GuiltyGear

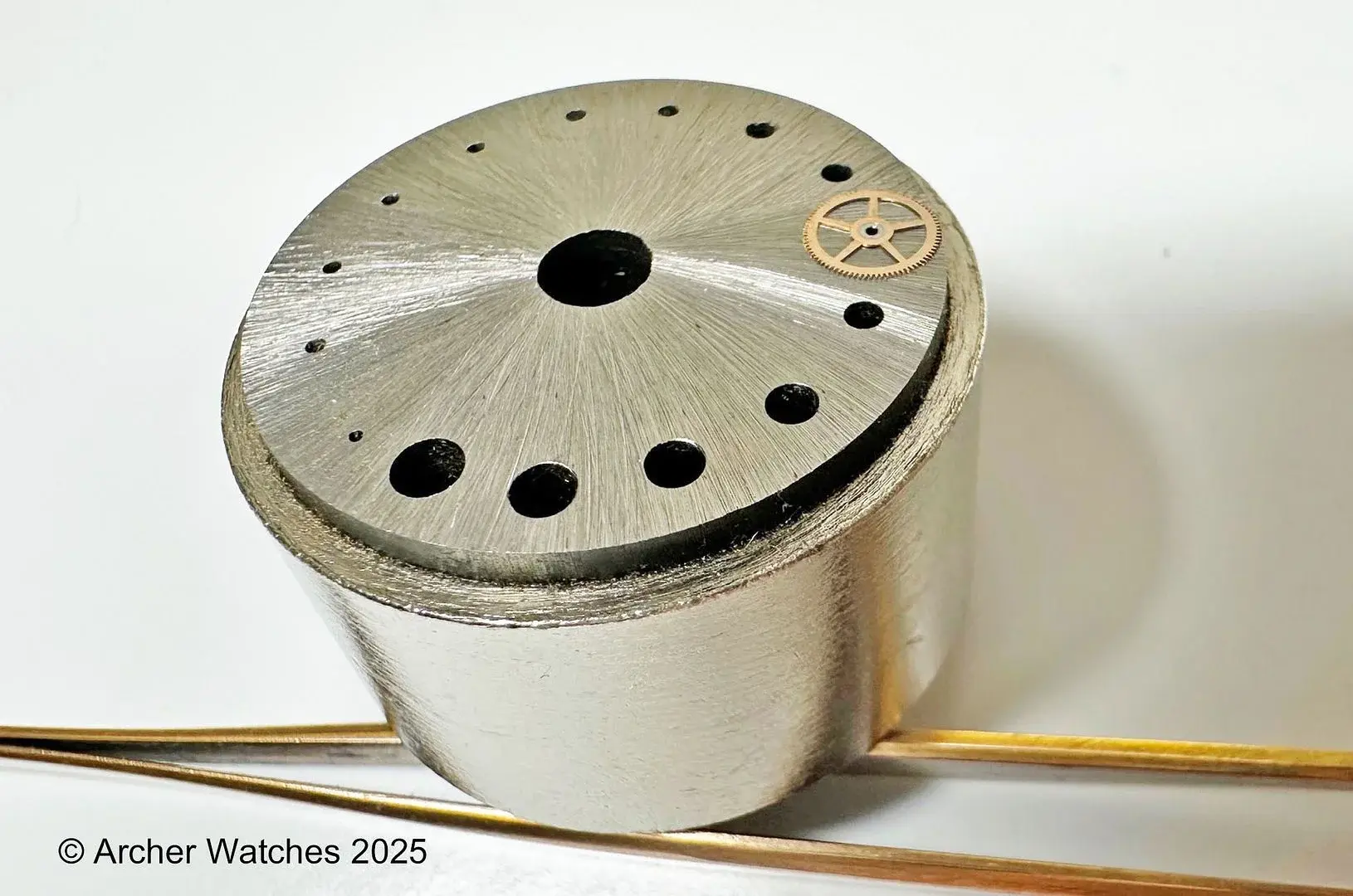

·Hi all. I'm trying to diagnose a problem with the day advance in a Seamaster Cosmic 2000, cal. 1022. The date advances without issue, both quickset (crown in first position) and every 24 hours. The day does advance in quickset (crown in second position, rotate crown away), but not every 24 hours. Most often it will advance partially, sometimes completely, and sometimes not at all.

This is a caliber that's much more than I can chew, but I'm giving it a try. The day star driver, date cam, and jumper lever are all plastic. There's no issue that I can tell with the date cam and lever though, since it advances and snaps correctly. The day star driver does look like a different design from what I'm seeing online, and it may as well be a replacement that doesn't properly catch on the day wheel teeth.

Any ideas would help.

This is a caliber that's much more than I can chew, but I'm giving it a try. The day star driver, date cam, and jumper lever are all plastic. There's no issue that I can tell with the date cam and lever though, since it advances and snaps correctly. The day star driver does look like a different design from what I'm seeing online, and it may as well be a replacement that doesn't properly catch on the day wheel teeth.

Any ideas would help.