Archer

··Omega Qualified WatchmakerWondering what complication you own that you find is the most useful?

For me, in the past I would have said the alarm without a doubt. My JLC Master Compressor Memovox was my travel watch for many years, and I would use the alarm function to wake me up in the morning, rather then rely on things like wake up calls (which often didn't happen on time), or the crappy alarm clocks in hotel rooms.

Plenty loud enough to wake me up:

It could also be used for reminders during the day, so overall a great complication.

I don't travel for business nearly as much as I used to, so with the work I do now, the complication I find most useful is the chronograph. It's the main reason why I wear my Speedmaster most days, and when I don't have it on, I do miss it for work. When servicing a watch there are several things that require timing, such as the length of time that specific parts are being treated with elpiame:

It's also used to time the drying of the parts after, and the same goes for treating reversing wheels with V105 and timing how long they must dry for:

When I'm performing high pressure wet testing, the first stages are done without the movement in the case, and during these tests the chronograph works well to time the various stages of the testing:

The one that the chronograph works very well for is the damping test. This is a test of the condition and cleanliness of the ball bearing on the oscillating weight of an automatic watch. The test is done by mounting the weight on peg wood, and supporting it so it can swing - I use two movement holders for this. The weight is moved to a position that is 90 degrees from the hanging position, and when I let it go with one hand, I press the start button on the chronograph with the other:

The weight is left to swing until it stops, and at the end the oscillations are very small - you observe them with a loupe:

When the oscillations stop, I press the stop button and check the duration of the swinging:

The time that is acceptable varies depending on the weight. In this case the minimum required is 45 seconds, and here I have 58, so it's good. The bearing is then oiled, and the test is repeated, and the duration of the swinging should not drop more than 5 seconds, and in any case must still be above 45.

So for me personally, this is a complication I use daily in my work, and is by far the most useful.

How about everyone else?

Cheers, Al

For me, in the past I would have said the alarm without a doubt. My JLC Master Compressor Memovox was my travel watch for many years, and I would use the alarm function to wake me up in the morning, rather then rely on things like wake up calls (which often didn't happen on time), or the crappy alarm clocks in hotel rooms.

Plenty loud enough to wake me up:

It could also be used for reminders during the day, so overall a great complication.

I don't travel for business nearly as much as I used to, so with the work I do now, the complication I find most useful is the chronograph. It's the main reason why I wear my Speedmaster most days, and when I don't have it on, I do miss it for work. When servicing a watch there are several things that require timing, such as the length of time that specific parts are being treated with elpiame:

It's also used to time the drying of the parts after, and the same goes for treating reversing wheels with V105 and timing how long they must dry for:

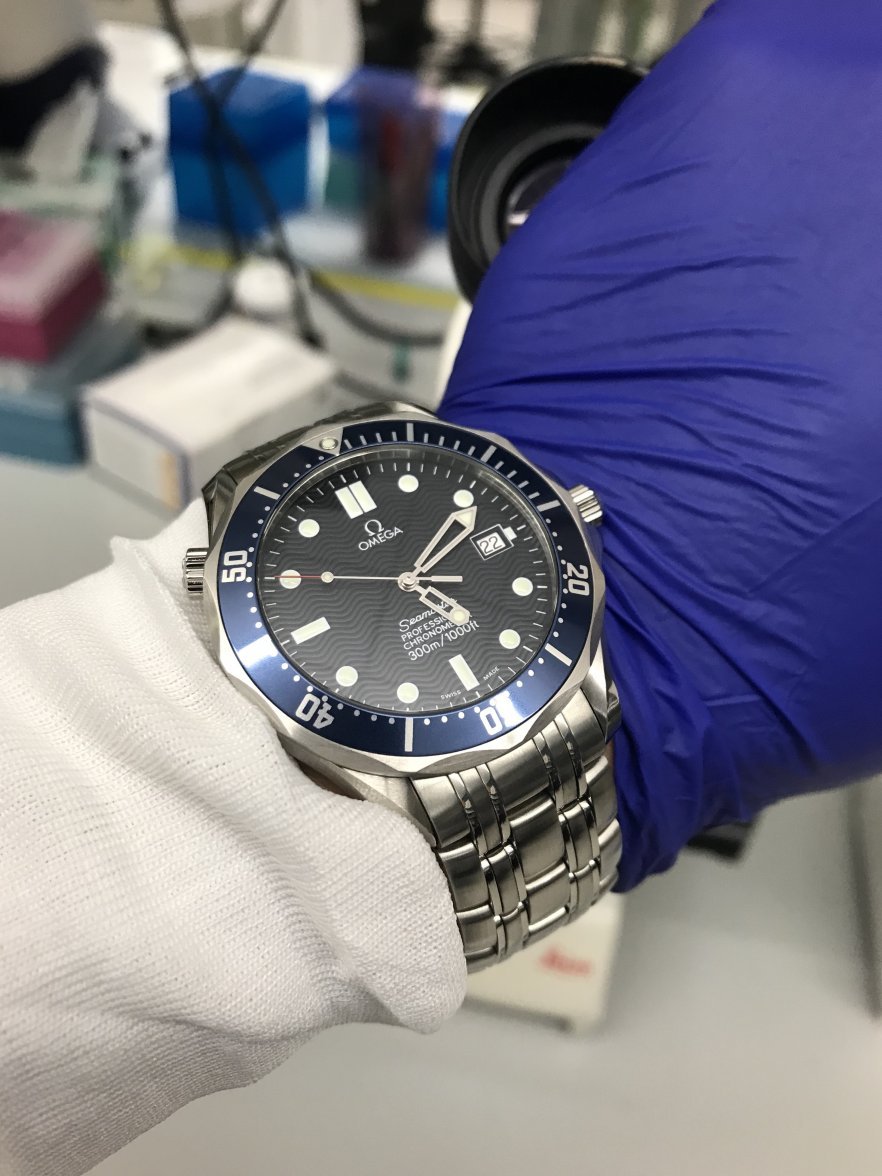

When I'm performing high pressure wet testing, the first stages are done without the movement in the case, and during these tests the chronograph works well to time the various stages of the testing:

The one that the chronograph works very well for is the damping test. This is a test of the condition and cleanliness of the ball bearing on the oscillating weight of an automatic watch. The test is done by mounting the weight on peg wood, and supporting it so it can swing - I use two movement holders for this. The weight is moved to a position that is 90 degrees from the hanging position, and when I let it go with one hand, I press the start button on the chronograph with the other:

The weight is left to swing until it stops, and at the end the oscillations are very small - you observe them with a loupe:

When the oscillations stop, I press the stop button and check the duration of the swinging:

The time that is acceptable varies depending on the weight. In this case the minimum required is 45 seconds, and here I have 58, so it's good. The bearing is then oiled, and the test is repeated, and the duration of the swinging should not drop more than 5 seconds, and in any case must still be above 45.

So for me personally, this is a complication I use daily in my work, and is by far the most useful.

How about everyone else?

Cheers, Al