ChrisN

·Thought I'd share this small adventure bringing a very cheap watch back to life. It's nothing special but, I've enjoyed reviving it.

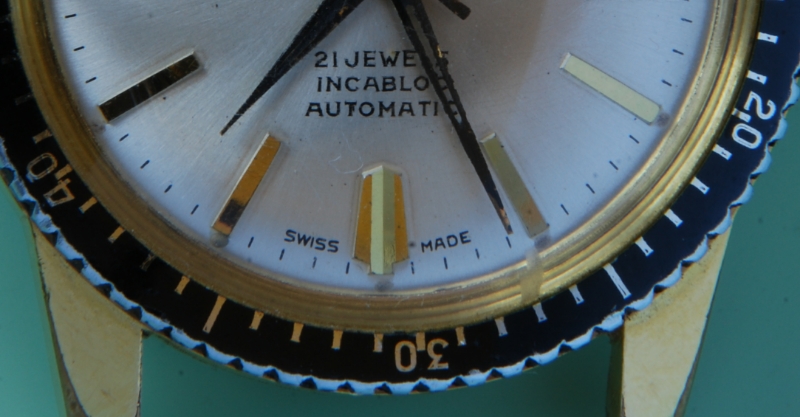

I'm not sure how I saw this on eBay but, I bid a maximum of €6.50 and won it for €1.00 + €3.50 postage. I find it a bit sad that people are selling things for €1 (less fees) but it seems they may have had someone look at it and declare it non salvageable. It was advertised as not working and I thought it might be nice to bring it back to life. Only one poor front shot to go by (listing picture at the end) but it looked like a late sixties dive 'style' watch. Clearly not a real diver but for this price, I'm not going to complain.

When it arrived, the crown/stem fell straight onto the floor but apart from that it looked complete and not too bad. The hands have been painted black which if they'd done it nicely is one thing but it's all thick hand painting and flaking off. The bezel rotates smoothly and is in good condition.

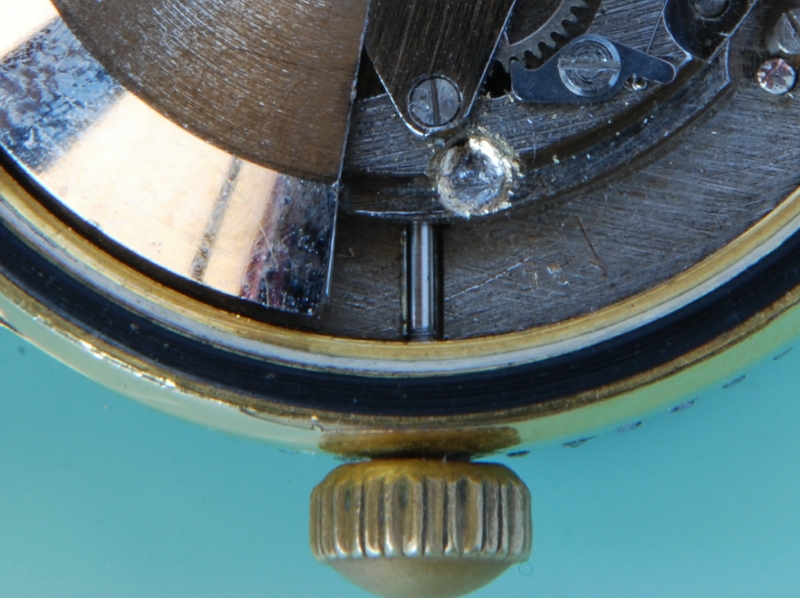

Open the back and there are some strange things going on here. Looks like someone has become angry with the setting lever screw (the one holding the crown and stem in) and has mangled it and the bridge. It is not attached to the setting lever so, this is why the crown falls out.

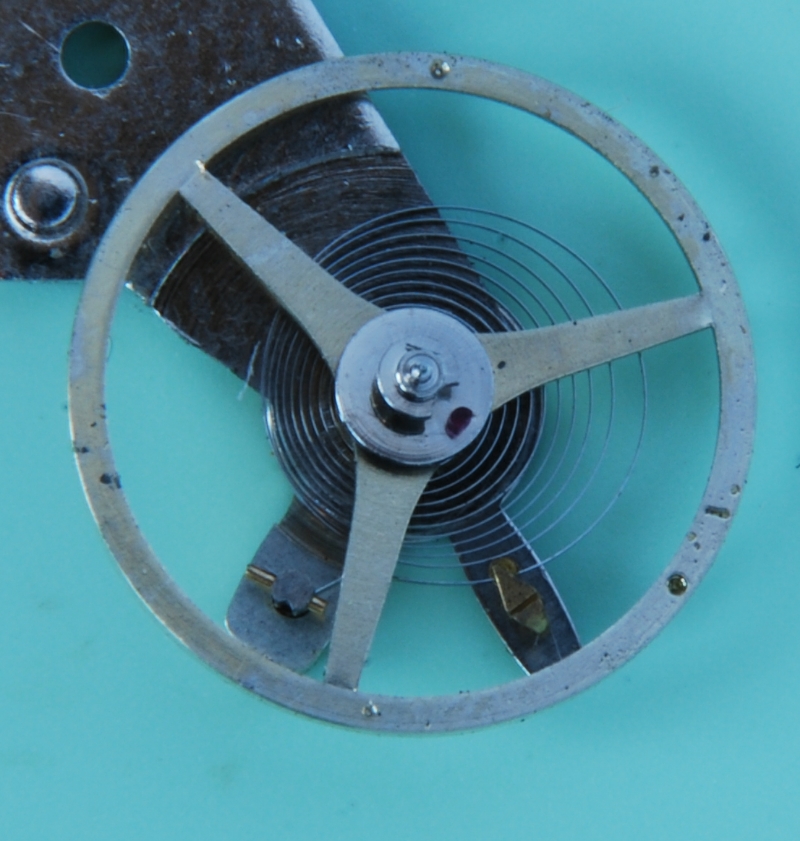

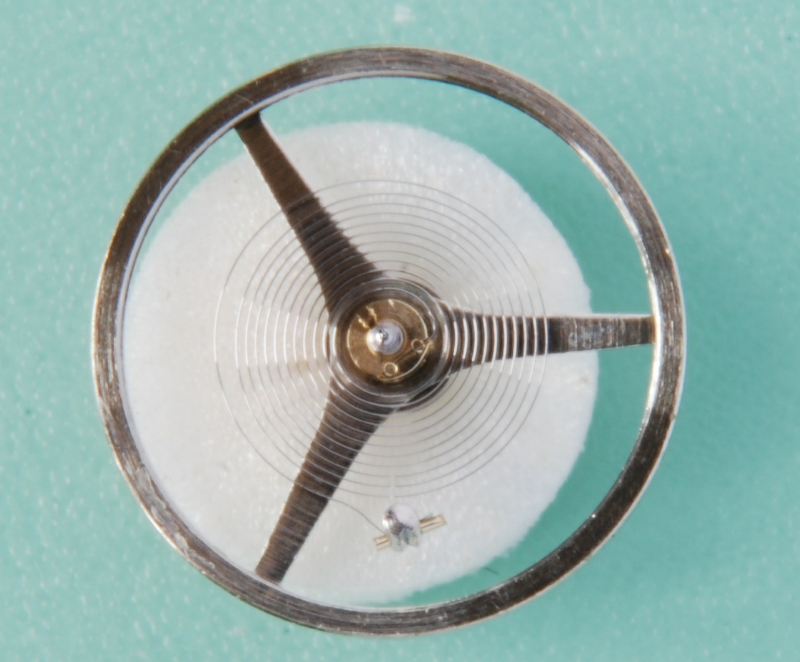

The balance spring is all off to one side. Good news is that it moves freely so no broken staff and it manfully tries, but without joy, to make the movement run.

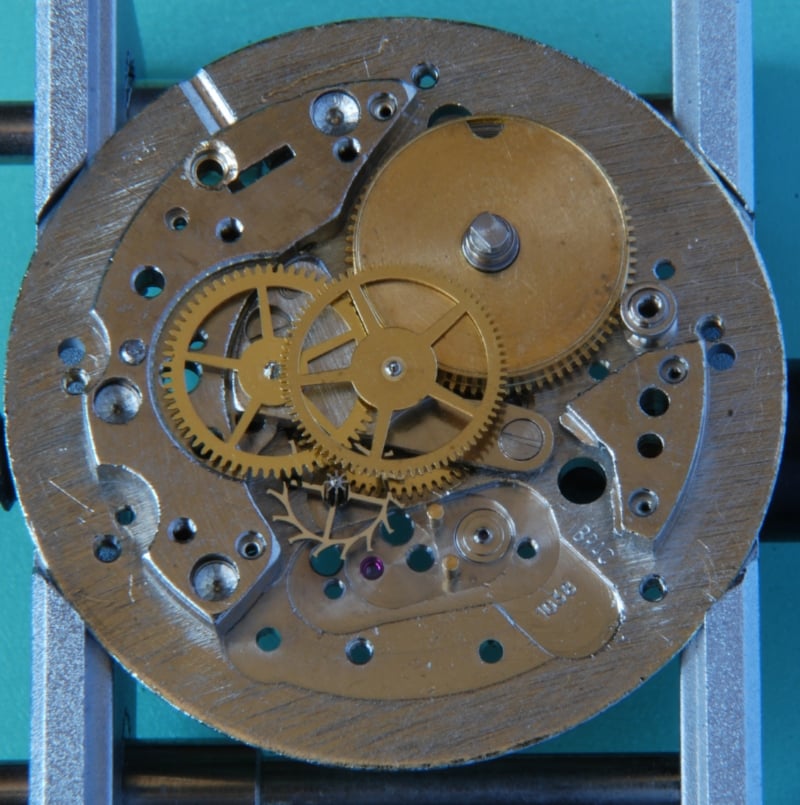

Rotor and mounting plate removed and this is the auto winder mechanism.

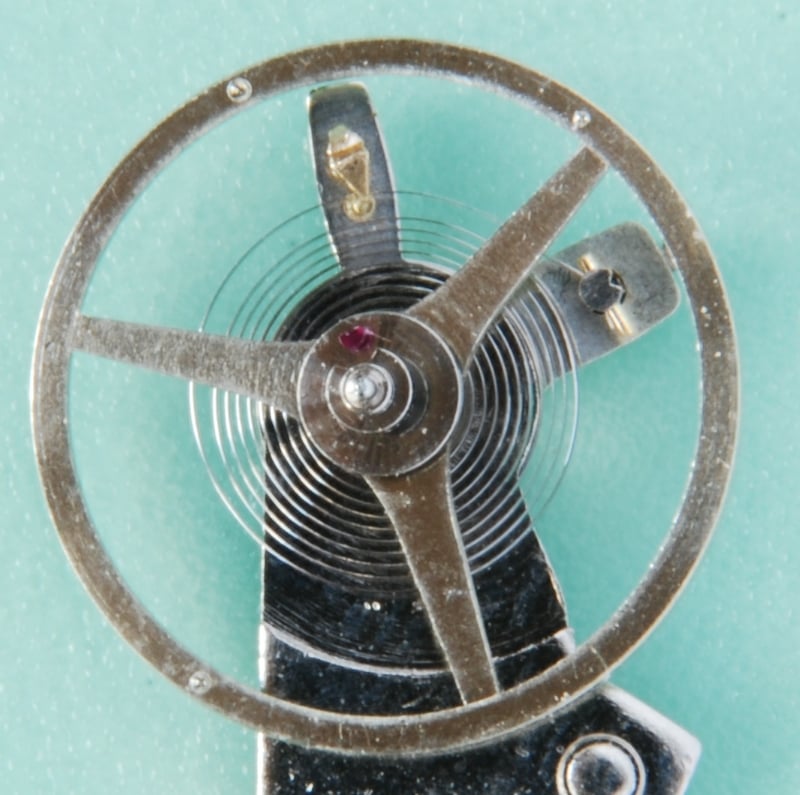

On the front side, the date mechanism is quite simple but, with that spring for the date jumper mounted as shown, the movement has no chance of changing the date because the force required is far too great. It needs to be slid across to work closer to the pivot of the date jumper arm. Someone has definitely had a go at fixing this movement but with little success.

It turns out that this is a BRAC 1038 with date and centre seconds running at 18000 A/h with a dual direction winding rotor mounted on a ball race bearing. That's not a bad spec although the finish is nothing to write home about. I've never heard of this company or calibre but Breitenbach is a town in Switzerland and it seems BRAC may have been based there. There is a huge list of BRAC calibres in my 'lift angles' spreadsheet but virtually no information comes up on the web. Cousins do list a stem and a non auto mainspring for a 1038 - seems strange for an auto. I cannot find any other spares at all so have to hope that everything is serviceable or repairable.

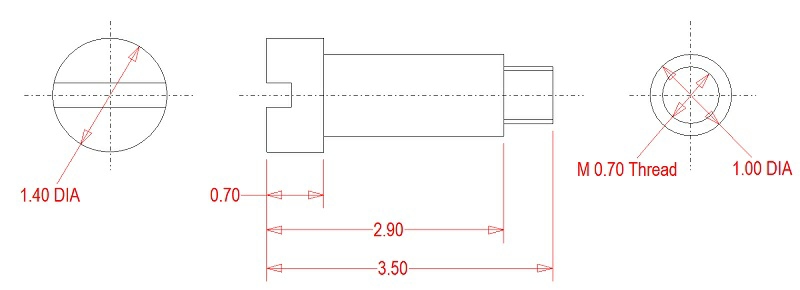

It came apart fairly easily except for the setting screw but, eventually I got the that out without damaging it further and later tried to cut a screw slot in what was left. I really need a new part and I have the necessary dimensions so might be a job for the future. If there's any tinkerer keen to try out their new lathe, feel free!

The hairspring is all off to one side. This is pre cleaning (it goes back in the plate for that).

But, removed from the stud carrier, it looks nice although wrong at the stud and without a sufficient dog leg out to the regulator. Just need to change the profile so it sits correctly.

Looking much better to me after some work. I think it still had a slight tilt at this point.

I couldn't find a new correct mainspring so decided to reuse the old one. Unfortunately, it winds the opposite way to most Swiss watches and I am too mean to buy winders for that direction so, use a right hand winder and load it in that. It is now the wrong way for pushing into the barrel but, I press it into a ring which came with a new 865 mainspring. Turn the ring over and push into the barrel - perfect.

Built the base movement and the reason it won't run became clear. When tightening the bridge screws with a movement that I've not seen running, I keep the train moving and with this one, the whole movement locks up on the last quarter turn of the screws. The reason was the escape wheel has no end shake at all. Fix that and all moves smoothly.

Funky looking pallet fork here.

Mounted the balance and it runs very nicely. Couple of tweaks for the beat error and it's soon running 270 degrees amplitude horizontal and 230 degrees vertical with a rate variation over five positions of 14 seconds, beat error 0.2 to 0.5 ms. Can't complain at that for full wind with this movement and old mainspring so move on.

Cleaned the paint off the minute hand and it looks not bad so I did all three and will leave them in gold colour but, they need lume.

One or two spots of dirty brown lume left on the dial so I cleaned those off. I toyed with using an orange lume to deflect from the damaged hands but decide to relume with a mixture of blue and green, making a sort of sea colour (only if you live in the Caribbean!) I've not tried to put the dots on a dial before but it's not too bad to do. I made various tests with different diameter tools - dip into the lume and lightly touch to the dial to get a nice raised blob.

Gave the case a clean and some of the plate is wearing off on the lugs but perfectly wearable. 10 minutes with Polywatch on the crystal and it's come up fine. Put everything back in the case and it's almost finished.

So, this is what I bought for less than the price of a beer- the only picture on the listing and a non runner:

And this is what I have now after some euros of cleaning fluids and lubricants. Still worth next to nothing and hardly fits in the exalted company on this forum but, it lives again! A bit of fun to bring this back to life and it will get some wrist time as a beater. Here on a rubber strap as it's the only 19mm I have to try it on.

With an obligatory Omega.

I believe Mithras made a few watches but probably closed down during the quartz period of the 1970s. Their company and logo are based on the God Mithras (the Roman soldiers' God), here seen killing a bull, for some reason......

Just know I will never meet anyone with another Mithras. OK, that may not be much of a claim to exclusivity.😗

Now my spending gets out of control as I need a case seal at €1, and splurge on a new stem plus crown at another €10. Finished pics when they arrive.

Cheers, Chris

I'm not sure how I saw this on eBay but, I bid a maximum of €6.50 and won it for €1.00 + €3.50 postage. I find it a bit sad that people are selling things for €1 (less fees) but it seems they may have had someone look at it and declare it non salvageable. It was advertised as not working and I thought it might be nice to bring it back to life. Only one poor front shot to go by (listing picture at the end) but it looked like a late sixties dive 'style' watch. Clearly not a real diver but for this price, I'm not going to complain.

When it arrived, the crown/stem fell straight onto the floor but apart from that it looked complete and not too bad. The hands have been painted black which if they'd done it nicely is one thing but it's all thick hand painting and flaking off. The bezel rotates smoothly and is in good condition.

Open the back and there are some strange things going on here. Looks like someone has become angry with the setting lever screw (the one holding the crown and stem in) and has mangled it and the bridge. It is not attached to the setting lever so, this is why the crown falls out.

The balance spring is all off to one side. Good news is that it moves freely so no broken staff and it manfully tries, but without joy, to make the movement run.

Rotor and mounting plate removed and this is the auto winder mechanism.

On the front side, the date mechanism is quite simple but, with that spring for the date jumper mounted as shown, the movement has no chance of changing the date because the force required is far too great. It needs to be slid across to work closer to the pivot of the date jumper arm. Someone has definitely had a go at fixing this movement but with little success.

It turns out that this is a BRAC 1038 with date and centre seconds running at 18000 A/h with a dual direction winding rotor mounted on a ball race bearing. That's not a bad spec although the finish is nothing to write home about. I've never heard of this company or calibre but Breitenbach is a town in Switzerland and it seems BRAC may have been based there. There is a huge list of BRAC calibres in my 'lift angles' spreadsheet but virtually no information comes up on the web. Cousins do list a stem and a non auto mainspring for a 1038 - seems strange for an auto. I cannot find any other spares at all so have to hope that everything is serviceable or repairable.

It came apart fairly easily except for the setting screw but, eventually I got the that out without damaging it further and later tried to cut a screw slot in what was left. I really need a new part and I have the necessary dimensions so might be a job for the future. If there's any tinkerer keen to try out their new lathe, feel free!

The hairspring is all off to one side. This is pre cleaning (it goes back in the plate for that).

But, removed from the stud carrier, it looks nice although wrong at the stud and without a sufficient dog leg out to the regulator. Just need to change the profile so it sits correctly.

Looking much better to me after some work. I think it still had a slight tilt at this point.

I couldn't find a new correct mainspring so decided to reuse the old one. Unfortunately, it winds the opposite way to most Swiss watches and I am too mean to buy winders for that direction so, use a right hand winder and load it in that. It is now the wrong way for pushing into the barrel but, I press it into a ring which came with a new 865 mainspring. Turn the ring over and push into the barrel - perfect.

Built the base movement and the reason it won't run became clear. When tightening the bridge screws with a movement that I've not seen running, I keep the train moving and with this one, the whole movement locks up on the last quarter turn of the screws. The reason was the escape wheel has no end shake at all. Fix that and all moves smoothly.

Funky looking pallet fork here.

Mounted the balance and it runs very nicely. Couple of tweaks for the beat error and it's soon running 270 degrees amplitude horizontal and 230 degrees vertical with a rate variation over five positions of 14 seconds, beat error 0.2 to 0.5 ms. Can't complain at that for full wind with this movement and old mainspring so move on.

Cleaned the paint off the minute hand and it looks not bad so I did all three and will leave them in gold colour but, they need lume.

One or two spots of dirty brown lume left on the dial so I cleaned those off. I toyed with using an orange lume to deflect from the damaged hands but decide to relume with a mixture of blue and green, making a sort of sea colour (only if you live in the Caribbean!) I've not tried to put the dots on a dial before but it's not too bad to do. I made various tests with different diameter tools - dip into the lume and lightly touch to the dial to get a nice raised blob.

Gave the case a clean and some of the plate is wearing off on the lugs but perfectly wearable. 10 minutes with Polywatch on the crystal and it's come up fine. Put everything back in the case and it's almost finished.

So, this is what I bought for less than the price of a beer- the only picture on the listing and a non runner:

And this is what I have now after some euros of cleaning fluids and lubricants. Still worth next to nothing and hardly fits in the exalted company on this forum but, it lives again! A bit of fun to bring this back to life and it will get some wrist time as a beater. Here on a rubber strap as it's the only 19mm I have to try it on.

With an obligatory Omega.

I believe Mithras made a few watches but probably closed down during the quartz period of the 1970s. Their company and logo are based on the God Mithras (the Roman soldiers' God), here seen killing a bull, for some reason......

Just know I will never meet anyone with another Mithras. OK, that may not be much of a claim to exclusivity.😗

Now my spending gets out of control as I need a case seal at €1, and splurge on a new stem plus crown at another €10. Finished pics when they arrive.

Cheers, Chris