Stewart H

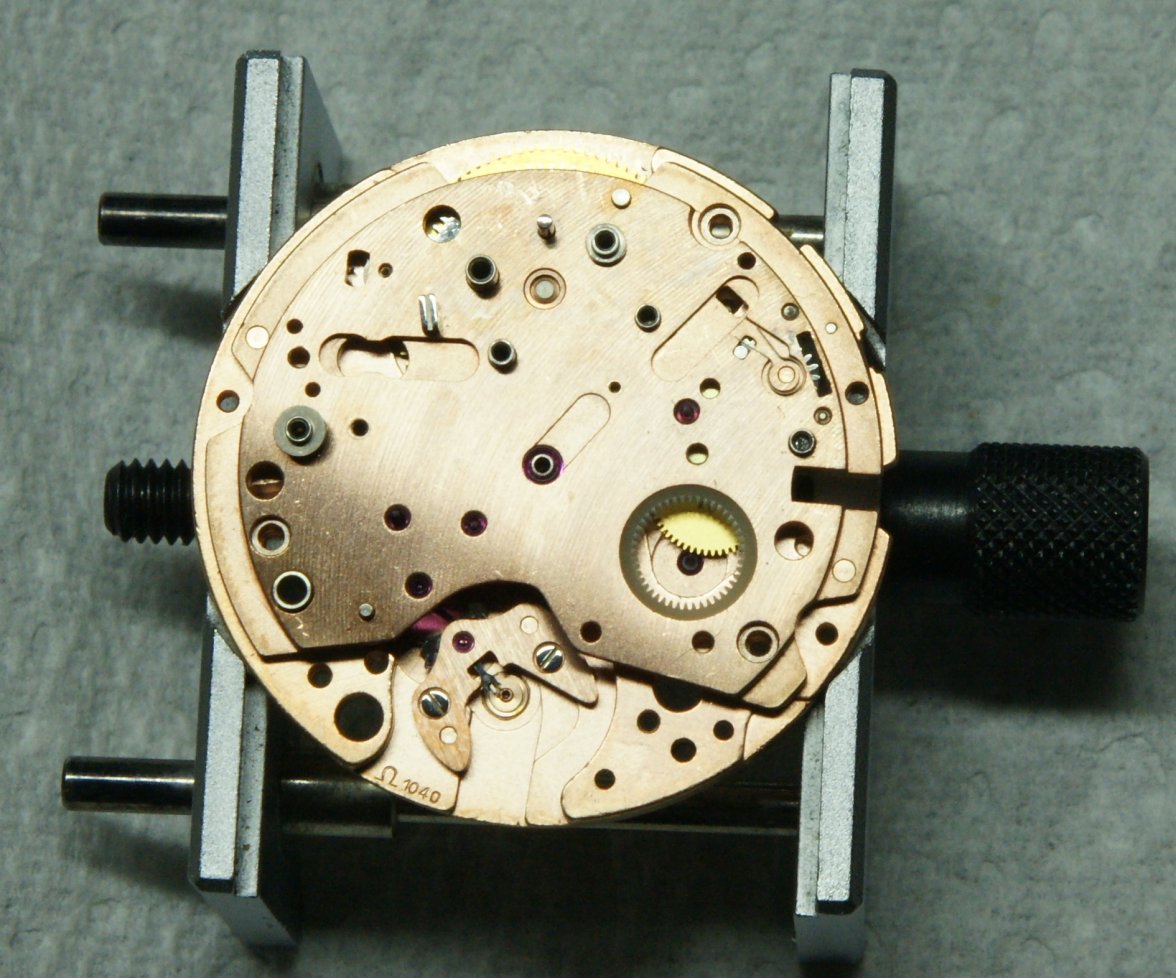

·As I work my way through my project list, I came to the Cal 1040 which has been accused of being Omega's most complicated chronograph and wasn't made for long. It is certainly the most complicated watch I have yet serviced.

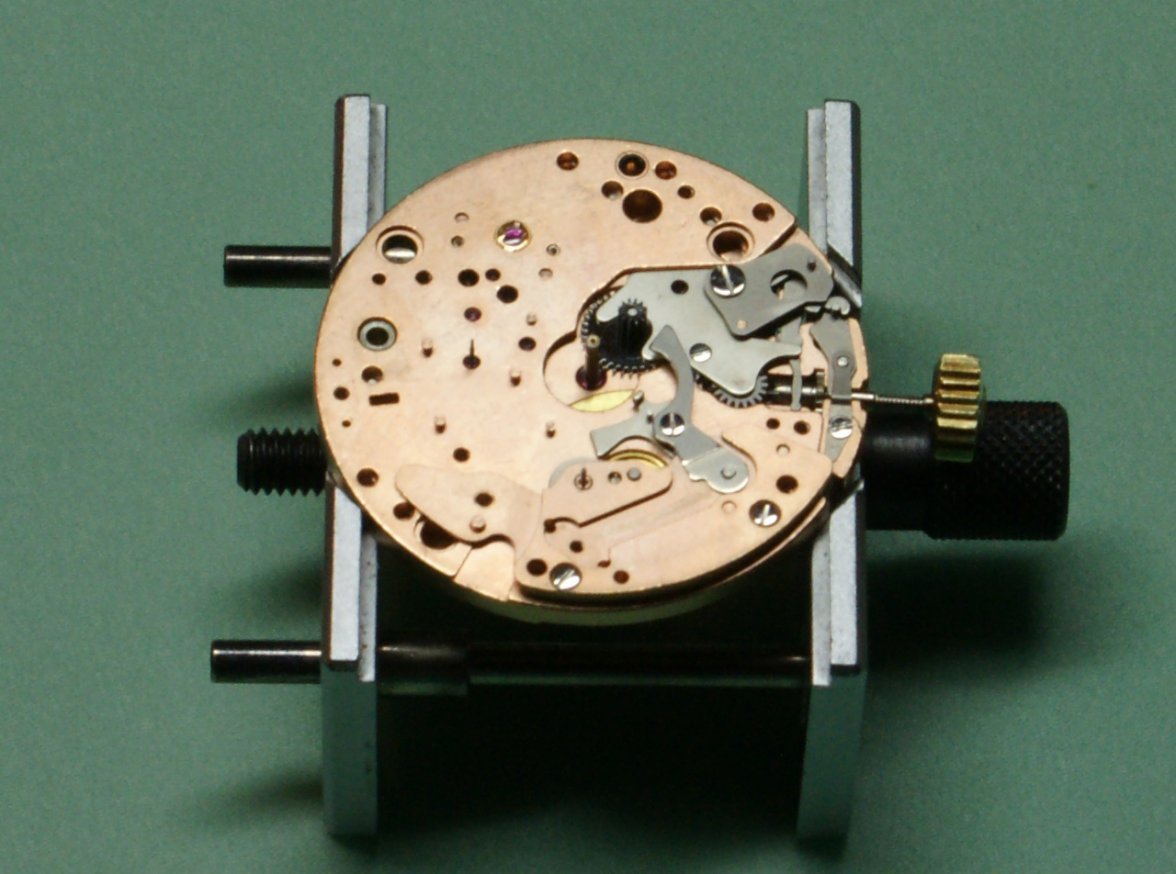

The front and back of the dial:

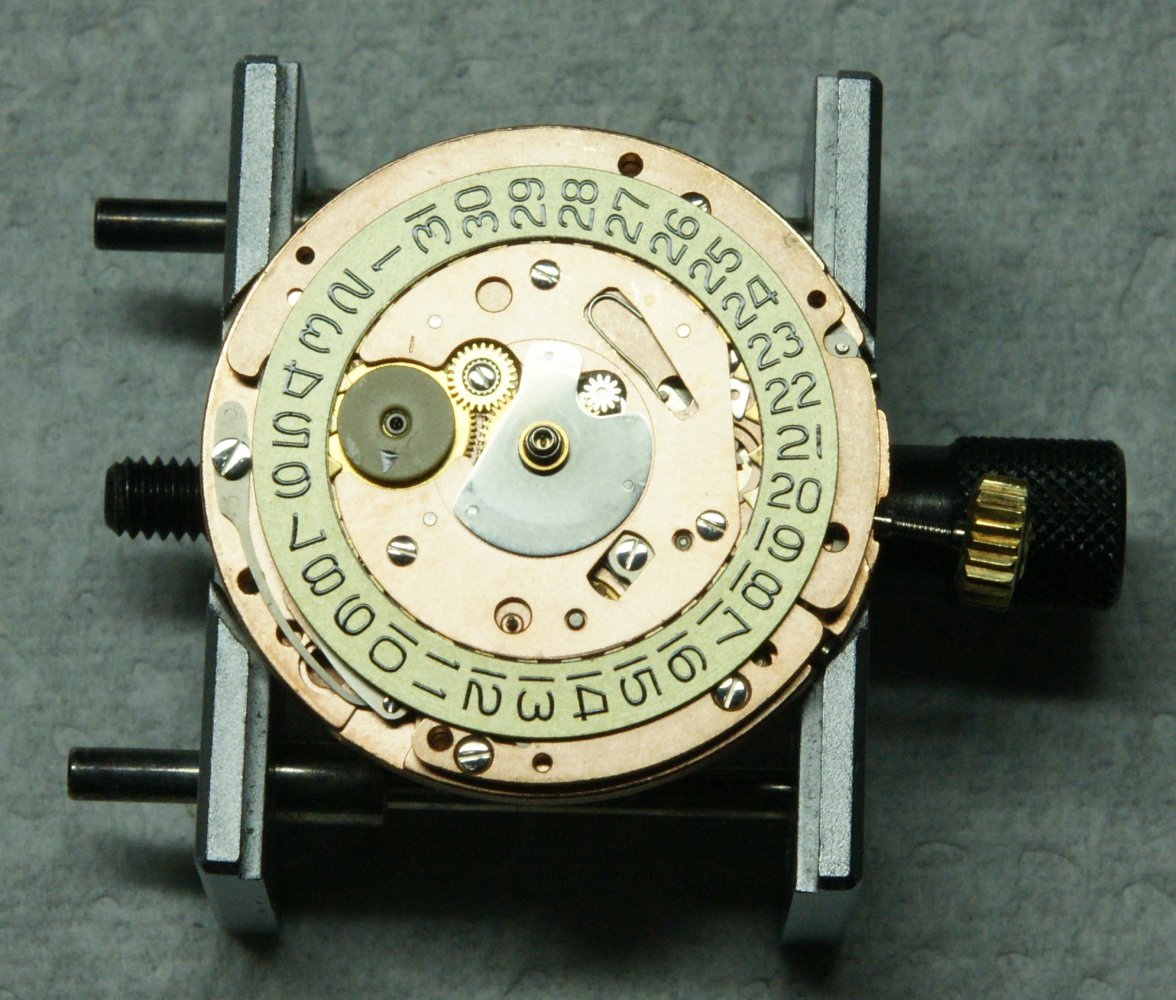

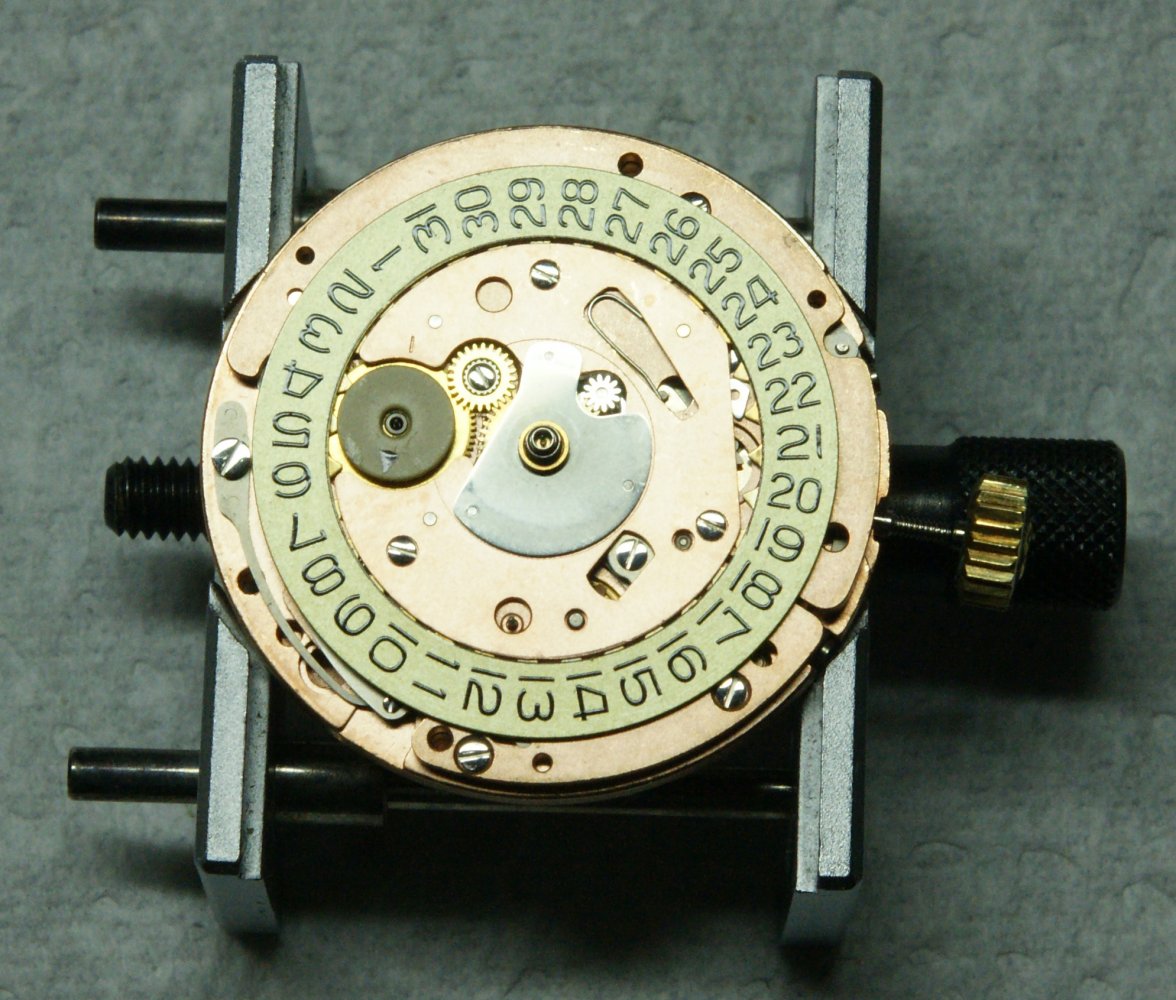

... and what it looks like from the dial side

With the date ring removed

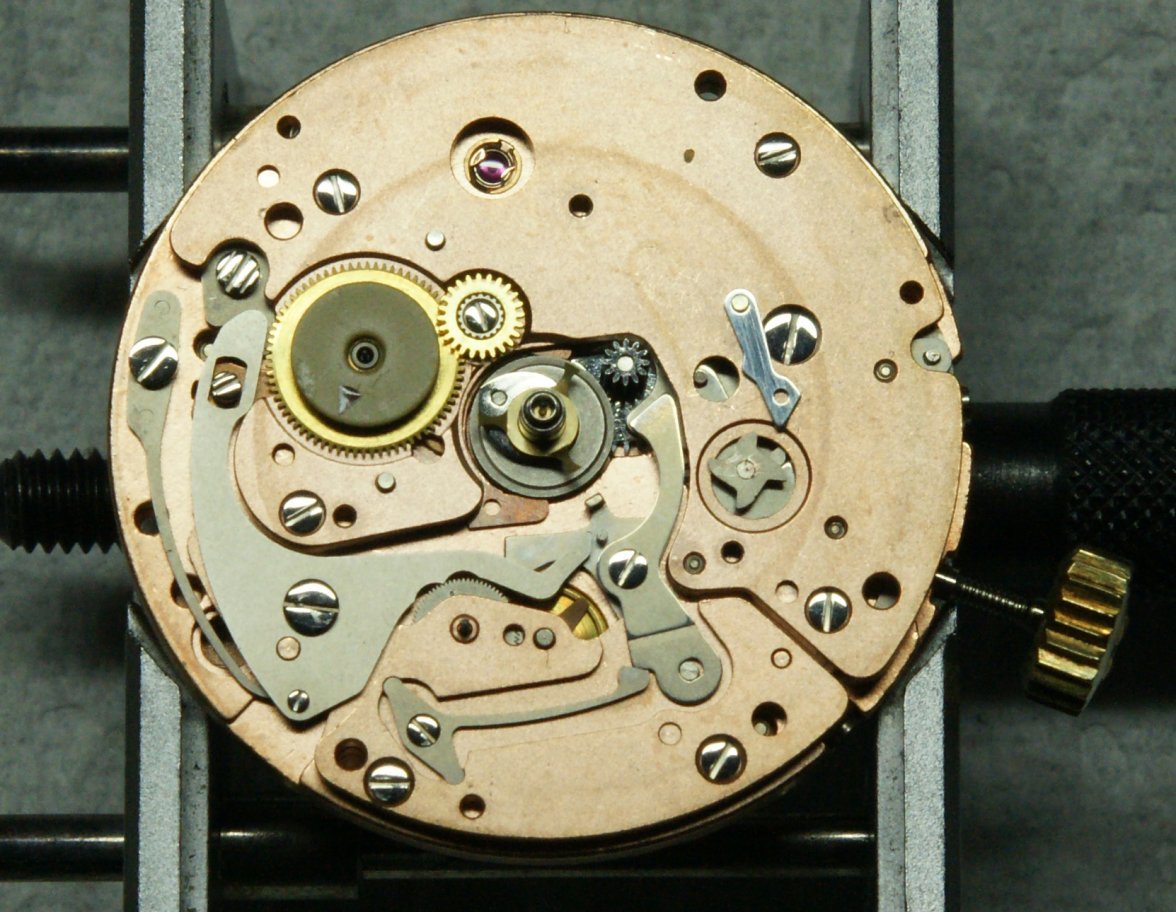

This is where I encountered the first problem. The screw in the middle of the small wheel, next to the day/night indicator, was broken off and had been glued back on. This struck me as strange because it is not expensive to replace a screw. The more eagle-eyed will see the end of the screw, still in the plate in this next photo that also shows the complicated date change mechanism.

It was seized solid and nothing I could do would shift it. Luckily, a used plate came up on eBay and with the very generous help of a forum member in the US, I was able to get hold of it. This is an obsolete part so it could have been catastrophic. So, that's a new screw to order.

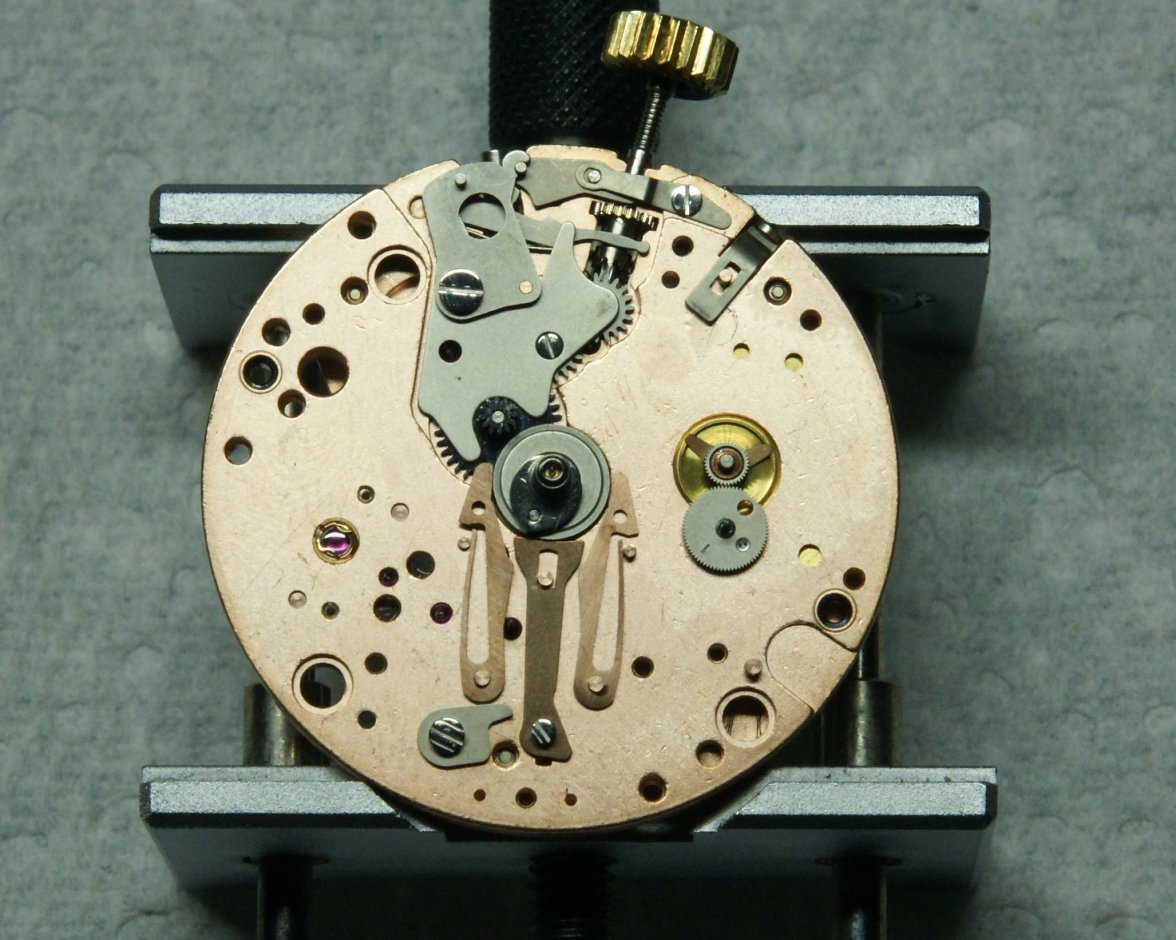

At least I'm through to the dial side of the chronograph mechanism.

Here it is with the operating mechanism removed

We'll come back to this later because the central of the three copper coloured parts was stuck to the plate. This is where I made the mistake of thinking it was a screw holding it down where it is actually an eccentric and it freed up as i was trying to unscrew it.

and it freed up as i was trying to unscrew it.

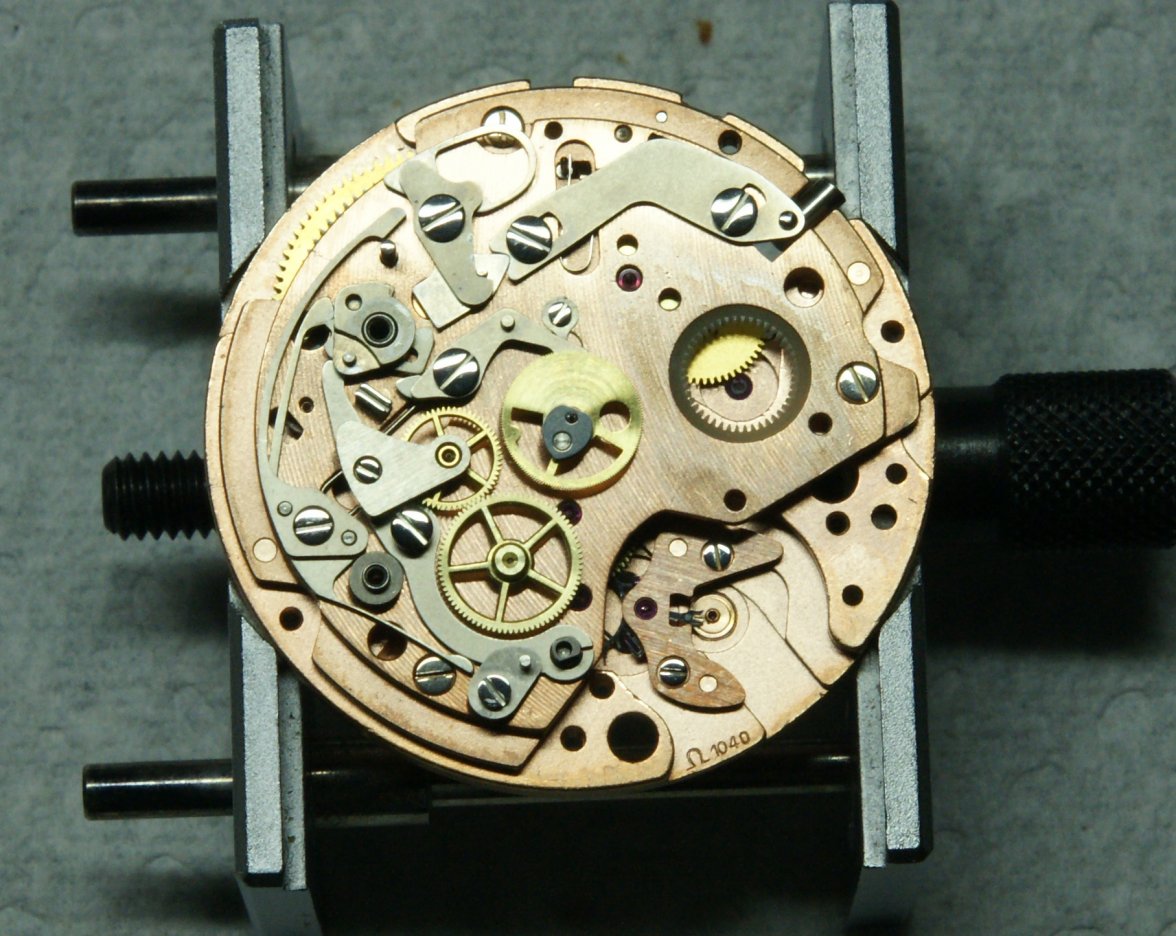

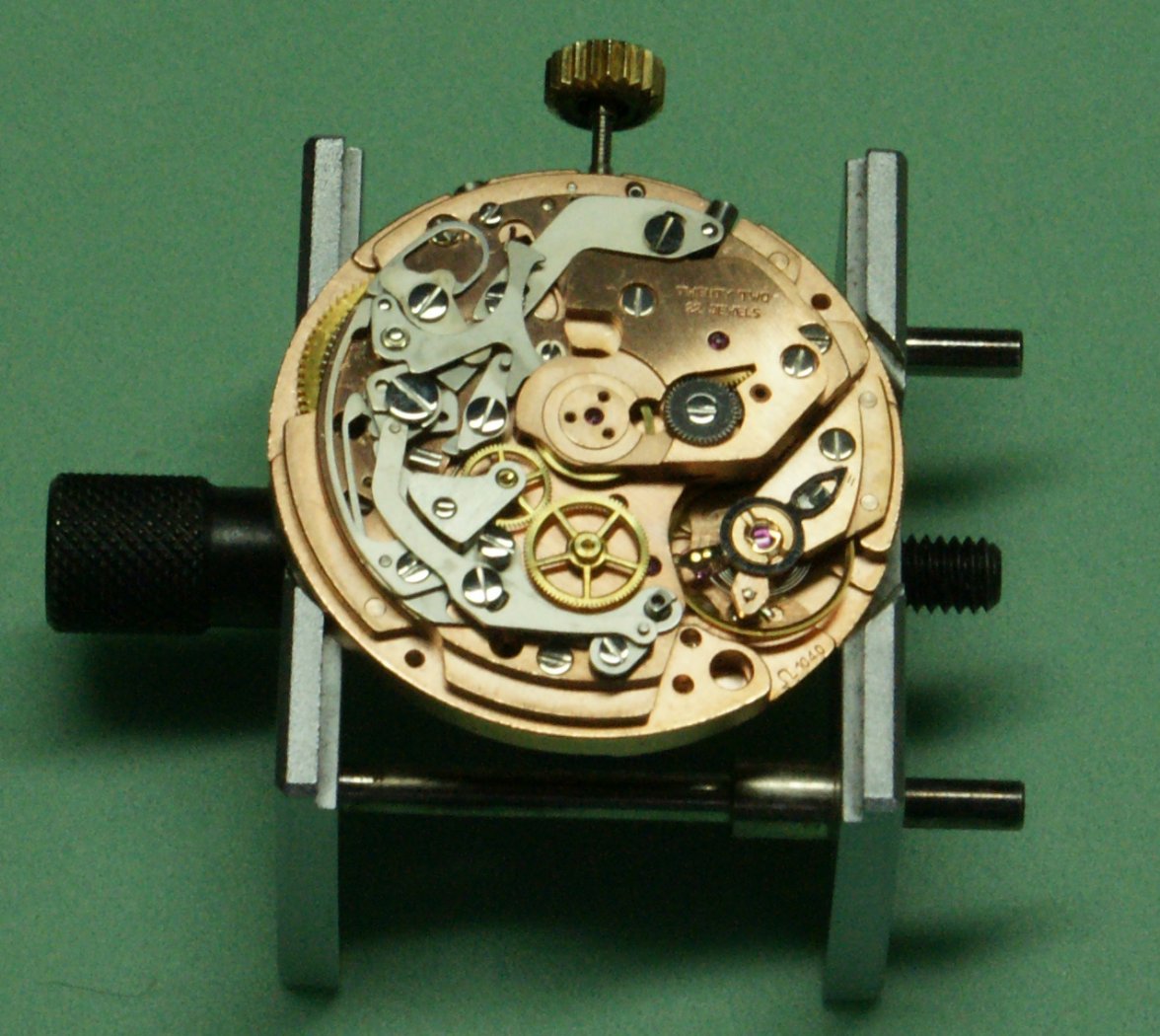

Now we can start on the main chronograph

A lot of this looks familiar if you know the 861.

Here is a picture of the underside of the auto winder bridge

The chronograph starts to come apart

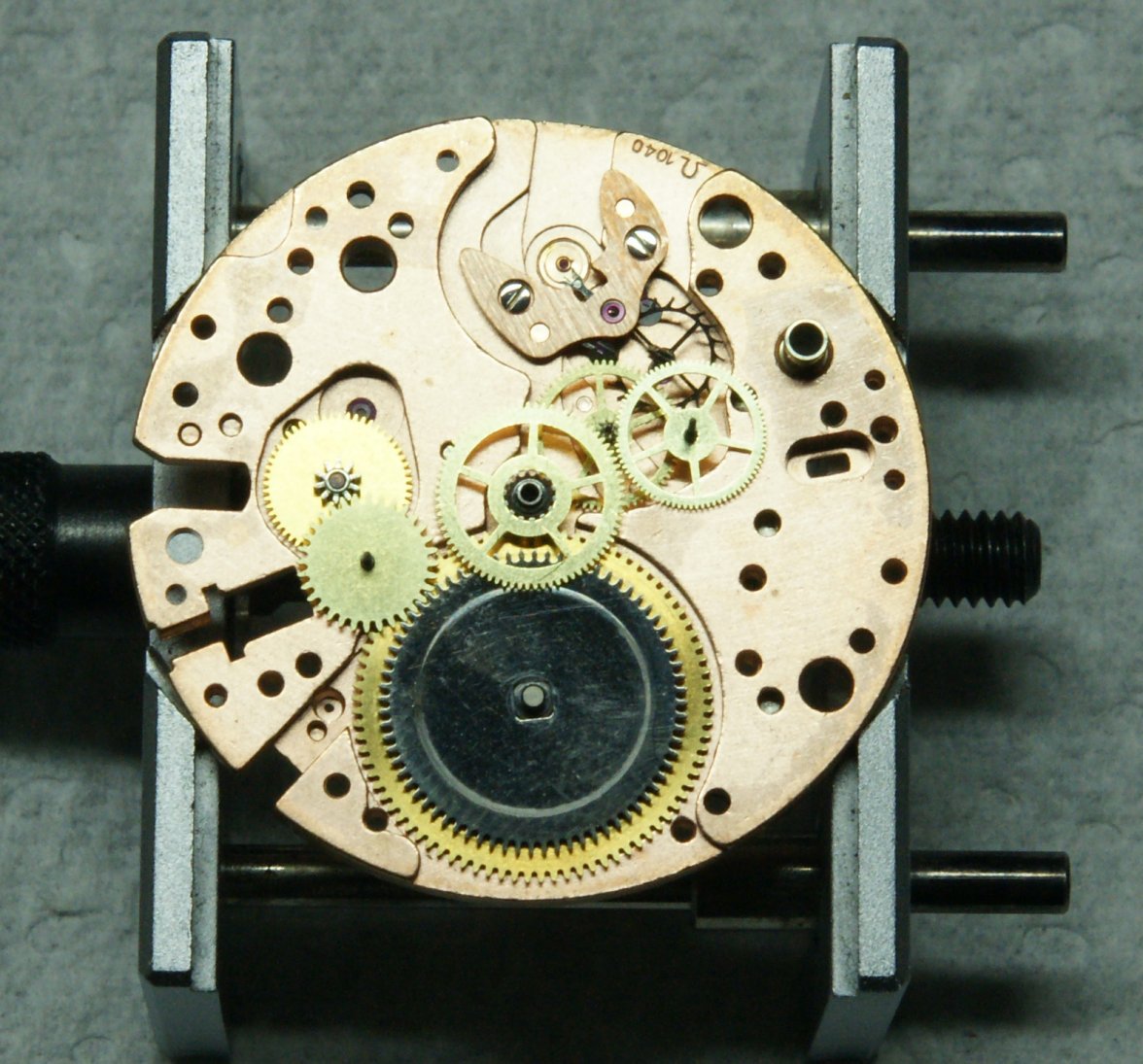

With the chronograph removed, the train bridge is next

This was where I encountered another broken screw but fortunately, this one came out without any trouble.

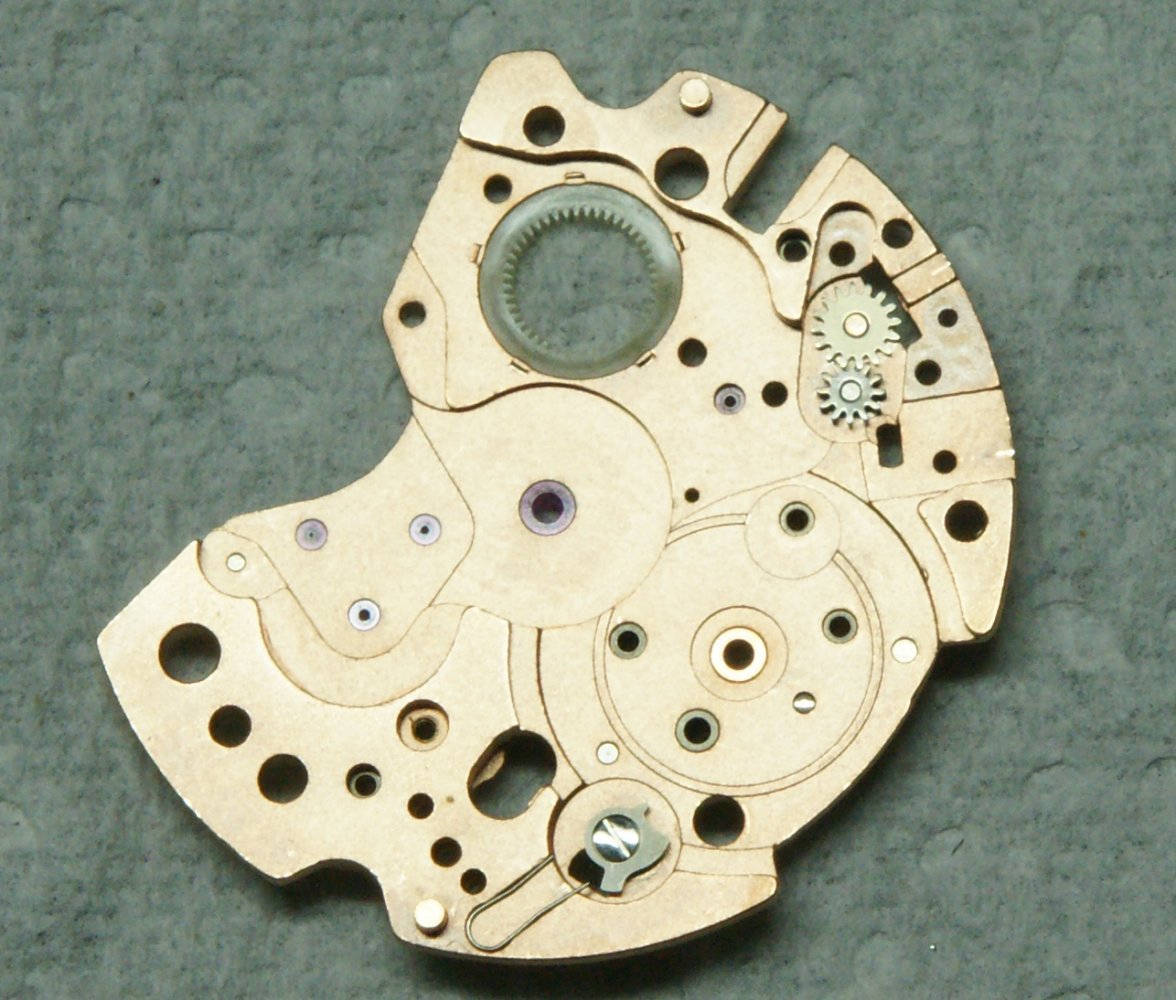

The underside of the bridge

All that is left is the train

As you can see, there is no shortage of parts

Re-assembly is, of course, the opposite of the dis-assembly.

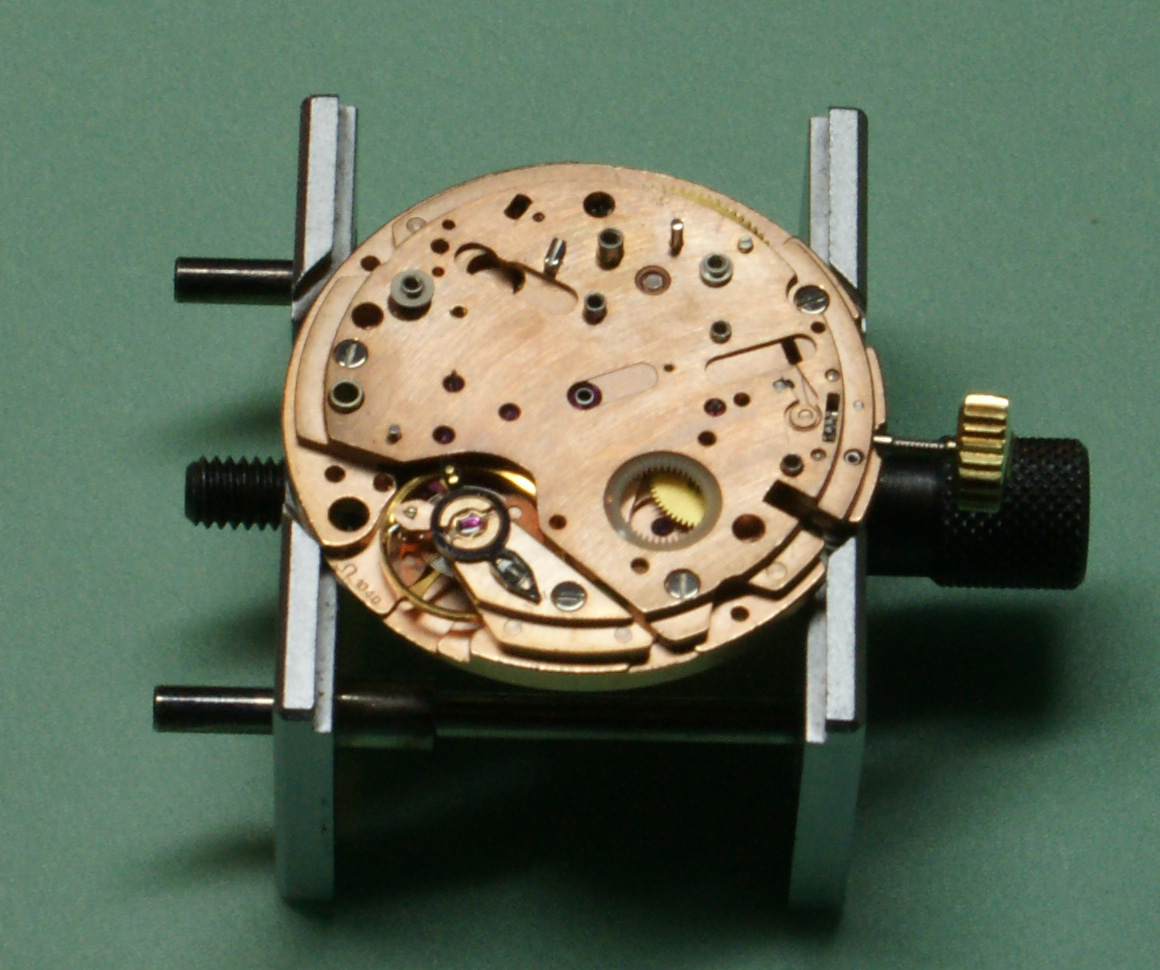

The basic watch, back up and running - well it wasn't quite as simple as that. I ended up chasing my tail as the amplitude was originally very low and as I adjusted one jewel, it led to the need to adjust another.... and so on. Still, I got there in the end.

Just like the 861, you have to assemble the hour recorded to get the watch running because the runner is driven directly by the barrel assembly and the bridge for the runner supports the barrel arbour.

So onto the chronograph. This side went together without any trouble:

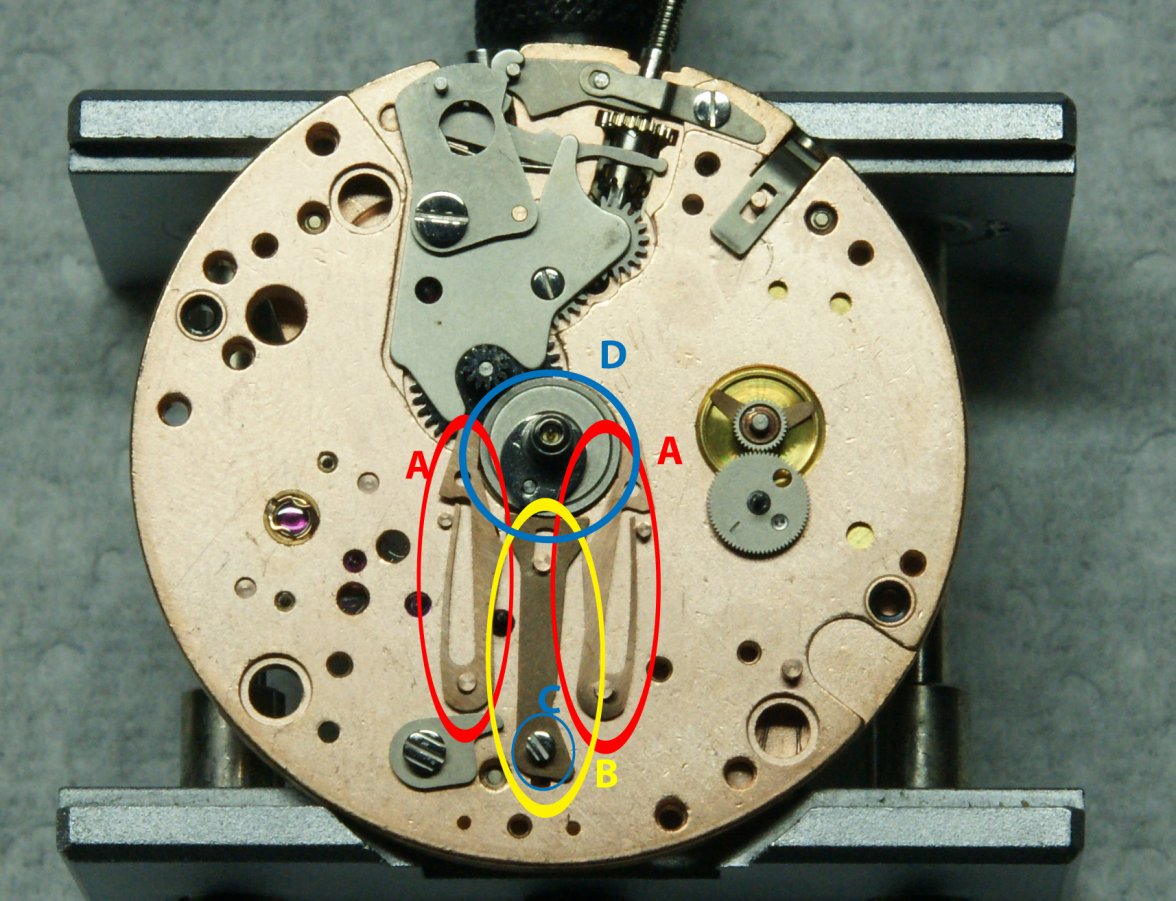

You'll remember that I tried unscrewing that eccentric so let's have a look at how the mechanism for locking the sweep minute recorder works:

When the chronograph is not running, the minute recording driver "D" is locked in position by the two clamps "A". Starting the chronograph, a lever pulls on the eccentric "C" mounted on the Valet for Minute Recorder Clamp "B", moving it downwards and forcing the clamps apart, thus allowing the minute recorder to rotate. Stopping the chronograph moves the valet back upwards, letting the clamps back in against the runner. Now, here is the clever bit; when you push the reset, the runner has to be free to move so the clamps are forced apart just before the reset hammer strikes the heart mounted on the runner. That was a real pain to adjust just right but needless to say, I got there in the end......

..... well nearly.

When I had put the dial back on, last weekend, I discovered that the pipe on the minute recording hand was split but a replacement hand was easy to get and yesterday, I rebuilt the stack of hands and finished the job.

The last thing is to put the oscillating weight back on.

So there we have it, the over engineered, expensive to make and complicated to maintain, Omega Cal 1040.

It is little wonder that they didn't make it for long and replaced it with the 1045, using the DD module mounted on a plastic plate.

Having said that, I love the movement and have really enjoyed the journey - frustrating but hugely rewarding.

The front and back of the dial:

... and what it looks like from the dial side

With the date ring removed

This is where I encountered the first problem. The screw in the middle of the small wheel, next to the day/night indicator, was broken off and had been glued back on. This struck me as strange because it is not expensive to replace a screw. The more eagle-eyed will see the end of the screw, still in the plate in this next photo that also shows the complicated date change mechanism.

It was seized solid and nothing I could do would shift it. Luckily, a used plate came up on eBay and with the very generous help of a forum member in the US, I was able to get hold of it. This is an obsolete part so it could have been catastrophic. So, that's a new screw to order.

At least I'm through to the dial side of the chronograph mechanism.

Here it is with the operating mechanism removed

We'll come back to this later because the central of the three copper coloured parts was stuck to the plate. This is where I made the mistake of thinking it was a screw holding it down where it is actually an eccentric

and it freed up as i was trying to unscrew it.

and it freed up as i was trying to unscrew it.Now we can start on the main chronograph

A lot of this looks familiar if you know the 861.

Here is a picture of the underside of the auto winder bridge

The chronograph starts to come apart

With the chronograph removed, the train bridge is next

This was where I encountered another broken screw but fortunately, this one came out without any trouble.

The underside of the bridge

All that is left is the train

As you can see, there is no shortage of parts

Re-assembly is, of course, the opposite of the dis-assembly.

The basic watch, back up and running - well it wasn't quite as simple as that. I ended up chasing my tail as the amplitude was originally very low and as I adjusted one jewel, it led to the need to adjust another.... and so on. Still, I got there in the end.

Just like the 861, you have to assemble the hour recorded to get the watch running because the runner is driven directly by the barrel assembly and the bridge for the runner supports the barrel arbour.

So onto the chronograph. This side went together without any trouble:

You'll remember that I tried unscrewing that eccentric so let's have a look at how the mechanism for locking the sweep minute recorder works:

When the chronograph is not running, the minute recording driver "D" is locked in position by the two clamps "A". Starting the chronograph, a lever pulls on the eccentric "C" mounted on the Valet for Minute Recorder Clamp "B", moving it downwards and forcing the clamps apart, thus allowing the minute recorder to rotate. Stopping the chronograph moves the valet back upwards, letting the clamps back in against the runner. Now, here is the clever bit; when you push the reset, the runner has to be free to move so the clamps are forced apart just before the reset hammer strikes the heart mounted on the runner. That was a real pain to adjust just right but needless to say, I got there in the end......

..... well nearly.

When I had put the dial back on, last weekend, I discovered that the pipe on the minute recording hand was split but a replacement hand was easy to get and yesterday, I rebuilt the stack of hands and finished the job.

The last thing is to put the oscillating weight back on.

So there we have it, the over engineered, expensive to make and complicated to maintain, Omega Cal 1040.

It is little wonder that they didn't make it for long and replaced it with the 1045, using the DD module mounted on a plastic plate.

Having said that, I love the movement and have really enjoyed the journey - frustrating but hugely rewarding.

Edited: