Harry jenkins

·I am not a watch maker. Far from it. This watch came into my possession. Was working fine.

Running great keeping good time for a watch from 1914. Been in drawer for few months.

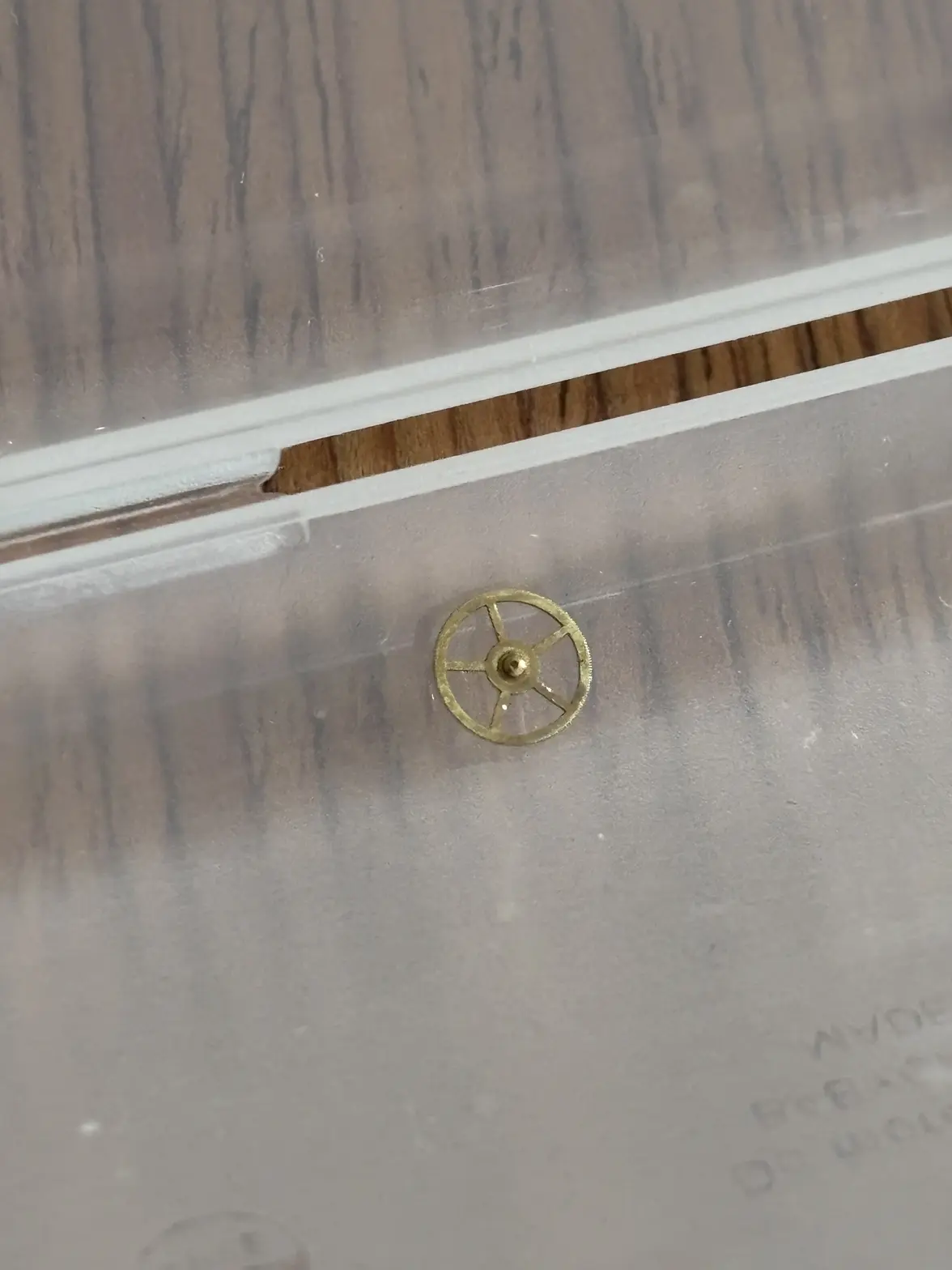

Today I wound it a little, pushed the single pusher, nothing happened. I wound it more because in the past I've noticed that the chronograph dries the power quicker than not engaging it at all. Pushed the chrono pusher. Nothing still. Full wind. Pushed chrono pusher - still nothing. Opened case back. Thought I heard something fall on the ground. Looked on ground - found this:

Here is a picture of the movement when I purchased it.

Here is a picture of the movement now.

Here is where the fallen part belongs. (I hope there are no more fallen parts)

I am asking - how screwed am I? Can I put it back myself? (it has touched human flesh) What damage has been done? Why do you think it fell out?

Many thanks in advance.

Running great keeping good time for a watch from 1914. Been in drawer for few months.

Today I wound it a little, pushed the single pusher, nothing happened. I wound it more because in the past I've noticed that the chronograph dries the power quicker than not engaging it at all. Pushed the chrono pusher. Nothing still. Full wind. Pushed chrono pusher - still nothing. Opened case back. Thought I heard something fall on the ground. Looked on ground - found this:

Here is a picture of the movement when I purchased it.

Here is a picture of the movement now.

Here is where the fallen part belongs. (I hope there are no more fallen parts)

I am asking - how screwed am I? Can I put it back myself? (it has touched human flesh) What damage has been done? Why do you think it fell out?

Many thanks in advance.

Edited: