JimInOz

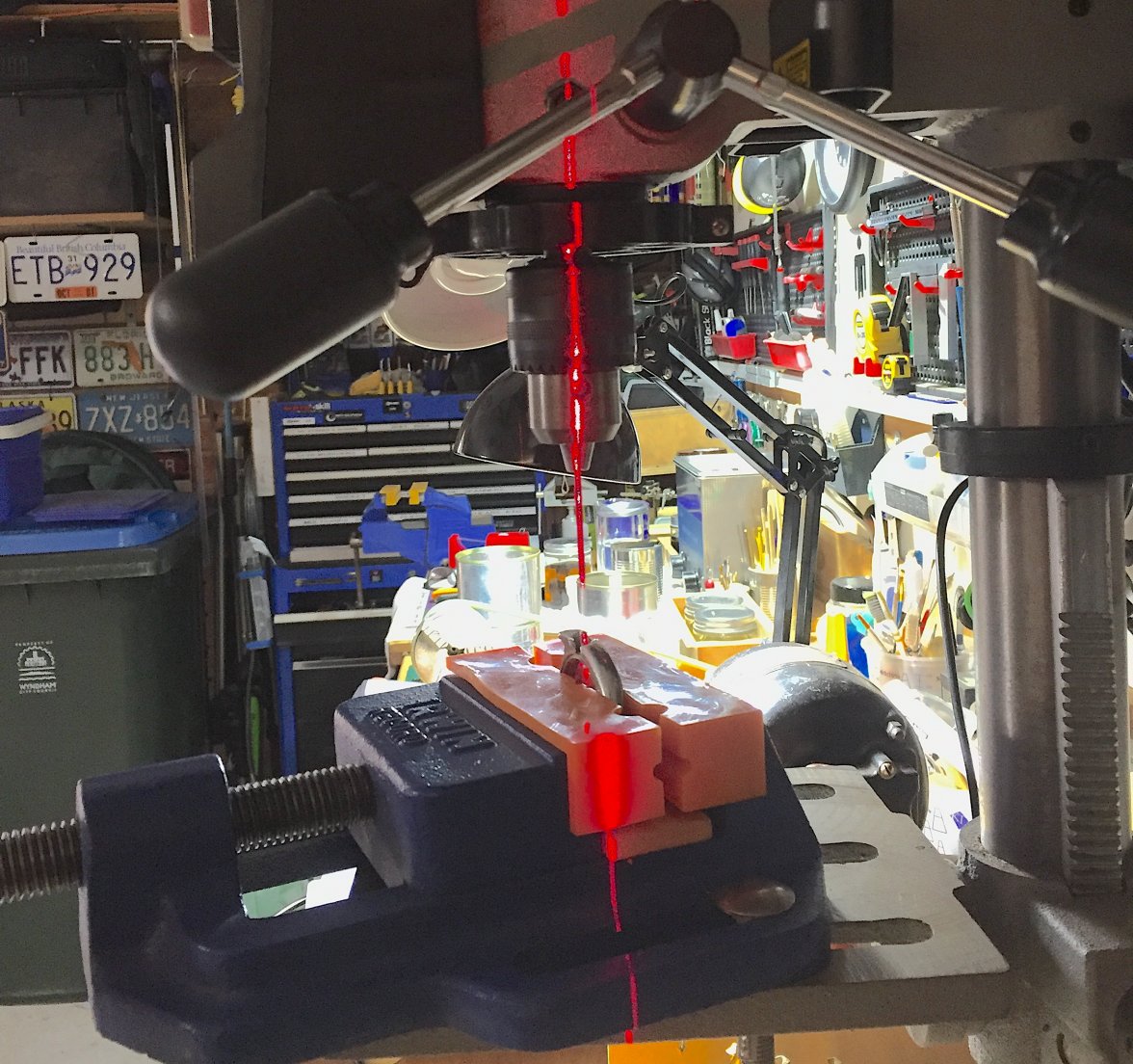

··Melbourne Australia................. to drill the stem tube out.

But it takes much longer to get everything correctly aligned and bolted down on my "hobby quality" drill press.

First we do a rough alignment using a 1.99mm ø blued steel pivot wire in place of a drill bit to get the case in position.

Next comes a test to check alignment at three positions.

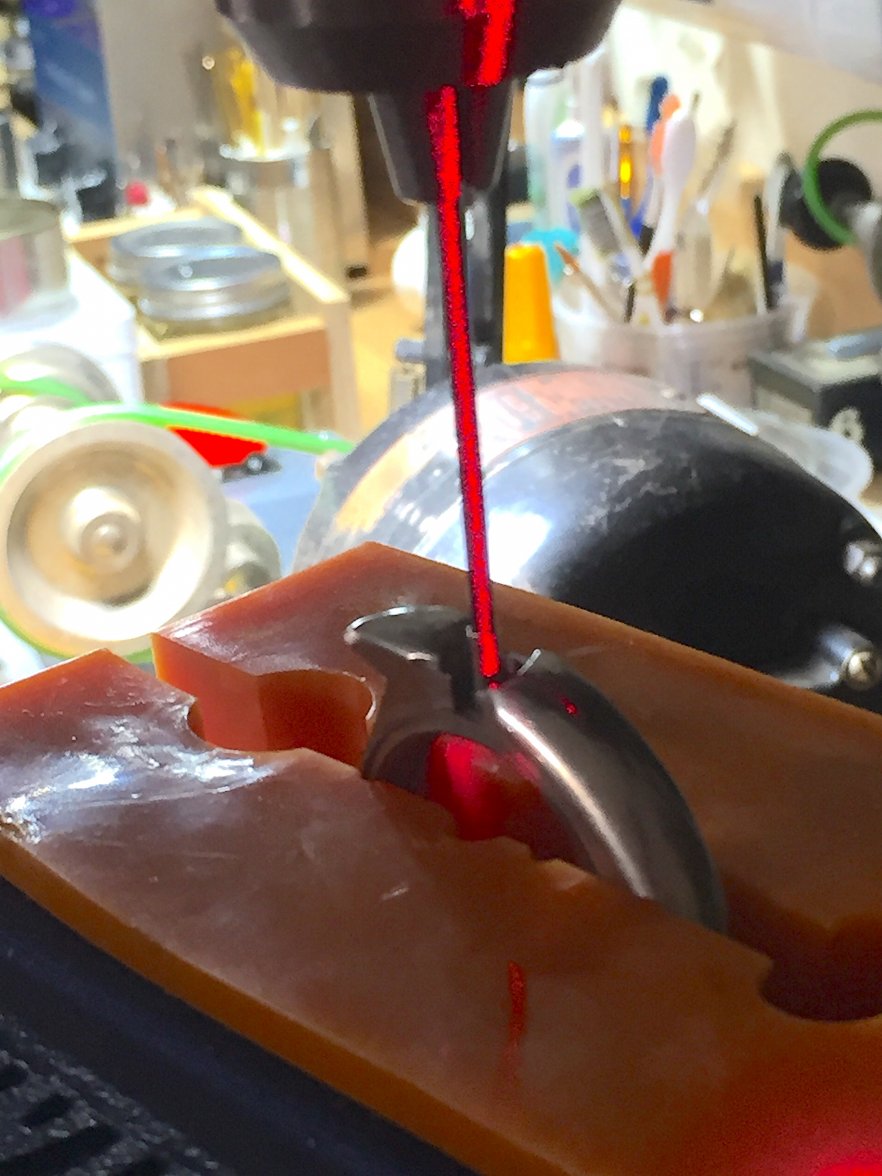

With minute adjustments made to the drilling vice (taps with a dead blow mallet), a final "feel check" is done to check centricity (is that a word?).

And with all of the rigmarole complete, it's the easiest part (most heart bumping part!).

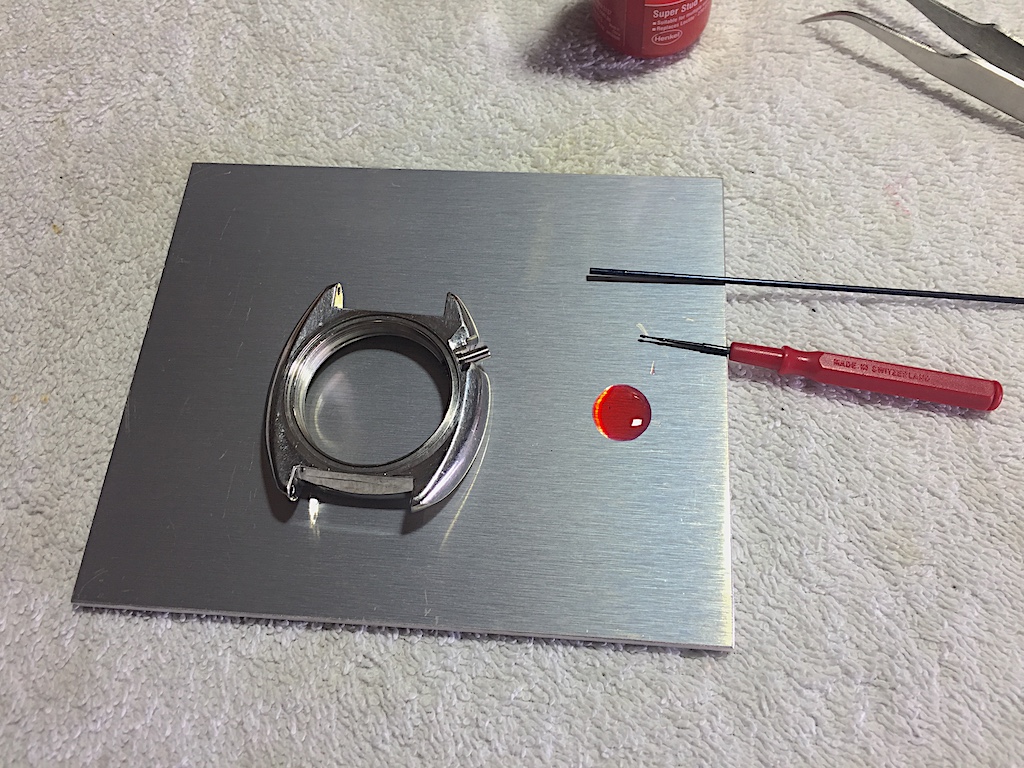

Drilling out the tube with a 2.97mm ø drill.

After that, I need a beer, so more next time.

But it takes much longer to get everything correctly aligned and bolted down on my "hobby quality" drill press.

First we do a rough alignment using a 1.99mm ø blued steel pivot wire in place of a drill bit to get the case in position.

Next comes a test to check alignment at three positions.

With minute adjustments made to the drilling vice (taps with a dead blow mallet), a final "feel check" is done to check centricity (is that a word?).

And with all of the rigmarole complete, it's the easiest part (most heart bumping part!).

Drilling out the tube with a 2.97mm ø drill.

After that, I need a beer, so more next time.