JimInOz

··Melbourne AustraliaAfter seeing Al's thread on a couple of lathe projects, I got myself fired up to do something about the darn shock mount springs that are usually a PITA to install.

Off to the garage I went and looked around and found a bit of 2.7mm ø bronze rod from an old clock chime.

I put the rod in a collet, tidied up the tip of my graver and started cutting a taper on the rod.

A few minutes later I was getting there.

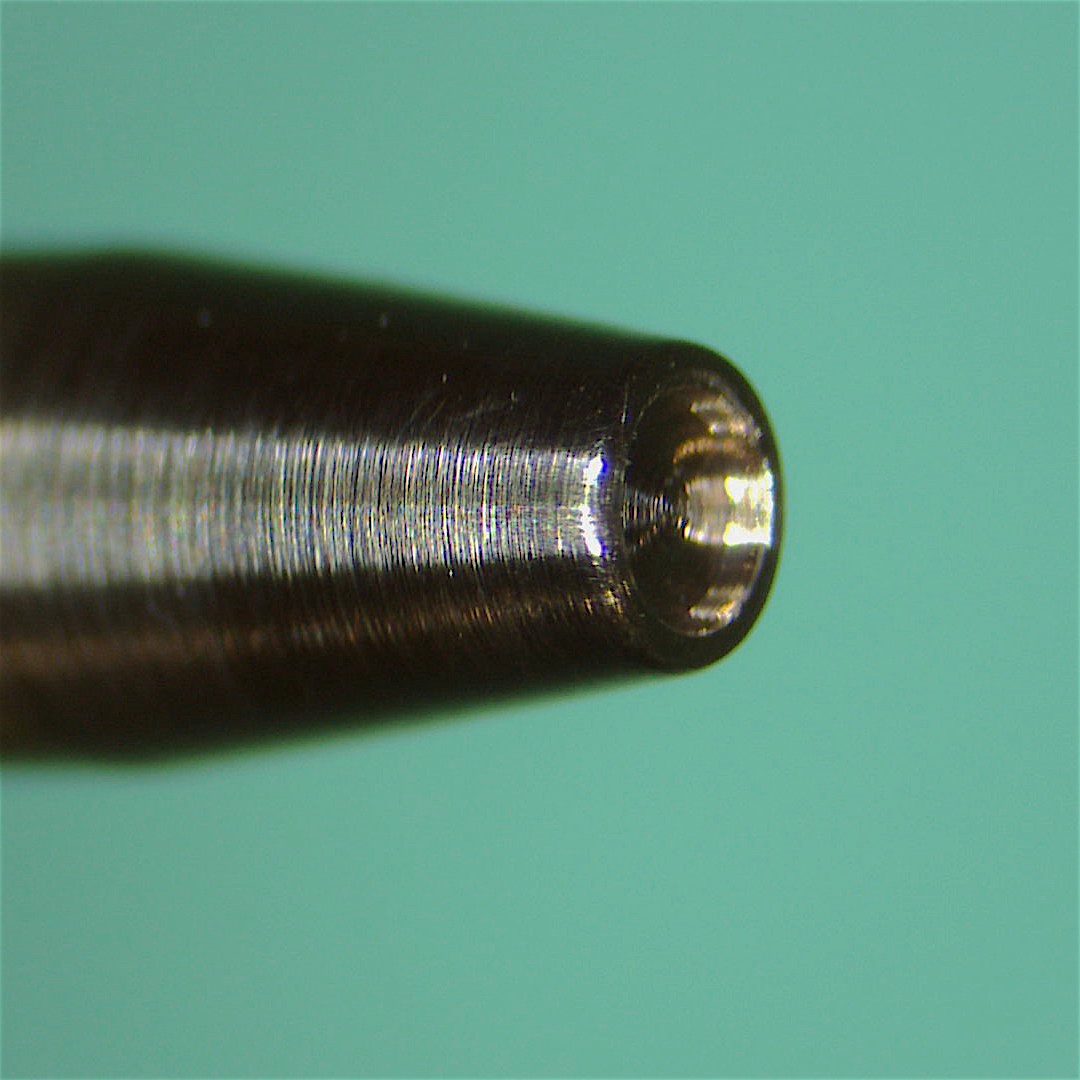

I found the hardest thing was getting rid of the tiny centre pimple when cutting the hole in the end of the rod.

Darn phone wouldn't focus on the tip!

After getting it down to size and cleaning up the hole, I was all done.

Viola! A new tool that cost me nothing but time. And electricity. And tooling costs.

A close up of the tip for my pass/fail test 😉.

Cheers

Jim

Off to the garage I went and looked around and found a bit of 2.7mm ø bronze rod from an old clock chime.

I put the rod in a collet, tidied up the tip of my graver and started cutting a taper on the rod.

A few minutes later I was getting there.

I found the hardest thing was getting rid of the tiny centre pimple when cutting the hole in the end of the rod.

Darn phone wouldn't focus on the tip!

After getting it down to size and cleaning up the hole, I was all done.

Viola! A new tool that cost me nothing but time. And electricity. And tooling costs.

A close up of the tip for my pass/fail test 😉.

Cheers

Jim