was time for a functional check. With the dryer on low heat and low speed, a gentle stream of air is forced through the basket.

Even after 5 minutes, the temperature was steady between 37 to 41 degrees.

Well now that I’ve finished that, I’d better put it to use.

Edited: