JimInOz

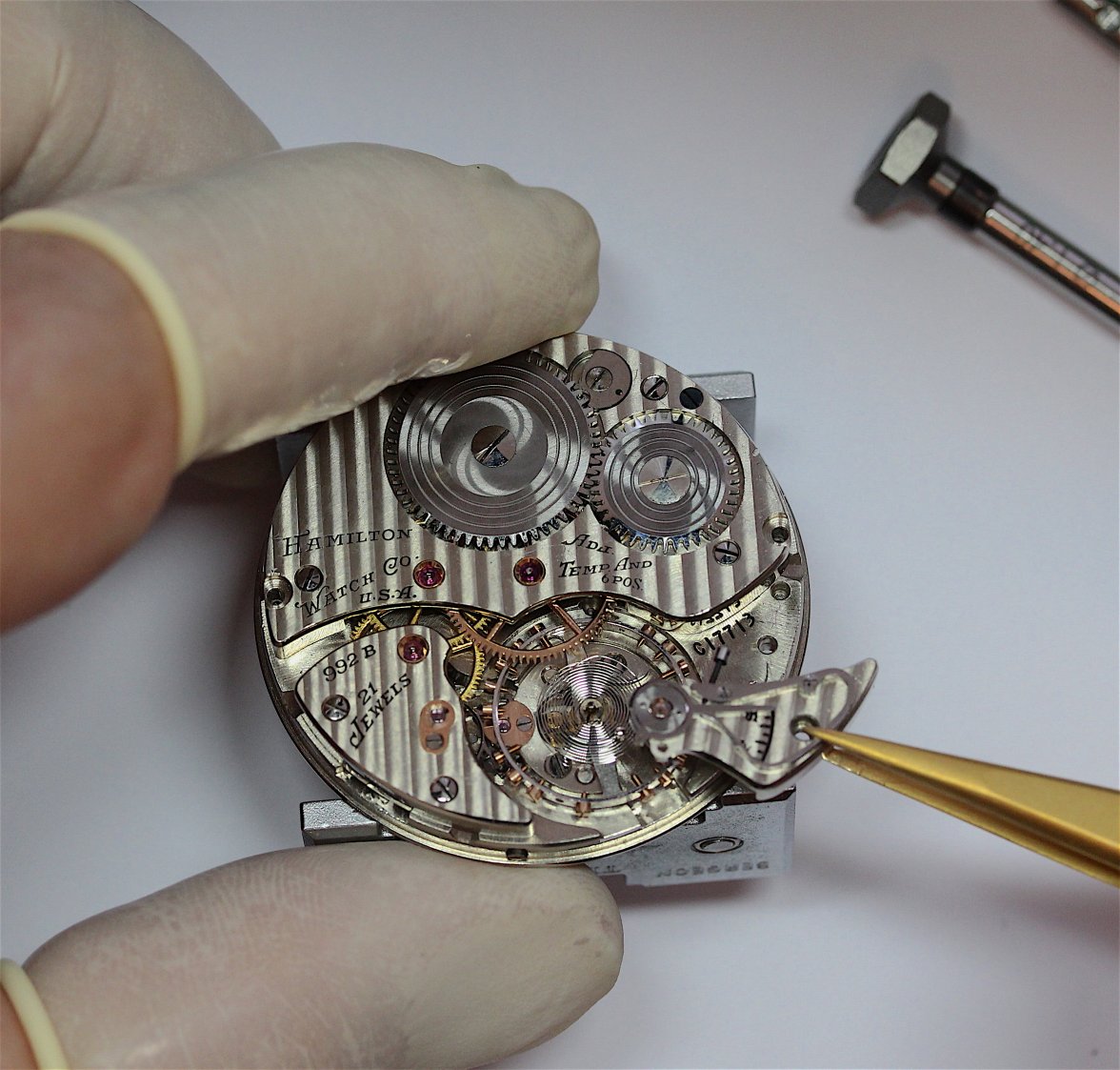

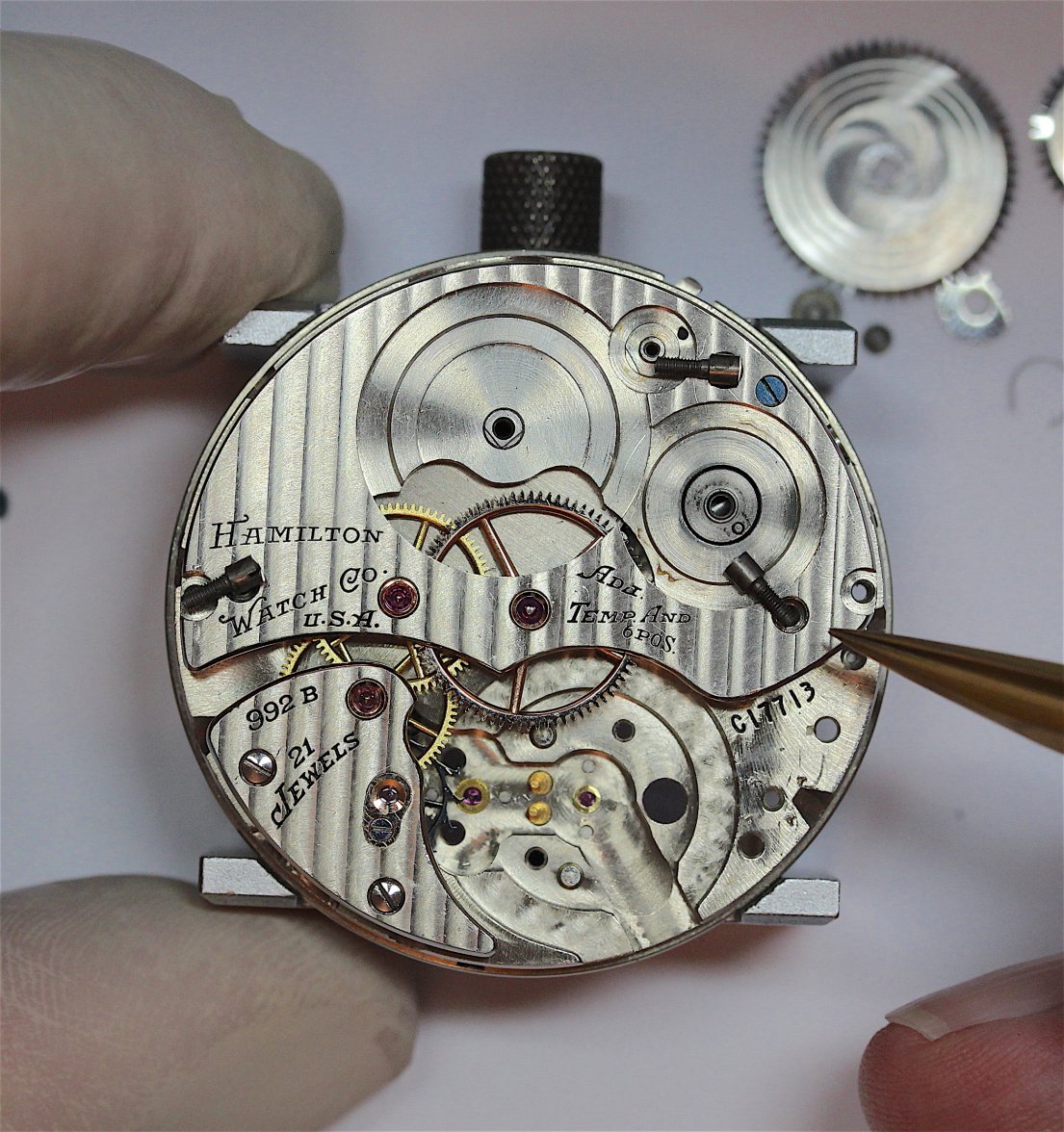

··Melbourne AustraliaI got this Hamilton 992B Railway Special late last year and was rather pleaded with it.

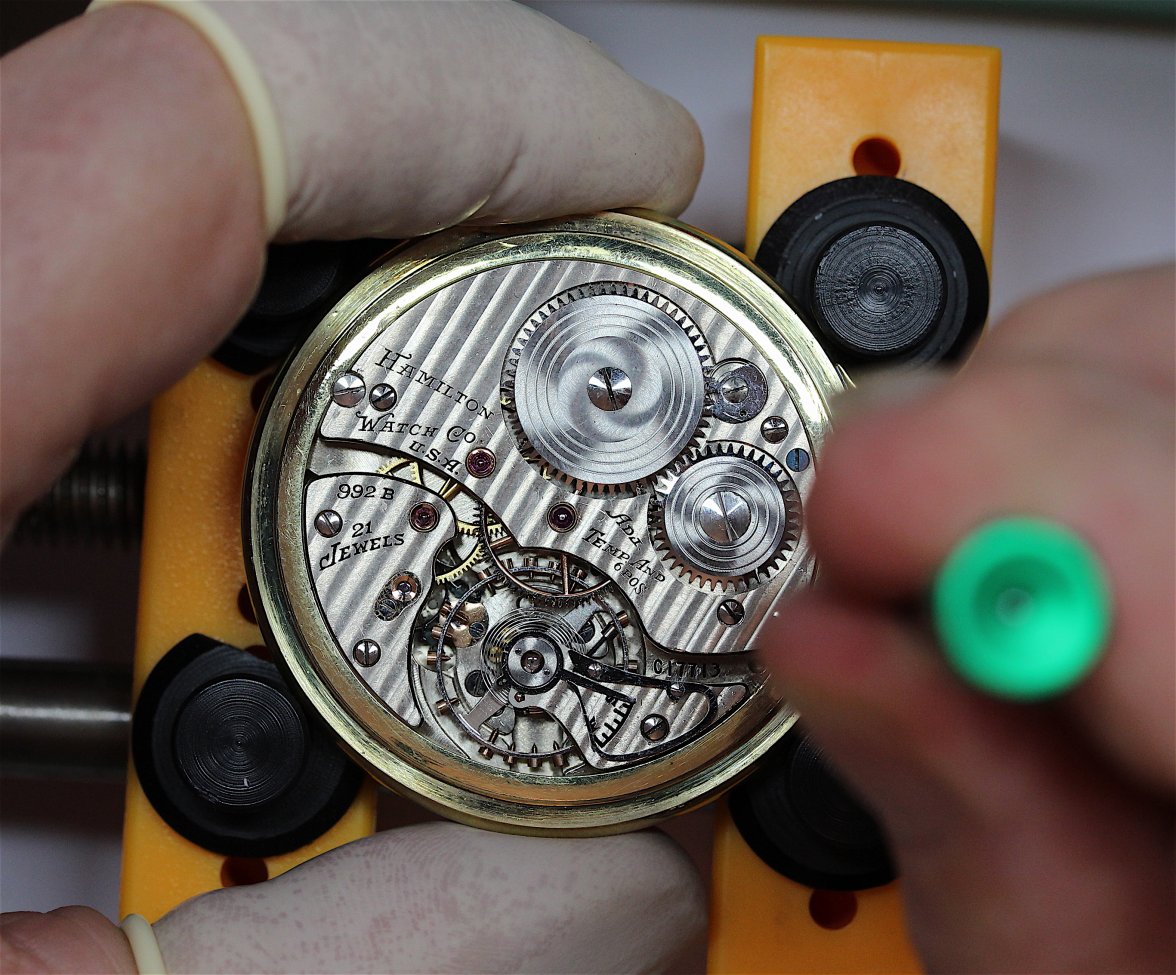

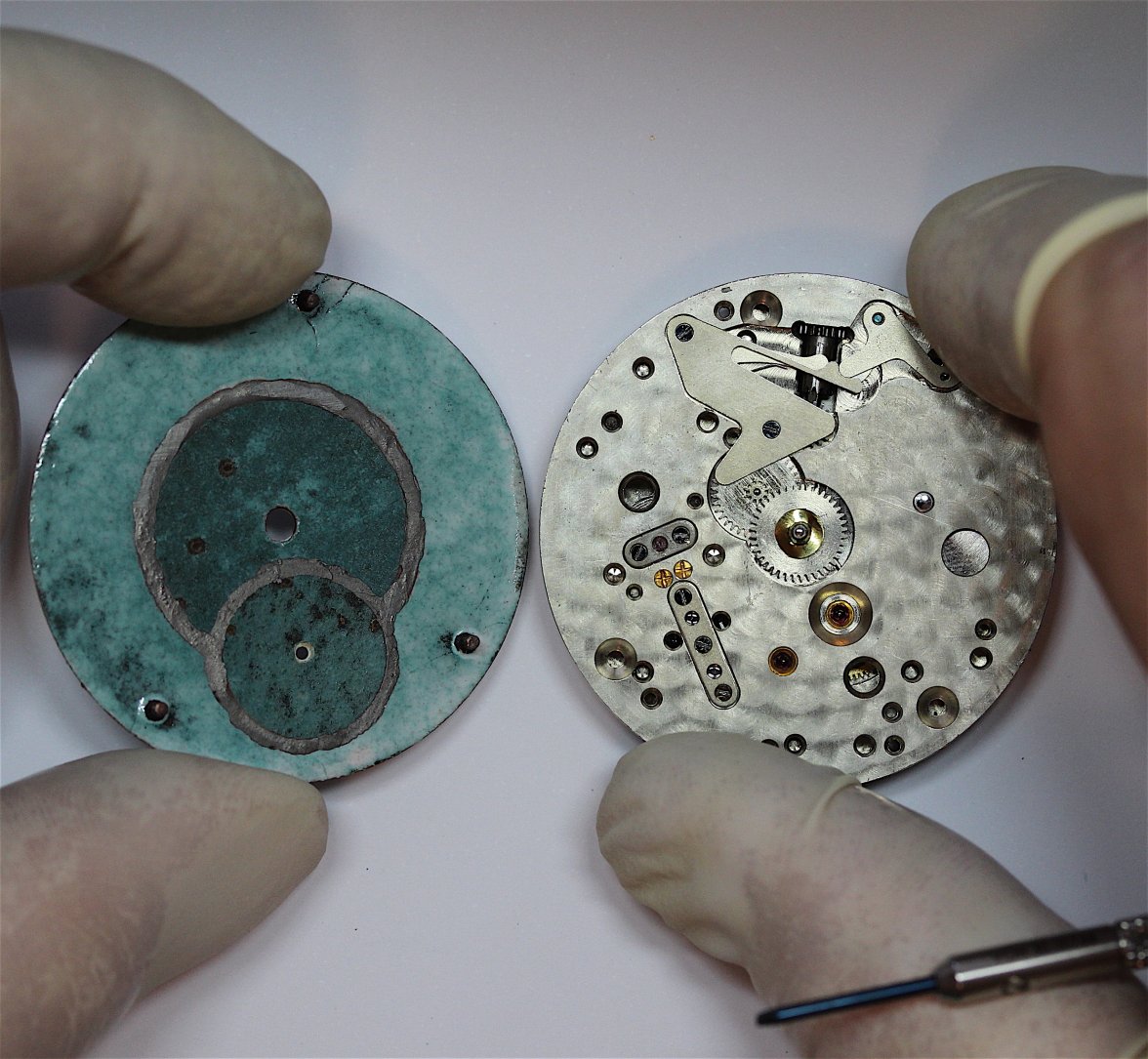

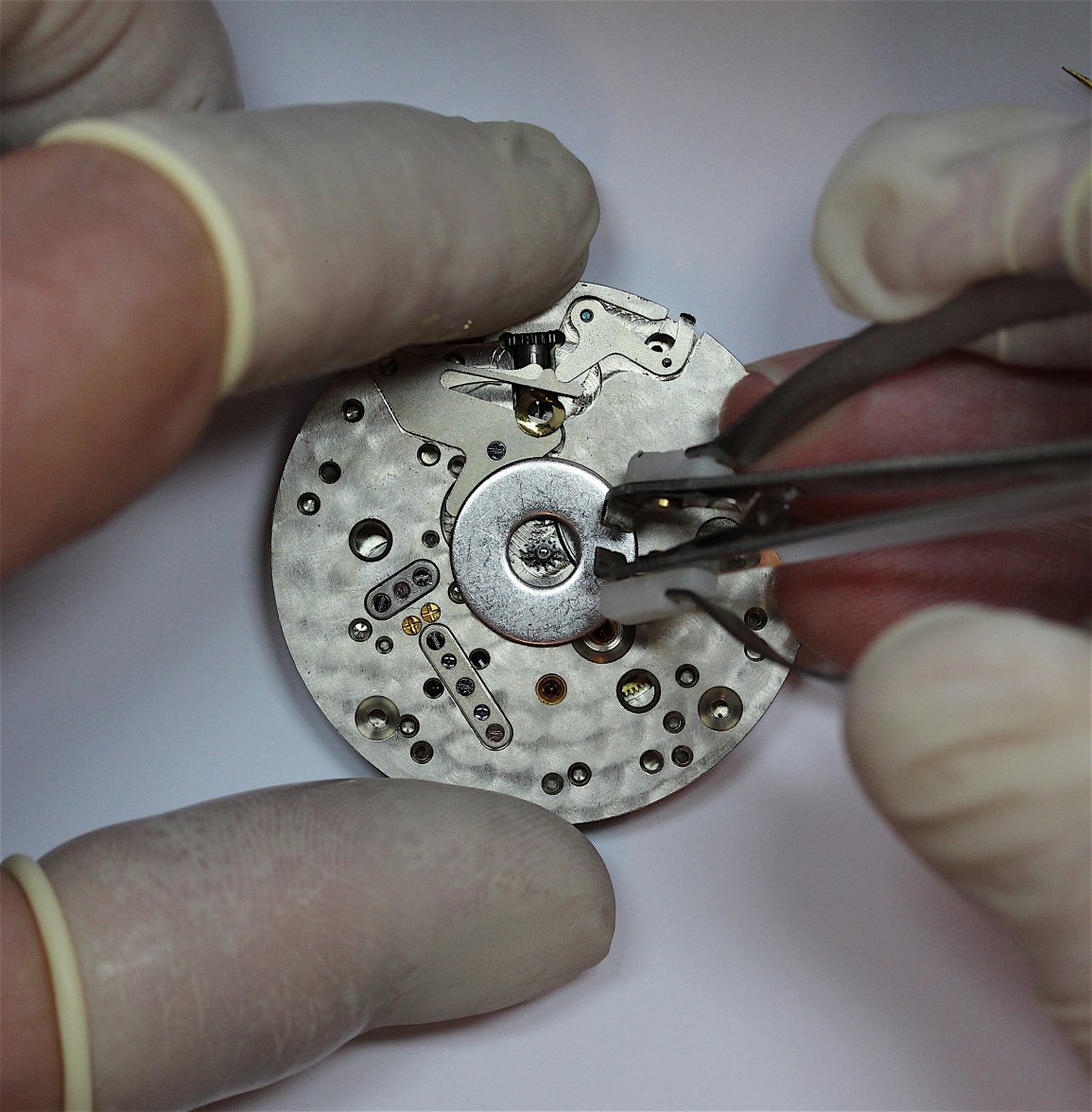

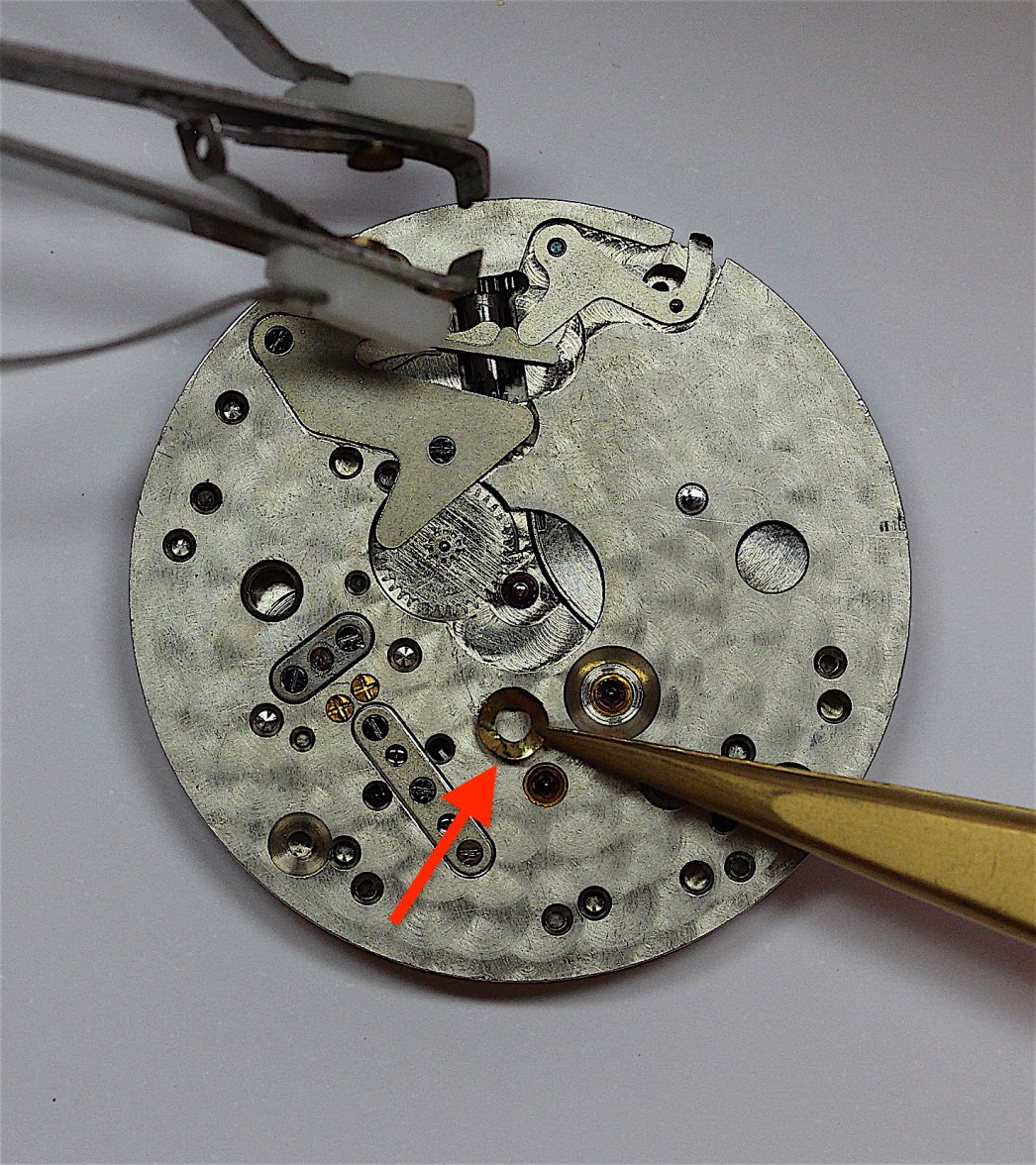

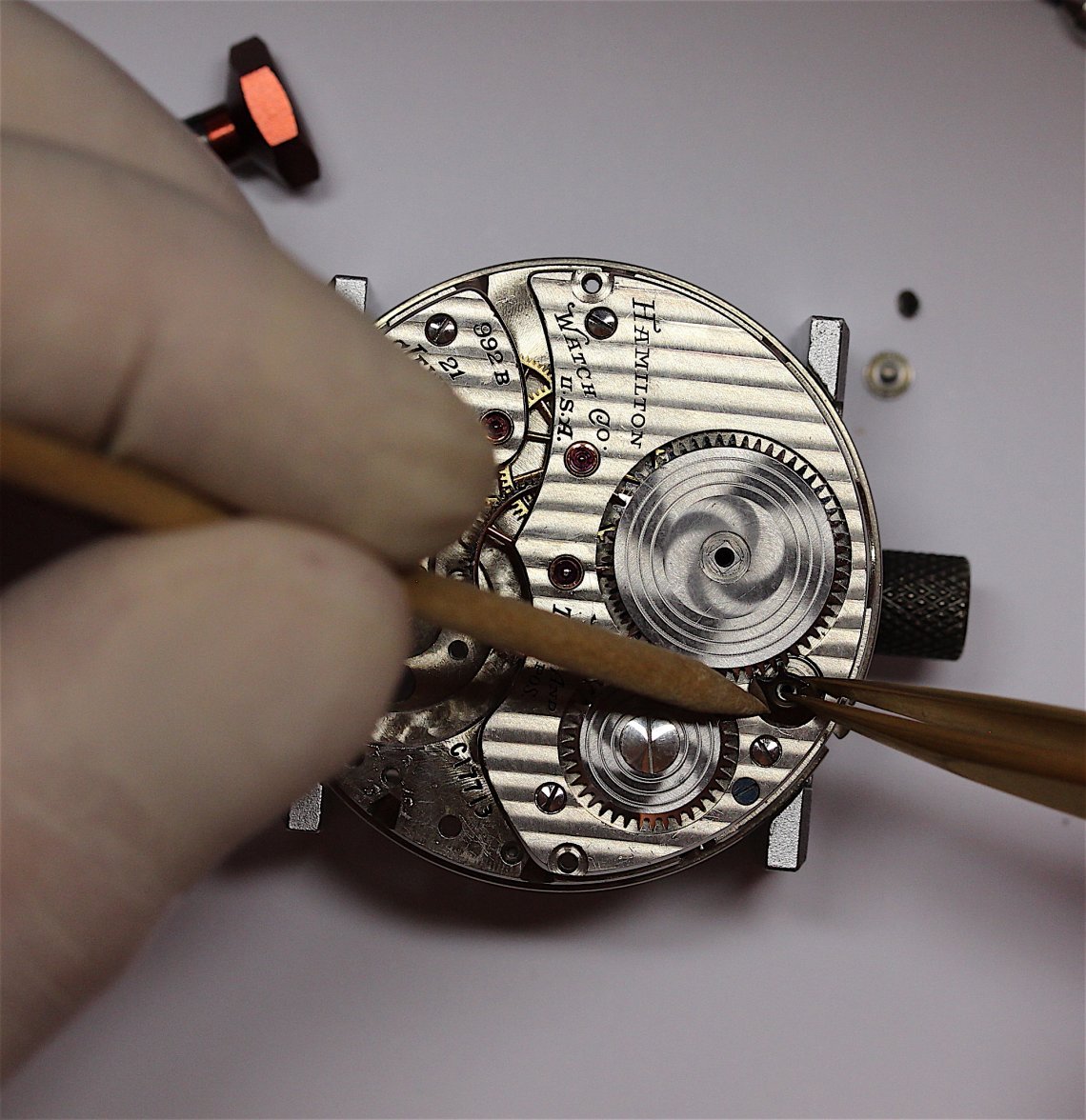

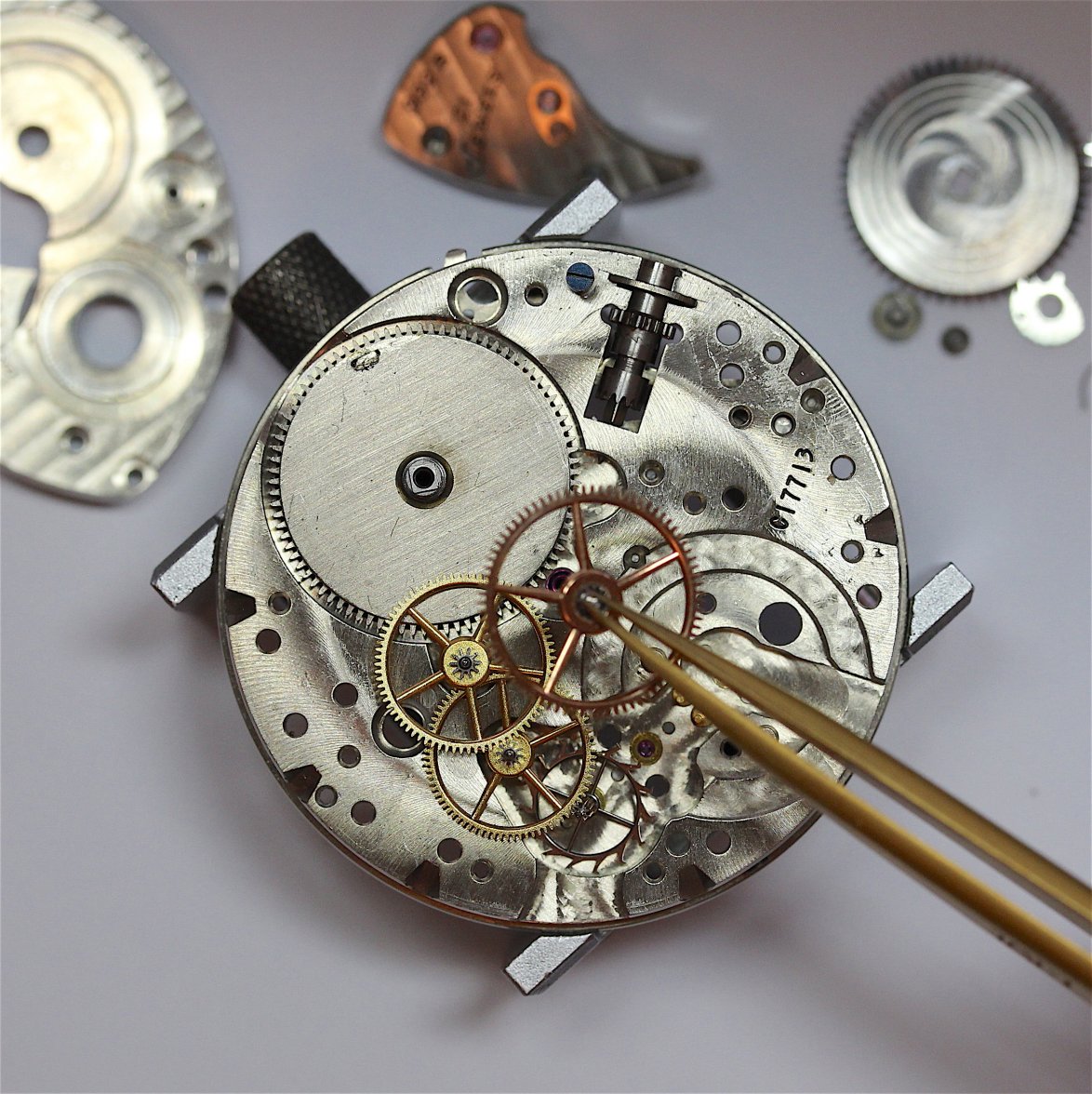

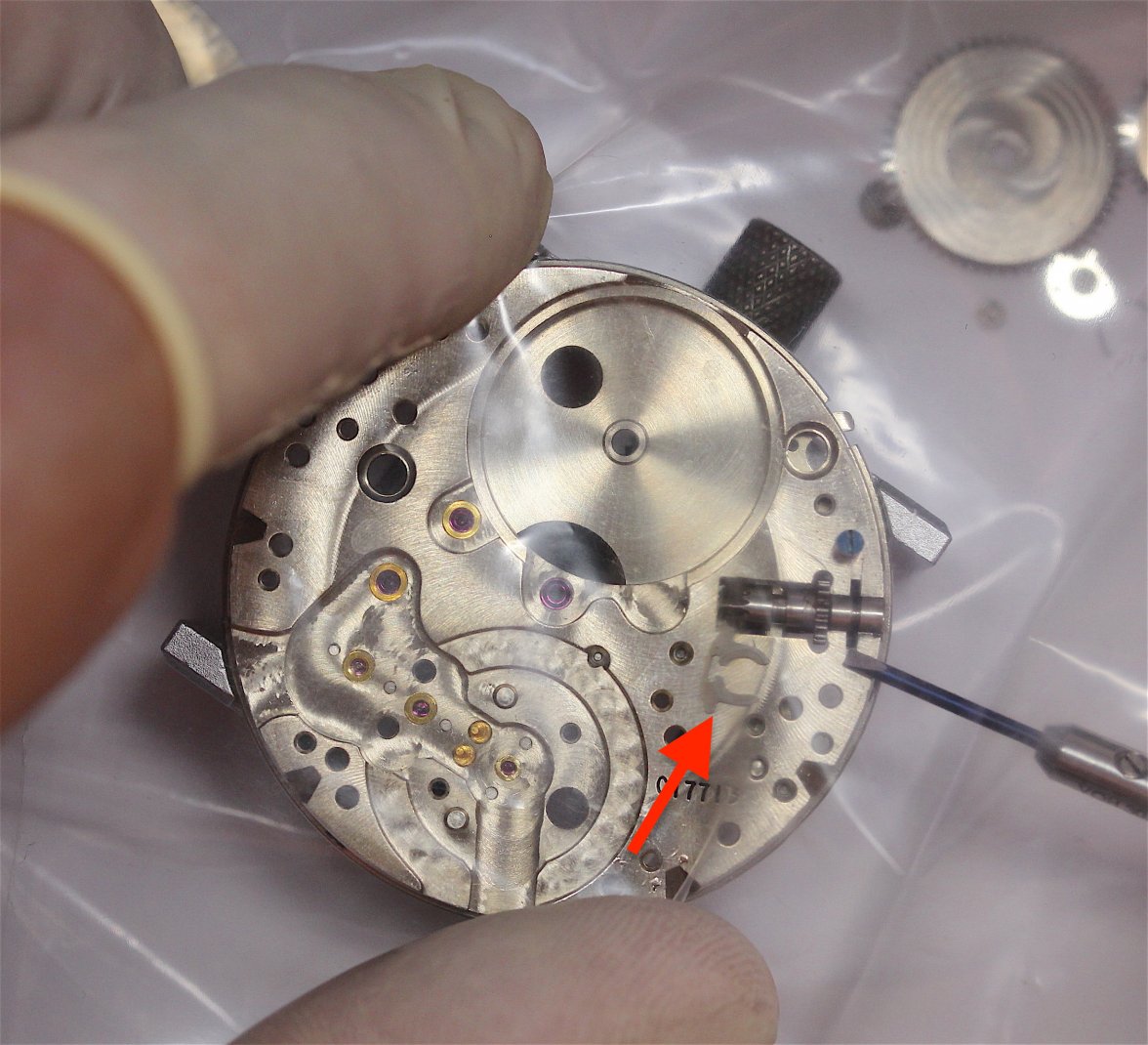

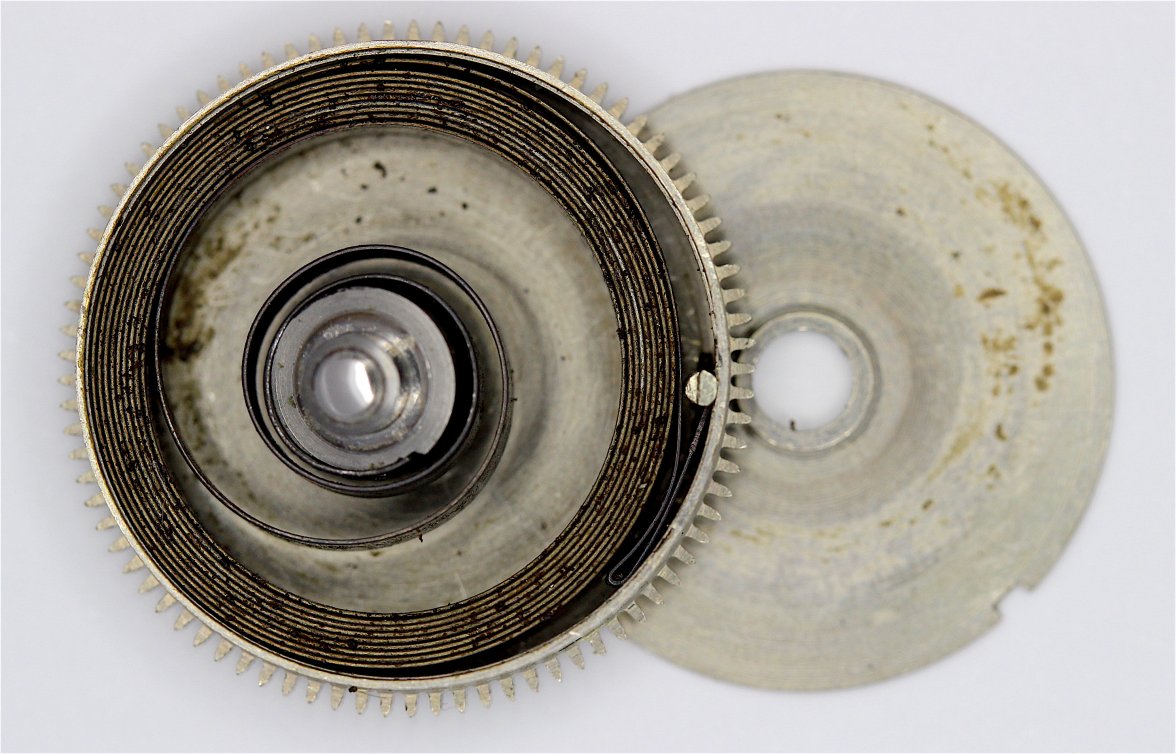

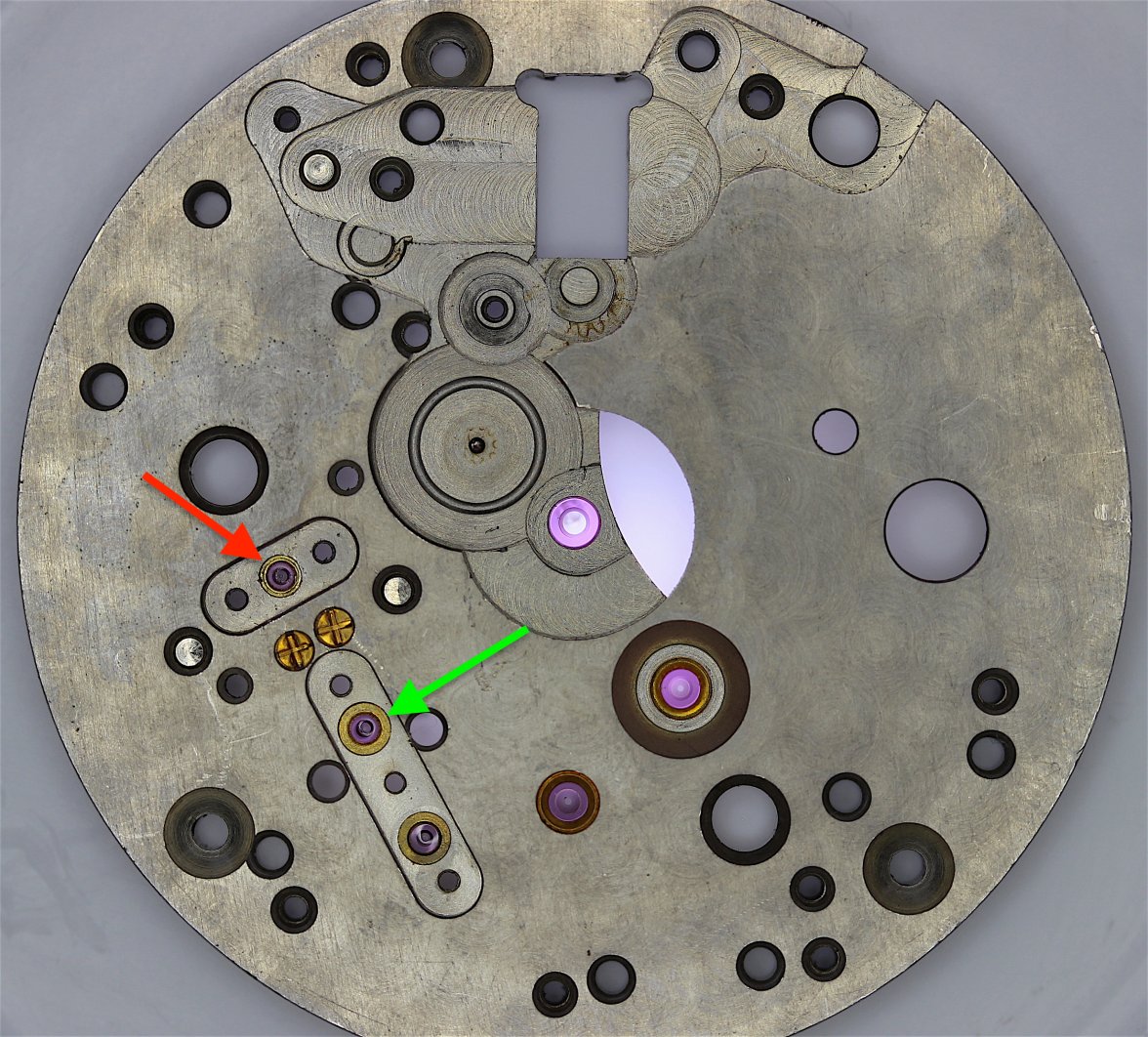

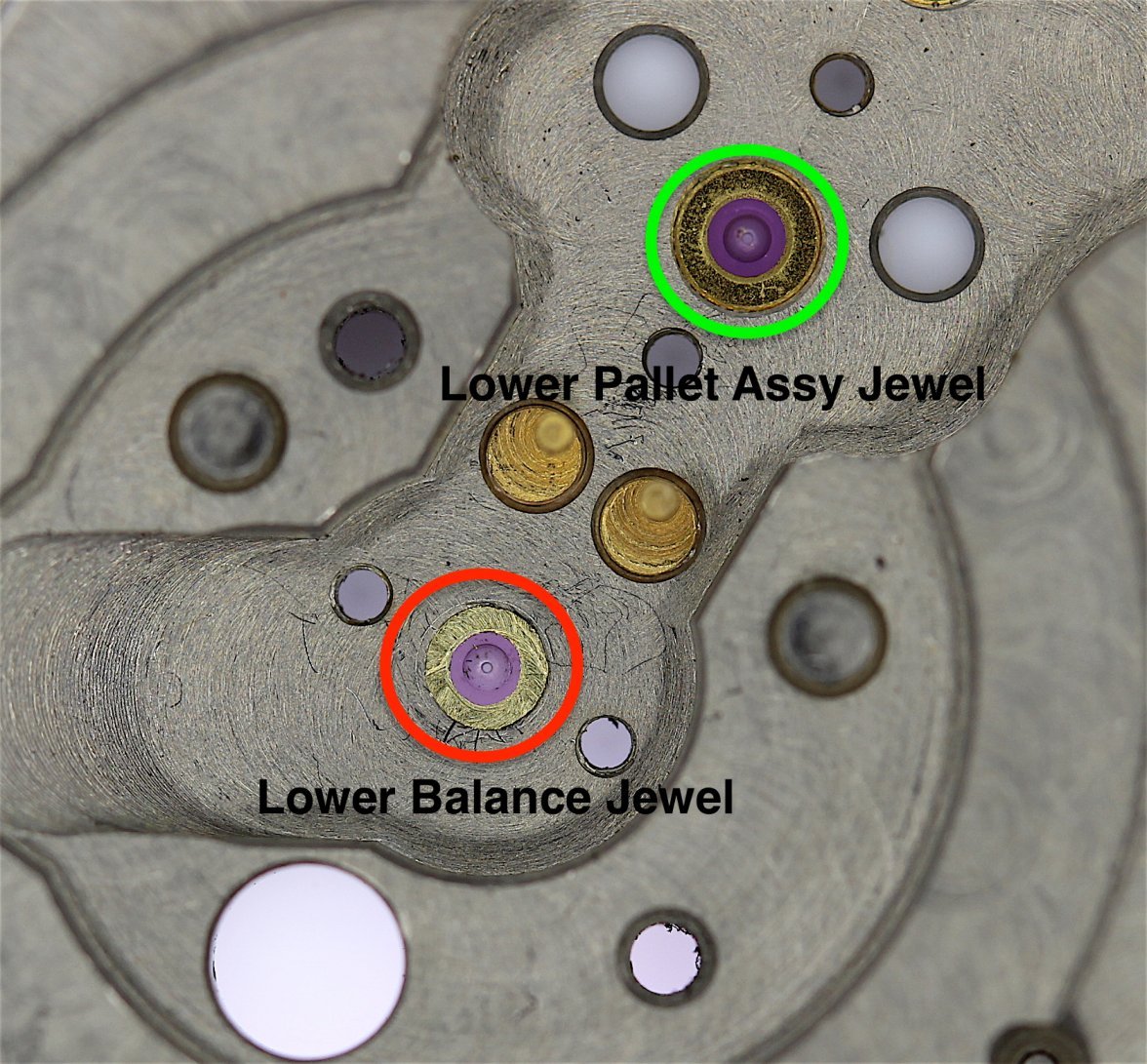

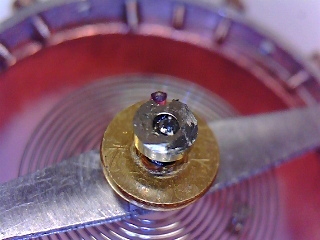

However, after receiving it (as “recently serviced”) and opening it to view the movement, I noticed some large bits of crud in the movement (hard to see here, but they were there).

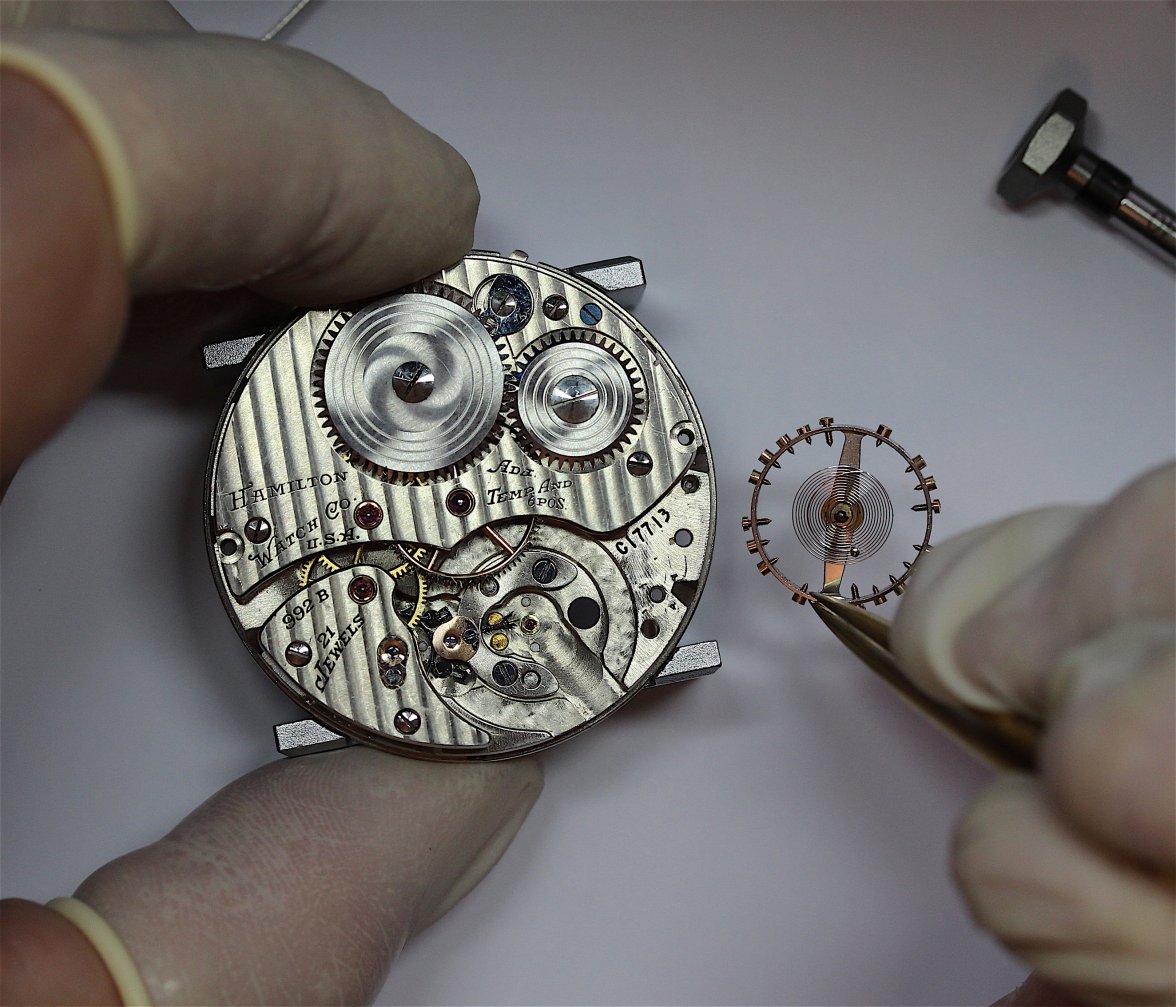

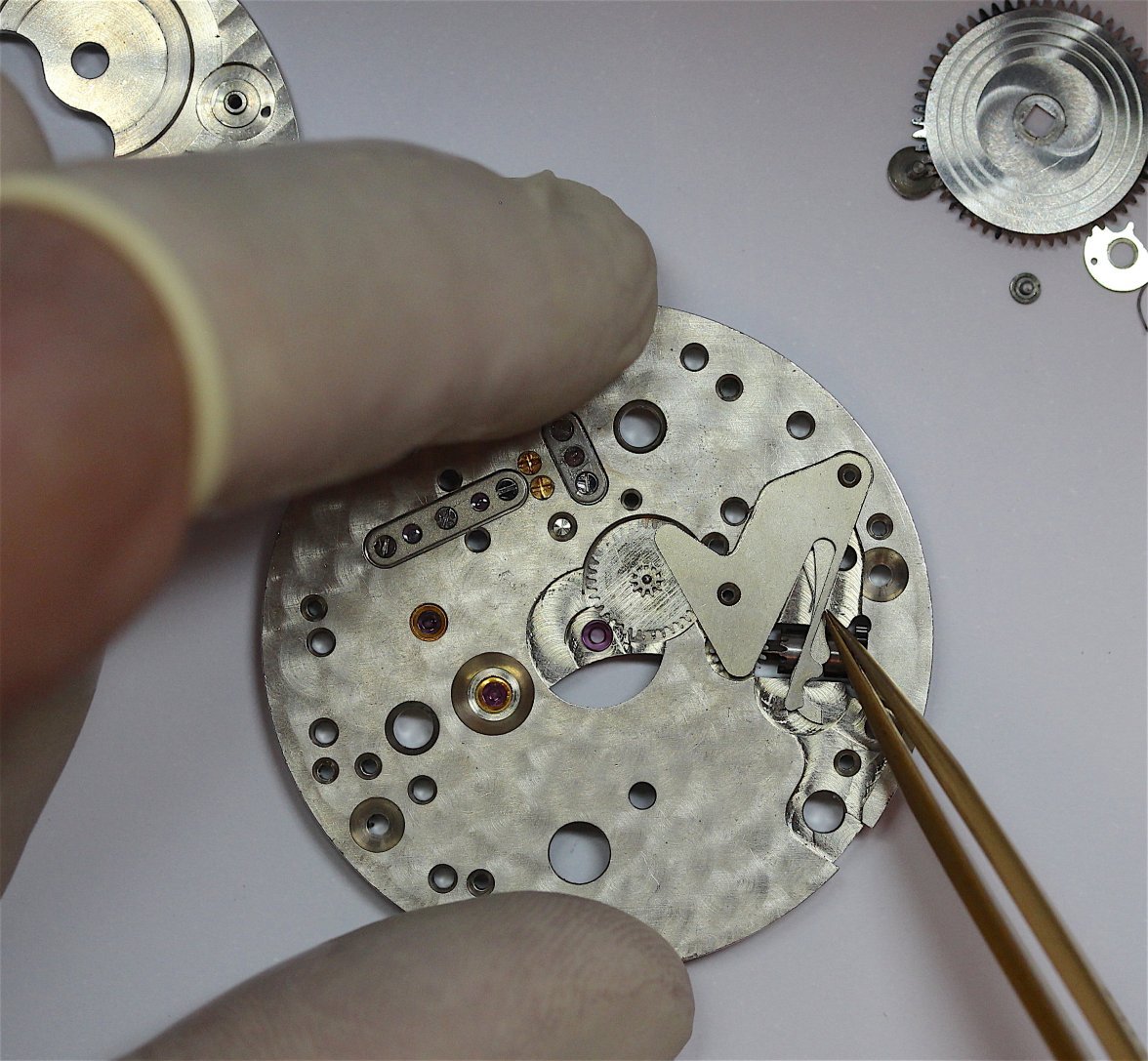

On the Timegrapher it was very erratic so I thought it could do with a service and after my last job (Seiko Chronograph) I thought I deserved something simple. So off to the bench it goes.

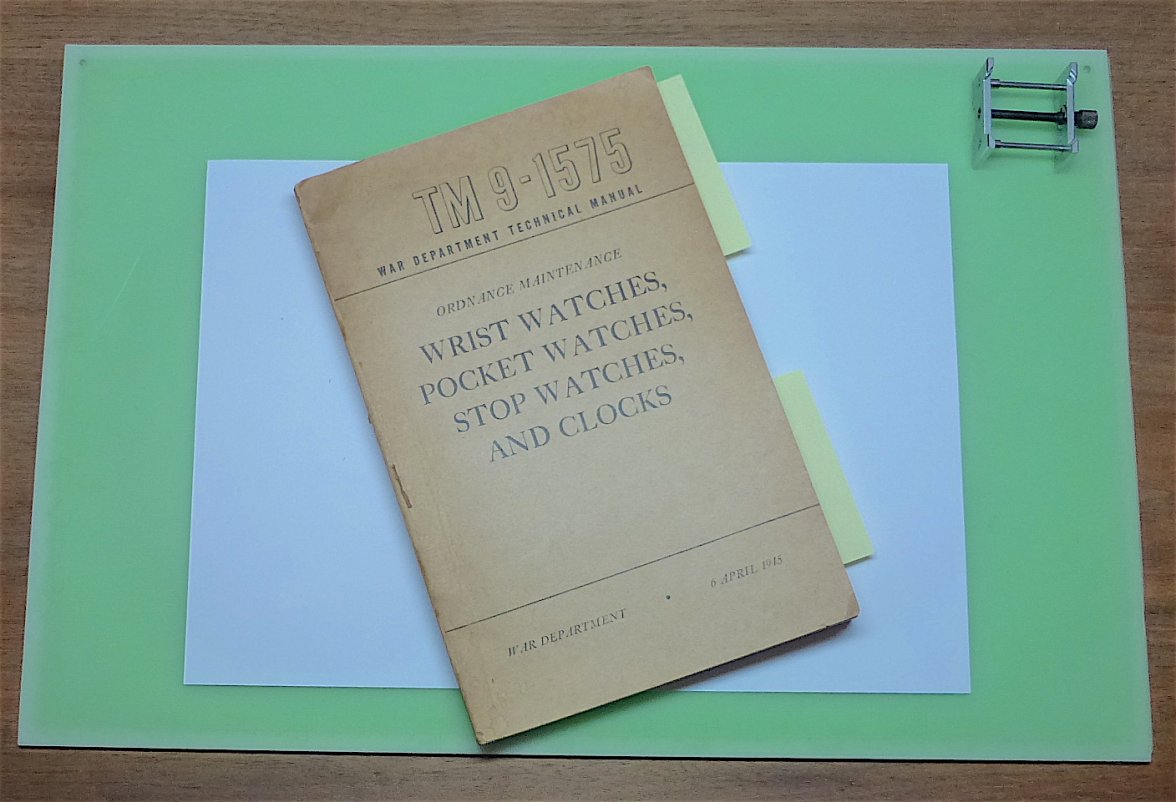

My reference for the service is TM 9-1575, the US Army manual for watch maintenance in the 1940s. My copy is rather fragile to use on the bench so I’ll be using my PDF copy which can be found here.

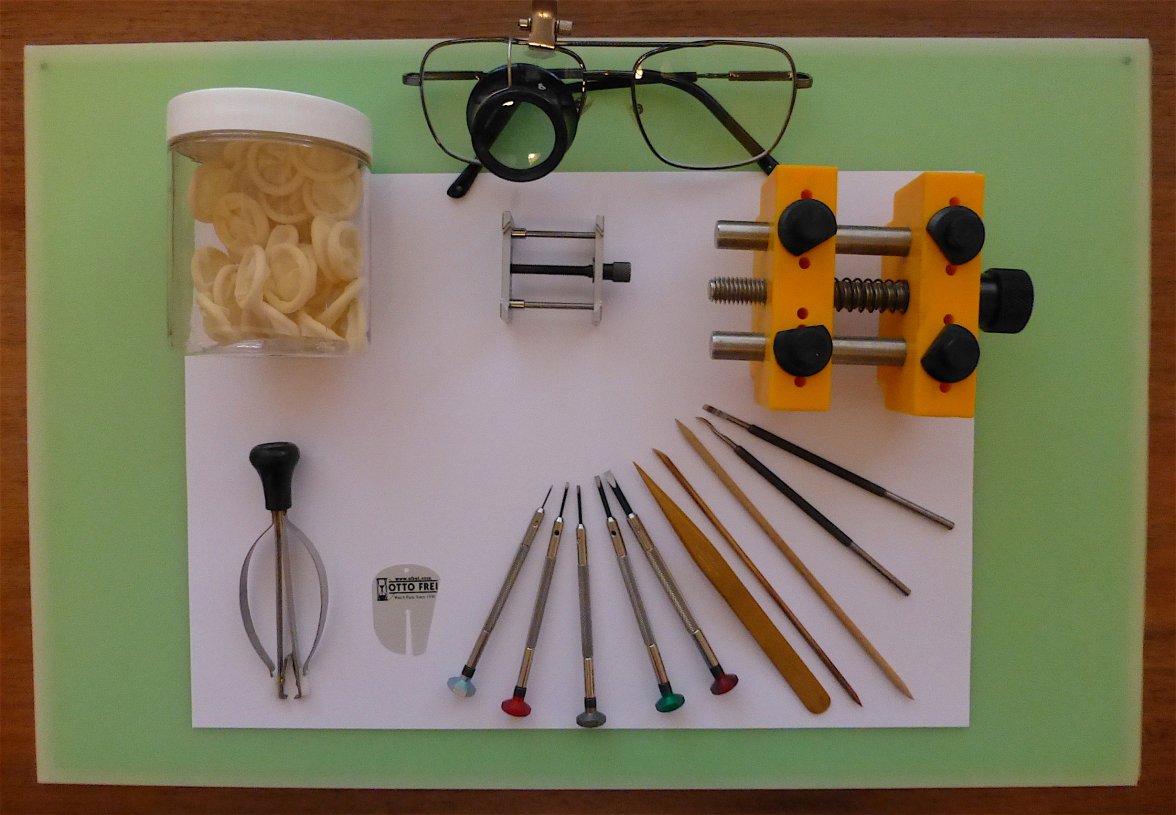

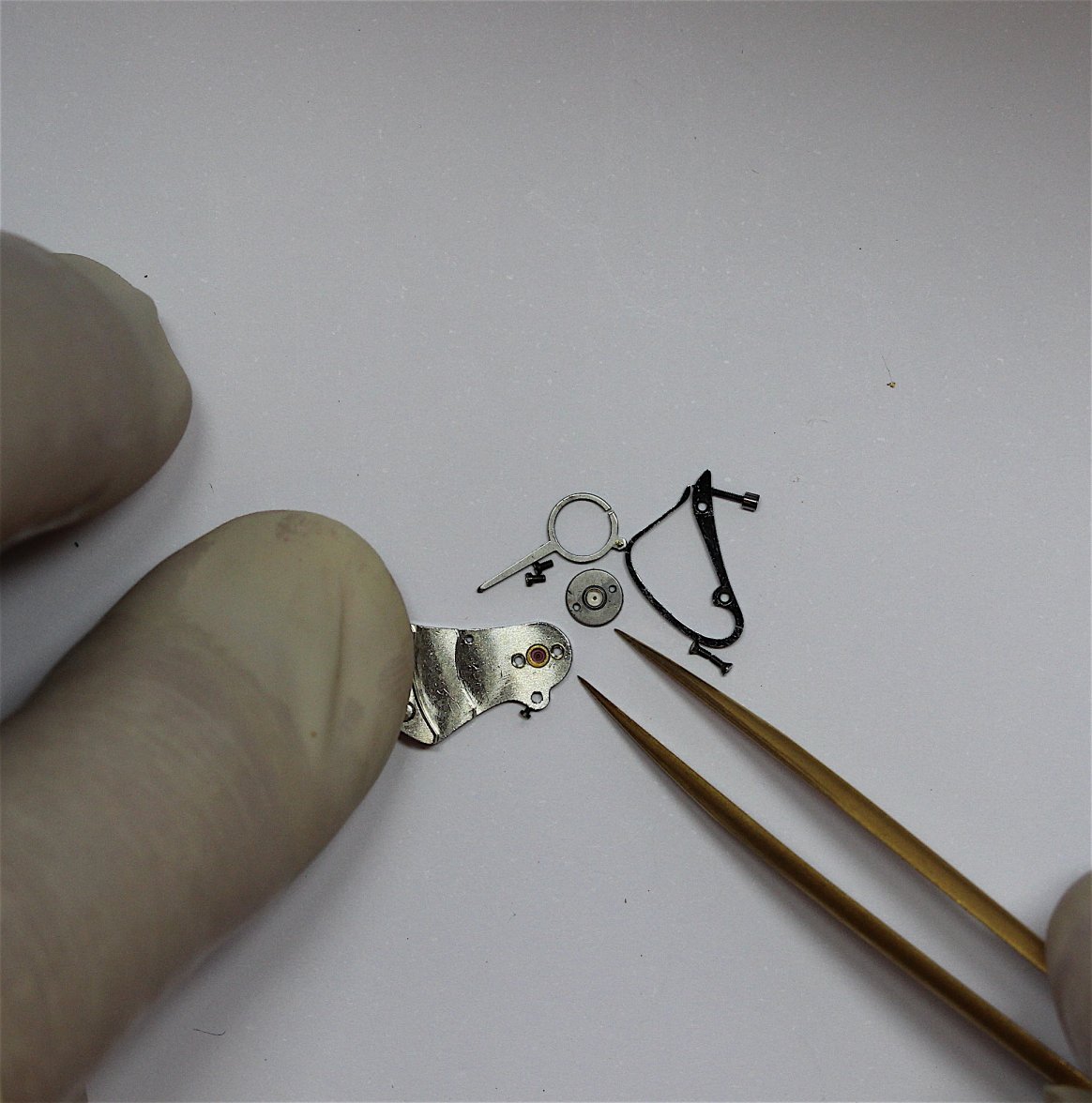

Not many fancy tools required for the task of disassembly, just these will do.

So off we go.

However, after receiving it (as “recently serviced”) and opening it to view the movement, I noticed some large bits of crud in the movement (hard to see here, but they were there).

On the Timegrapher it was very erratic so I thought it could do with a service and after my last job (Seiko Chronograph) I thought I deserved something simple. So off to the bench it goes.

My reference for the service is TM 9-1575, the US Army manual for watch maintenance in the 1940s. My copy is rather fragile to use on the bench so I’ll be using my PDF copy which can be found here.

Not many fancy tools required for the task of disassembly, just these will do.

So off we go.