pdxleaf

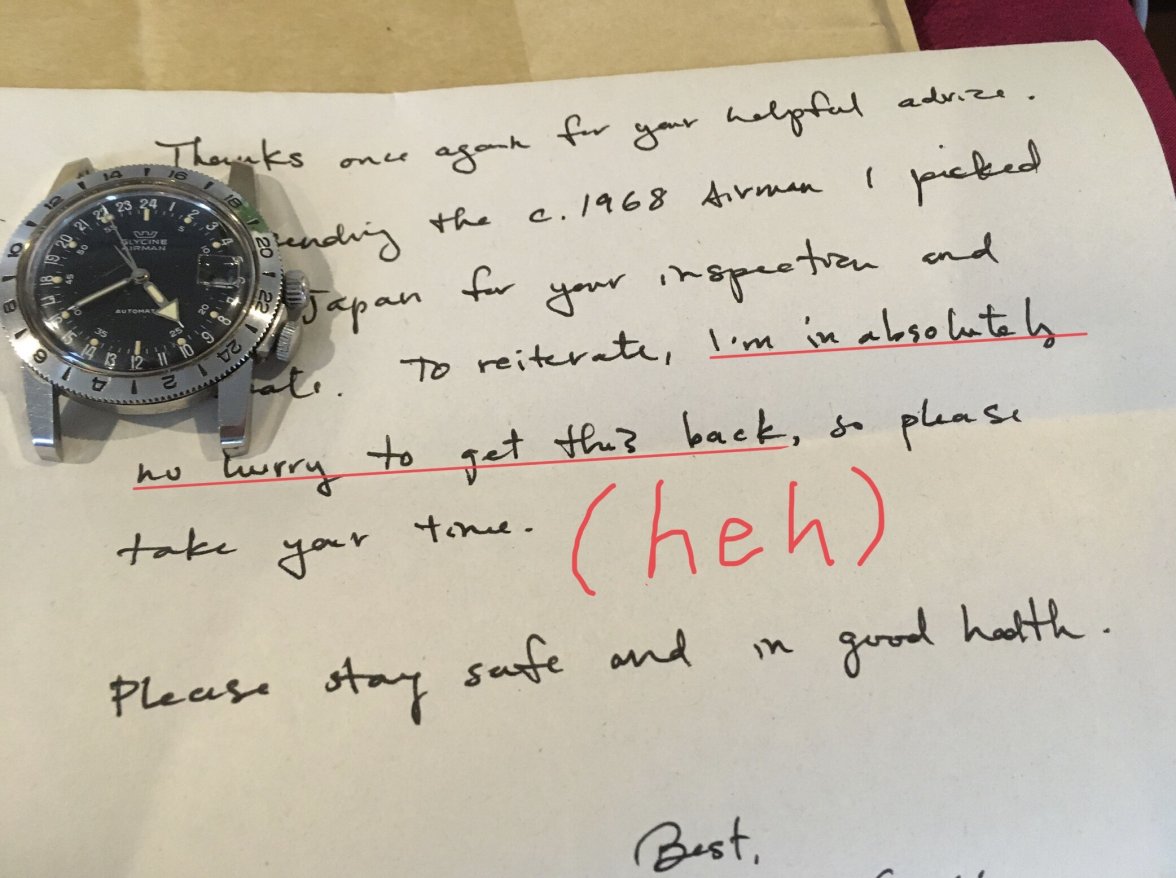

·While servicing my Glycine Airman, Jim at Nevada watch repair found a problem. His explanation to me of the problem and its cause was so thorough and educational that it seemed like something others would also enjoy. So with his permission, here is his explanation for the problem with my watch, which also explains how the watch would normally function.

Again, thanks to Jim for both the excellent description and for being kind enough to allow me to share it.

‐‐----------------

Wed 6/30/2021 3:54 PM

Dave,

While working on your watch I made a troubling discovery. The minute wheel post has been broken at some point in the past and improperly repaired. This is the sort of thing one only finds when doing a complete disassembly. I was aware of your observation that the watch was losing large amounts of time. Usually, this is because of a loose cannon pinion. The cannon pinion on your watch was very loose, but there was more.

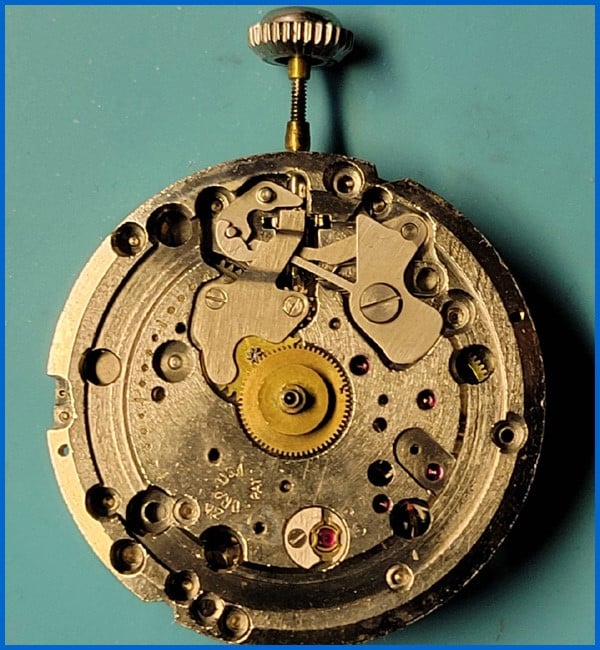

I have some photographs and will attempt to explain the situation. The first image is of the movement with the dial and calendar parts removed.

The brass gear in the center is the hour wheel (in watches, what would normally be described as gears are called wheels. With the invention of watches dating back to the sixteenth century, there is probably some archaic reason for the term "wheels". The hour wheel is the part that carries the hour hand. On the upper left, you will see there is a very small pinion that turns the hour wheel.

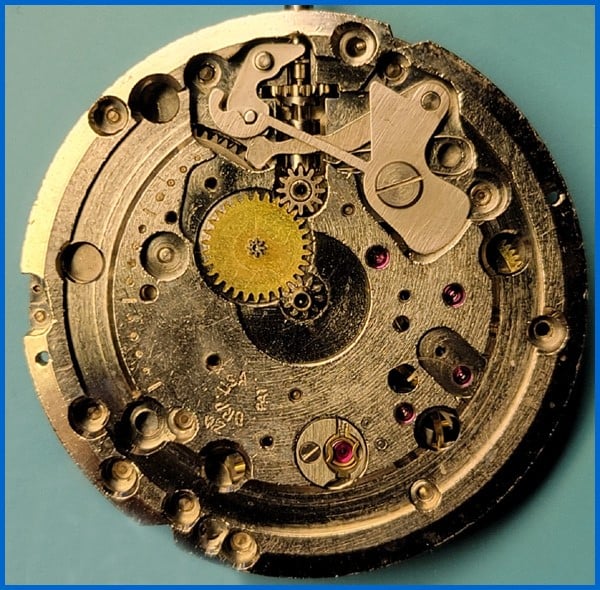

With the hour wheel removed, that pinion for turning the hour wheel is part of the minute wheel. The pinion is very small, in order to get the correct gear ratio so that the hour wheel only turns once a day, rather than twice a day as in a watch with a twelve-hour dial.

The minute wheel is turned by the cannon pinion, which is the steel part in the center of the movement. The cannon pinion fits over the center wheel arbor and is a sufficiently tight fit that when the center wheel turns, the cannon pinion turns with it, driving the minute and the hour wheels as well as the date disc.

In order to set the watch, one must be able to turn the cannon pinion, which is why it is driven by friction. It is tight enough to turn the hands without slipping, but not so tight that it won't slip when setting the hands. You can see the setting wheel in the upper center. With the stem in the setting position, turning the stem turns the setting wheel which turns the minute wheel and the cannon pinion.

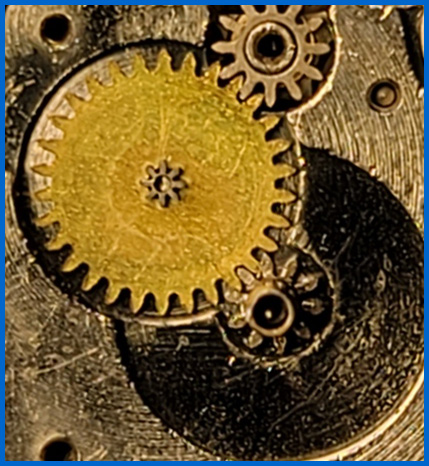

There is a hole in the center of the minute wheel, and the minute wheel turns on a post, the minute wheel post, which is a part of the movement plate. Because the pinion is so small, the minute wheel post needs to be very small as well and consequently not particularly robust.

The friction of the cannon pinion is adjustable by a dent in the tubular portion of the cannon pinion. This can be a delicate adjustment--tight enough to turn the hands, not so tight as to stress the setting parts.

Sometime in the past, either a previous repairer over tightened the cannon pinion, or the cannon pinion became seized from lack of lubrication, and in the operation of setting the hands, the minute wheel post was broken. The minute wheel post was subsequently replaced by a previous repairer, but the post is slightly off-center from its original location. The result is that the mesh between the gear teeth on the minute wheel and the gear teeth on the cannon pinion has no clearance. In the closeup image below compare the clearance with the setting wheel with the clearance to the cannon pinion. The teeth can butt and stop the watch. I am suspecting that the person who replaced the minute wheel post deliberately loosened the cannon pinion friction in an obviously unsuccessful attempt to overcome the off-center condition.

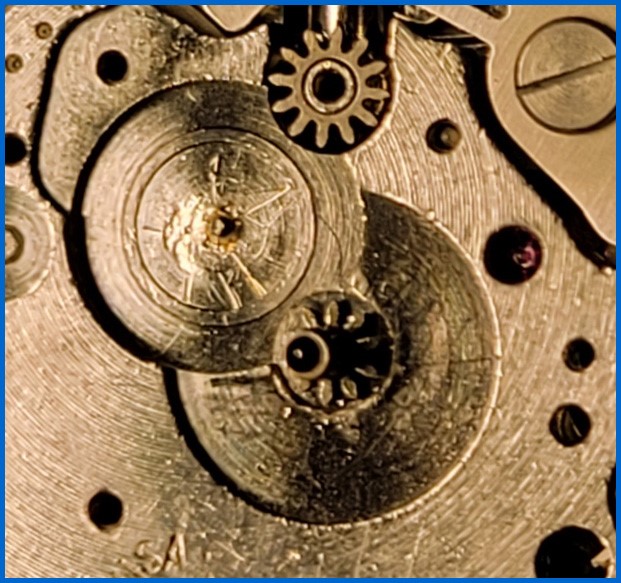

In this image, and in the closeup below, you can see the evidence of an unskillful attempt to replace the broken minute wheel post.

This watch, in its present condition, will not be reliable. I cannot service the watch and offer a one-year warranty because there is a very strong likelihood that you will be sending the watch back to me. The minute wheel post can be correctly repaired/replaced.

However, it is costly and takes much time. I do not do this work myself. I have a colleague who is equipped with the sort of precision equipment required to precisely locate the post where it should be. The cost to do this is $475.00 and may take two months or longer. Considering the other issues with the watch, you may wish to consider the economic viability of restoring the watch to good running condition.

It is disappointing to me to be the bearer of bad news and surely this is disappointing to you as well.

Kind regards,

Jim

James Sadilek, Carson City, NVwww.nevadawatchrepair.com

Glycine Heritage Agent for the U.S.

Free Watch Parts Search Website -- www.ccwatchmaker.com

Co-owner/Moderator of Horology Matters Groups.io

‐----‐---------------

Postscript

If you made it this far you may wonder what has happened next. Jim will get the post fixed and continue with the service. It adds time and money but hey, it's only time and money compared to saving a watch.

Also, the shadows in the photo make the plate appear rusty and pitted, but Jim says it isn't. In case anyone wonders.

Hope all you budding watchmakers enjoyed this as much as I did, not to mention gained an even greater appreciation for the skill and knowledge of watchmakers.

Cheers

Again, thanks to Jim for both the excellent description and for being kind enough to allow me to share it.

‐‐----------------

Wed 6/30/2021 3:54 PM

Dave,

While working on your watch I made a troubling discovery. The minute wheel post has been broken at some point in the past and improperly repaired. This is the sort of thing one only finds when doing a complete disassembly. I was aware of your observation that the watch was losing large amounts of time. Usually, this is because of a loose cannon pinion. The cannon pinion on your watch was very loose, but there was more.

I have some photographs and will attempt to explain the situation. The first image is of the movement with the dial and calendar parts removed.

The brass gear in the center is the hour wheel (in watches, what would normally be described as gears are called wheels. With the invention of watches dating back to the sixteenth century, there is probably some archaic reason for the term "wheels". The hour wheel is the part that carries the hour hand. On the upper left, you will see there is a very small pinion that turns the hour wheel.

With the hour wheel removed, that pinion for turning the hour wheel is part of the minute wheel. The pinion is very small, in order to get the correct gear ratio so that the hour wheel only turns once a day, rather than twice a day as in a watch with a twelve-hour dial.

The minute wheel is turned by the cannon pinion, which is the steel part in the center of the movement. The cannon pinion fits over the center wheel arbor and is a sufficiently tight fit that when the center wheel turns, the cannon pinion turns with it, driving the minute and the hour wheels as well as the date disc.

In order to set the watch, one must be able to turn the cannon pinion, which is why it is driven by friction. It is tight enough to turn the hands without slipping, but not so tight that it won't slip when setting the hands. You can see the setting wheel in the upper center. With the stem in the setting position, turning the stem turns the setting wheel which turns the minute wheel and the cannon pinion.

There is a hole in the center of the minute wheel, and the minute wheel turns on a post, the minute wheel post, which is a part of the movement plate. Because the pinion is so small, the minute wheel post needs to be very small as well and consequently not particularly robust.

The friction of the cannon pinion is adjustable by a dent in the tubular portion of the cannon pinion. This can be a delicate adjustment--tight enough to turn the hands, not so tight as to stress the setting parts.

Sometime in the past, either a previous repairer over tightened the cannon pinion, or the cannon pinion became seized from lack of lubrication, and in the operation of setting the hands, the minute wheel post was broken. The minute wheel post was subsequently replaced by a previous repairer, but the post is slightly off-center from its original location. The result is that the mesh between the gear teeth on the minute wheel and the gear teeth on the cannon pinion has no clearance. In the closeup image below compare the clearance with the setting wheel with the clearance to the cannon pinion. The teeth can butt and stop the watch. I am suspecting that the person who replaced the minute wheel post deliberately loosened the cannon pinion friction in an obviously unsuccessful attempt to overcome the off-center condition.

In this image, and in the closeup below, you can see the evidence of an unskillful attempt to replace the broken minute wheel post.

This watch, in its present condition, will not be reliable. I cannot service the watch and offer a one-year warranty because there is a very strong likelihood that you will be sending the watch back to me. The minute wheel post can be correctly repaired/replaced.

However, it is costly and takes much time. I do not do this work myself. I have a colleague who is equipped with the sort of precision equipment required to precisely locate the post where it should be. The cost to do this is $475.00 and may take two months or longer. Considering the other issues with the watch, you may wish to consider the economic viability of restoring the watch to good running condition.

It is disappointing to me to be the bearer of bad news and surely this is disappointing to you as well.

Kind regards,

Jim

James Sadilek, Carson City, NVwww.nevadawatchrepair.com

Glycine Heritage Agent for the U.S.

Free Watch Parts Search Website -- www.ccwatchmaker.com

Co-owner/Moderator of Horology Matters Groups.io

‐----‐---------------

Postscript

If you made it this far you may wonder what has happened next. Jim will get the post fixed and continue with the service. It adds time and money but hey, it's only time and money compared to saving a watch.

Also, the shadows in the photo make the plate appear rusty and pitted, but Jim says it isn't. In case anyone wonders.

Hope all you budding watchmakers enjoyed this as much as I did, not to mention gained an even greater appreciation for the skill and knowledge of watchmakers.

Cheers

Edited: