ChrisN

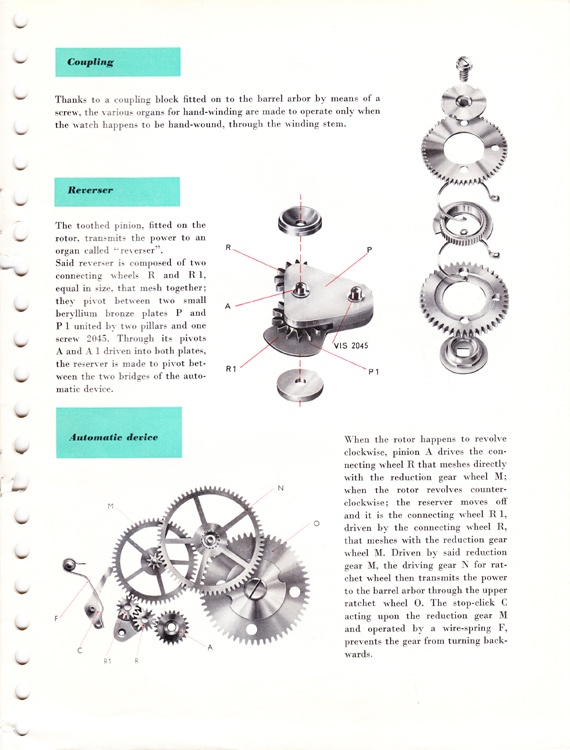

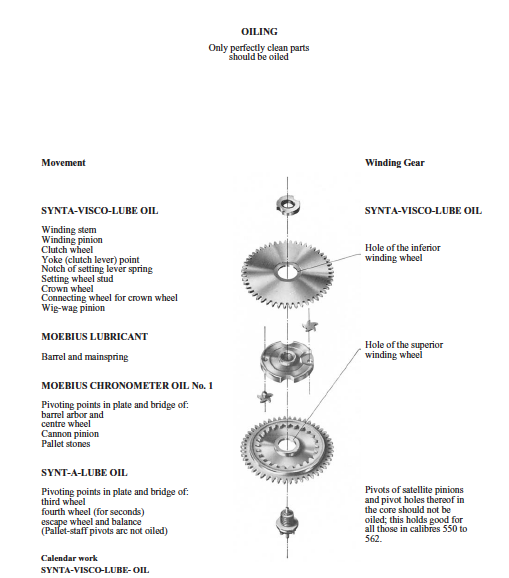

·I have a cal 501 apart at the moment and the ratchet wheel connecting the crown wheel and auto winder to the barrel arbor is an assembly as below.

Working from the left, I'm calling these A to F and this is how I see it working.

The left part, A has a square hole which fits on the barrel arbor so winds the watch when it is turned. It's not clear in the photo but, D, the splined ring, has a flat to engage on A so, it drives the barrel.

There are two toothed rings, B and E, in which the springs are fixed and the end of these springs has a pawl to lock onto the splines on D so that when they turn (in one direction), they turn D and hence the arbor. When they turn the other way, the pawl slips and nothing happens. B connects to the crown wheel and E also to the auto winder.

F screws onto A and holds the assembly together and C is just a washer to keep B and E apart.

Anyway, what do we think about oiling this? When I took it apart there was oil everywhere but that was true of most of this movement....

Am thinking to use HP1300 on the inner diameter of B and E and nothing on either side of the washer. What about on the splines? These are a bit like a date ring as the pawls are clicking into the splines (or sliding depending on direction). A very small amount of HP1300 on the splines?

Cheers, Chris

Working from the left, I'm calling these A to F and this is how I see it working.

The left part, A has a square hole which fits on the barrel arbor so winds the watch when it is turned. It's not clear in the photo but, D, the splined ring, has a flat to engage on A so, it drives the barrel.

There are two toothed rings, B and E, in which the springs are fixed and the end of these springs has a pawl to lock onto the splines on D so that when they turn (in one direction), they turn D and hence the arbor. When they turn the other way, the pawl slips and nothing happens. B connects to the crown wheel and E also to the auto winder.

F screws onto A and holds the assembly together and C is just a washer to keep B and E apart.

Anyway, what do we think about oiling this? When I took it apart there was oil everywhere but that was true of most of this movement....

Am thinking to use HP1300 on the inner diameter of B and E and nothing on either side of the washer. What about on the splines? These are a bit like a date ring as the pawls are clicking into the splines (or sliding depending on direction). A very small amount of HP1300 on the splines?

Cheers, Chris

![IMG_6862[1].JPG IMG_6862[1].JPG](https://omegaforums.net/data/attachments/472/472015-970d94b5c21266d08297b14a8ce0923f.jpg?hash=lw2UtcISZt)