JimInOz

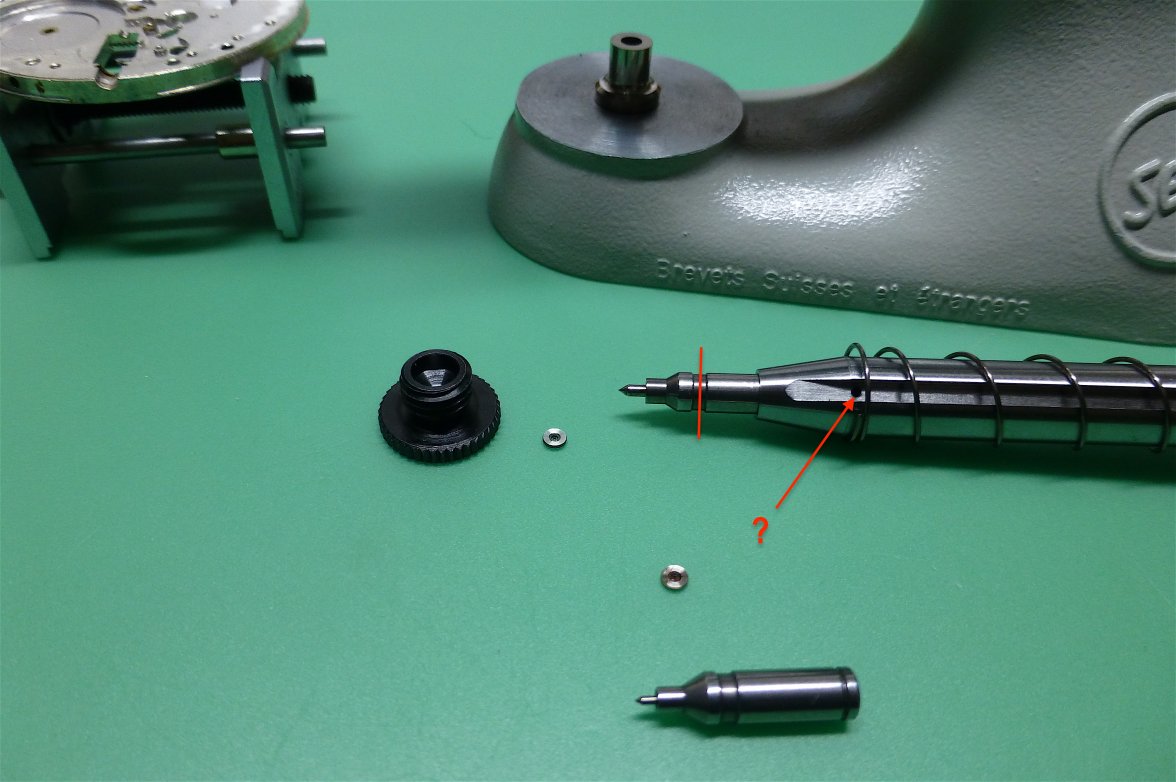

··Melbourne AustraliaI'm removing some broken jewels from a plate and when I went to change pushers the one I'd just used was stuck tight in the spindle and I couldn't pull it out with my finger nails. It was fully in up to the red line.

I had to go to the garage and use alloy soft jaws in my bench vice to get it out.

I assume the hole with the ? is to prevent air from pressurising in the spindle and stopping a vacuum when removing the pusher.

Any secret tips for preventing this or is there a tool that can be used as a pusher extractor that won't mark the pusher or spindle?

I had to go to the garage and use alloy soft jaws in my bench vice to get it out.

I assume the hole with the ? is to prevent air from pressurising in the spindle and stopping a vacuum when removing the pusher.

Any secret tips for preventing this or is there a tool that can be used as a pusher extractor that won't mark the pusher or spindle?