Thought I’d modify this thread as the Chronostop is the first Omega chronograph I’ve worked on. It is just about the simplest as well with just a central second hand register (no minute or hour totalisers). I’m an amateur and am working through some simple chronograph services to build up to a 3 register caliber. It was oily and dirty but cleaned up nicely so here are some pictures:

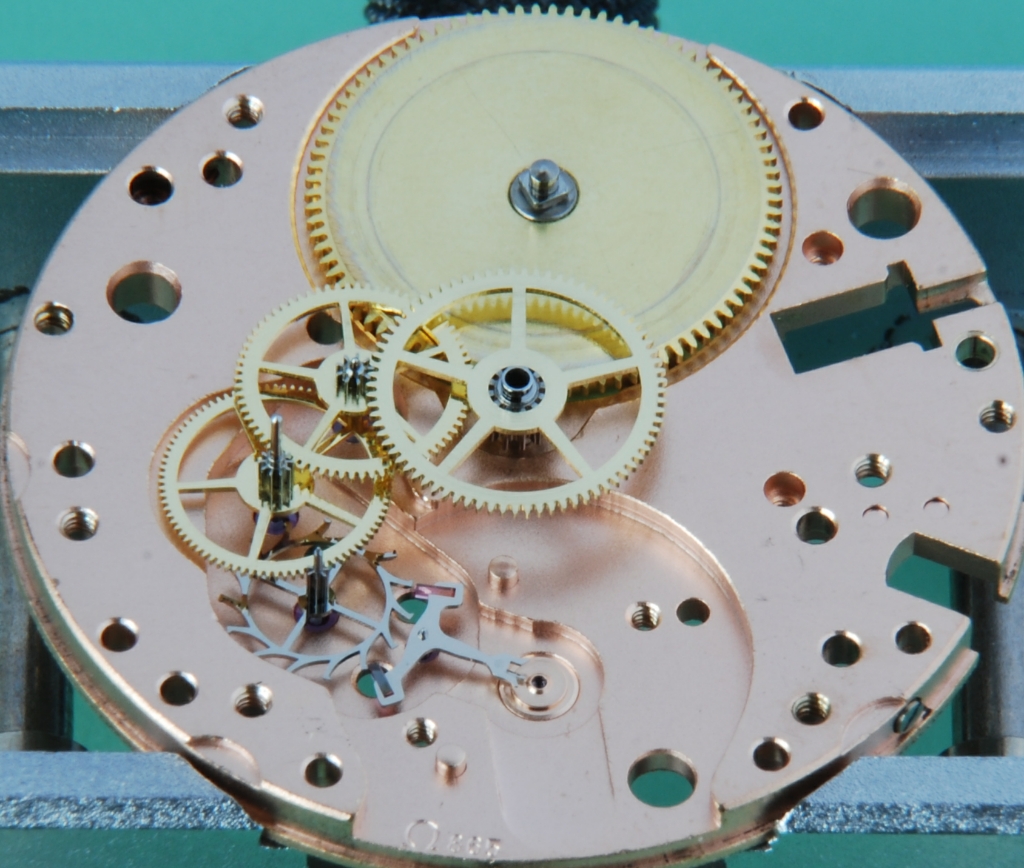

Here is the gear train for an 861/865/1861 looking from the back of the watch just placed in position. You can see the long staff on the fourth wheel which will come through the bridge to power the chronograph part.

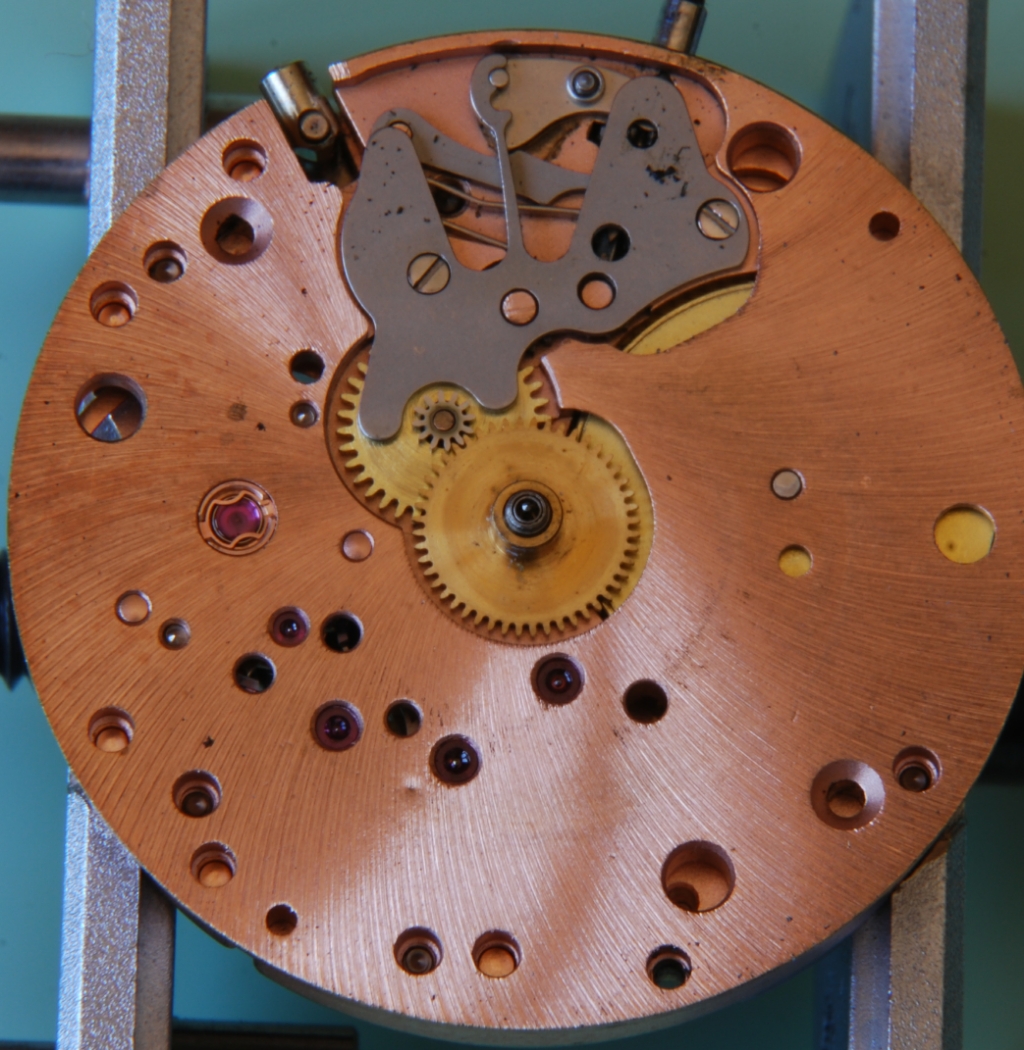

Here with bridges and cocks mounted and the fourth wheel staff can be seen on this side of the big bridge. This is just a basic watch movement, there is no chronograph part here and it is very similar to many other mechanical watches. It’s quite a clean movement but there is some marking of the big bridge where the chronograph parts have rubbed and some damage to the screw heads. I thought this was better preserved but looking back to when I bought this watch, my memory has been deceiving me. I’ve also realised it has taken me nine months to get around to looking at it….

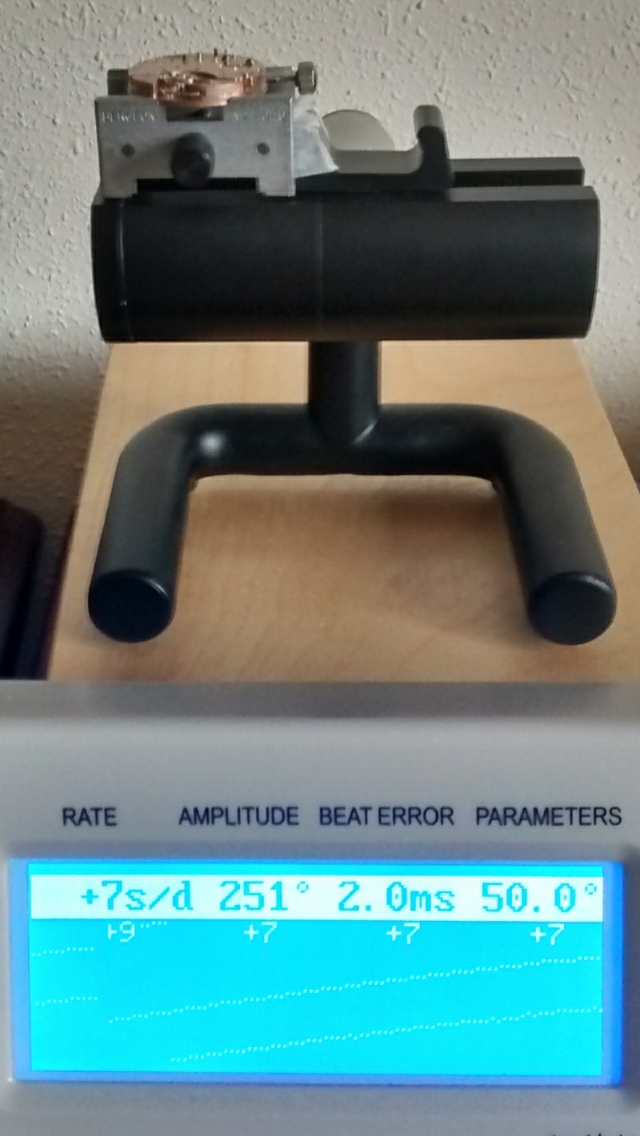

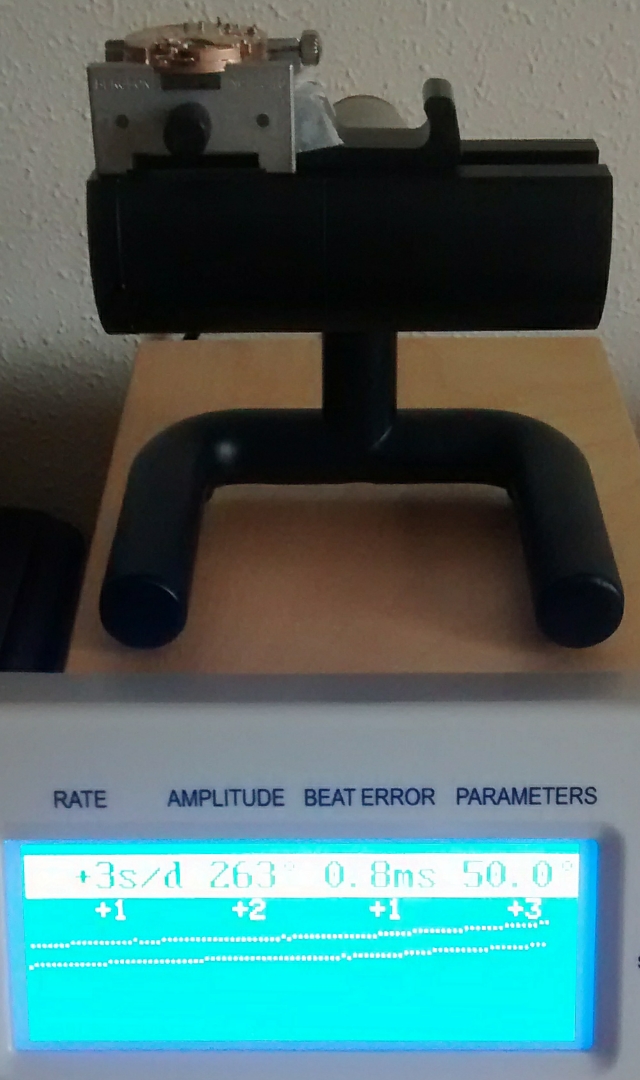

With the balance mounted and having run for a day, the movement looks fine but I have a large beat error so need to fix that before assembling anything else. This is at 24H so, amplitude is pretty good.

Here’s the complete balance assembly which needs adjustment to solve the beat error.

In very simple terms, what you’re basically trying to do here is align the ruby pin of the balance wheel with an imaginary line between the balance jewel and the pallet fork jewel. The error can be either way and the timegrapher doesn’t give an indication of which way it needs to be rotated. Luckily, having been well advised (thanks,

@Archer) I had mounted the balance in the plate before assembling anything to review the hairspring concentricity/flatness etc and at that point, it was easy to see that the jewel appeared to rest a few degrees towards the middle of the movement so, the balance needed to rotate anti-clockwise in this view. This is easy when the top end of the spring (mounted on the balance cock) has an adjustable stud carrier as you can move it around with the movement running and mounted in the timegrapher.

But this is a fixed carrier and this means running in the timegrapher, removing the balance assembly, adjusting, replacing the balance and then iterating until you get the value you want. The top end of the spring is fixed so the balance needs rotating versus the spring at the point where the lower end of the spring is attached to the balance - this is the collet. This is not the easiest thing to move the right amount and one slip here and the hairspring is ruined (new balance at 600 GBP from Cousins!) so am nervous. A couple of iterations and the beat error is down to spec in this orientation but 0.1 or 0.2 above in other orientations. Will leave it to run like that as it might settle a little more (it does).

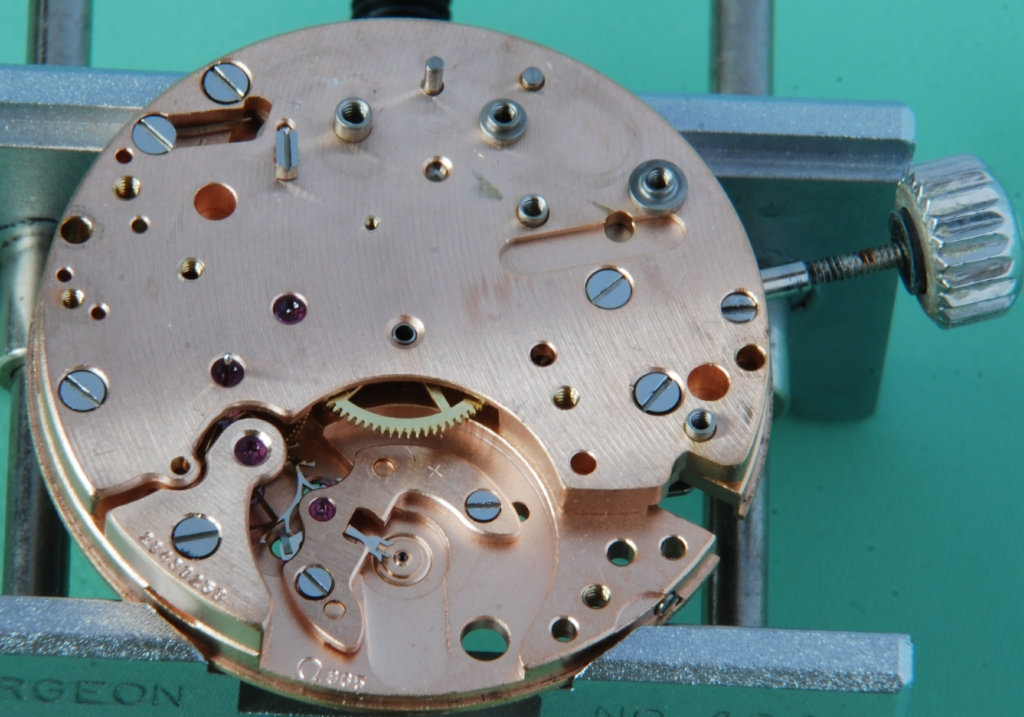

Here are the chronograph parts in the orientation they will mount on the movement.

A few more photos showing this lot back together for later.

Cheers, Chris

Spread it about and hope some if it goes where it's needed. Have been out to my garage and picked up one of these:

Spread it about and hope some if it goes where it's needed. Have been out to my garage and picked up one of these: Spread it about and hope some if it goes where it's needed. Have been out to my garage and picked up one of these:

Spread it about and hope some if it goes where it's needed. Have been out to my garage and picked up one of these: