ChrisN

·This has been on my to do list for years and I may just have sufficient knowledge to do it now. These 1960s Smiths clocks sit in the lower of a Smiths Rev counter and are a separate unit. It's a clever mechanism so might be of interest to some here. Nowadays, I suppose all car clocks are quartz but before the advent of stepper motors, Smiths needed a way to make a cheap movement to do the same thing.

Here in my '63 E-Type. I'd previously stripped all the gauges and cleaned them but kept putting this clock back in without even cleaning it's case. Always next month, well next month arrived. This did work intermittently years ago and makes a noise similar to a mechanical watch.

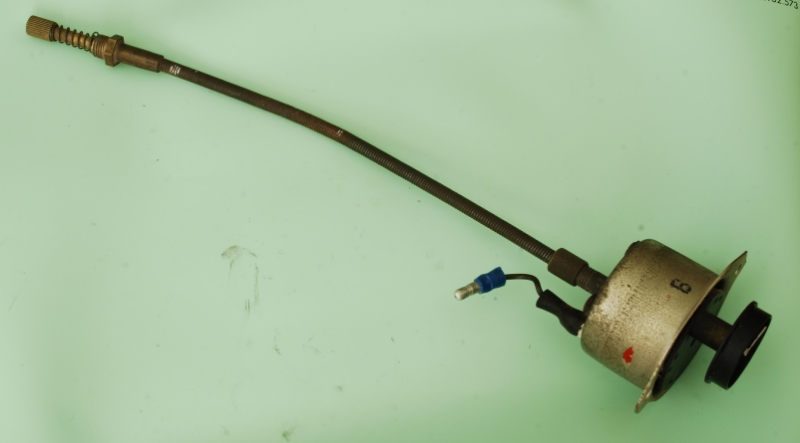

Out of the car with the setting cable (found after thirty minutes in the garage..). The dial part is only about an inch in diameter and the case closer to two inches.

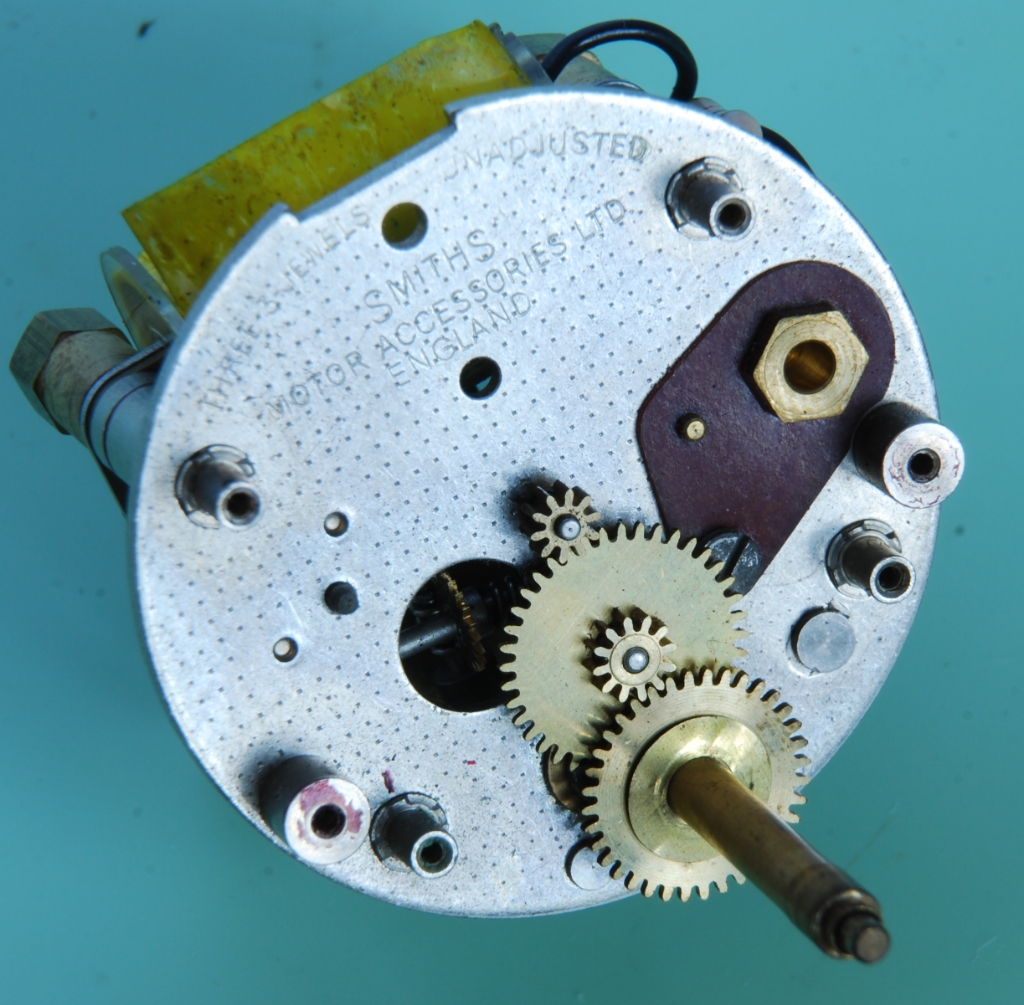

The back with one electrical connection (the earth is through the rev counter body) on the right. My car was positive earth when made so it says "feed lead negative". Makes no difference as it works with negative earth. There's a hole to turn the regulator just above the central shaft but, it's hidden. The mechanism is held and suspended from the body on the four big screws sitting in rubber bushes but, one of them is earthed with the little strip. This means the whole movement is earthed so the electrical parts sit on insulators.

Out of it's case and on the dirty strip down mat. There's a balance wheel and hairspring with regulator on this side. It's this side that needs to be connected to earth as the electrical path is through the hairspring....

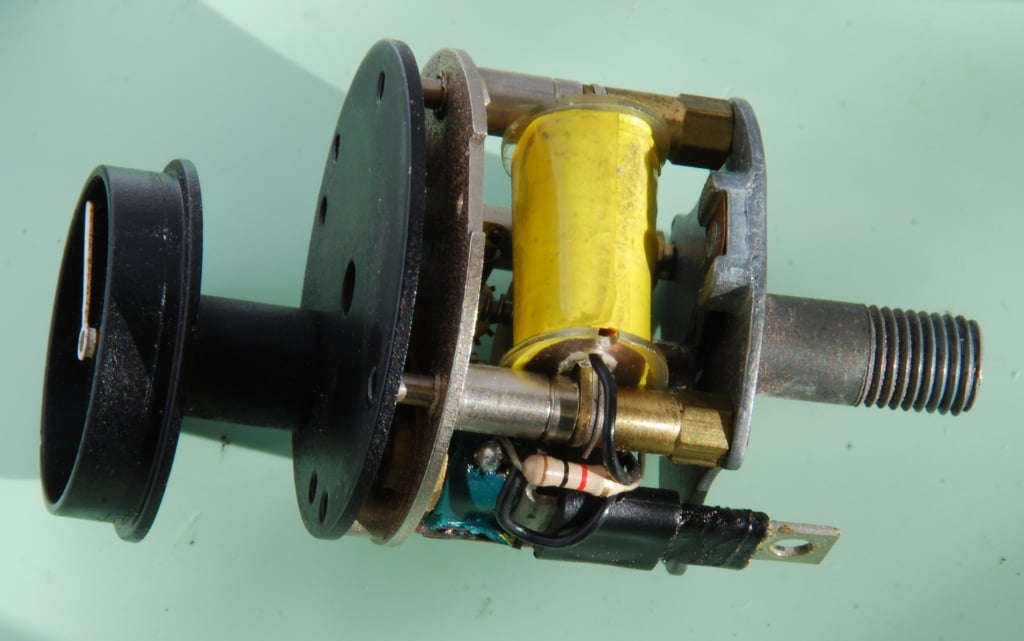

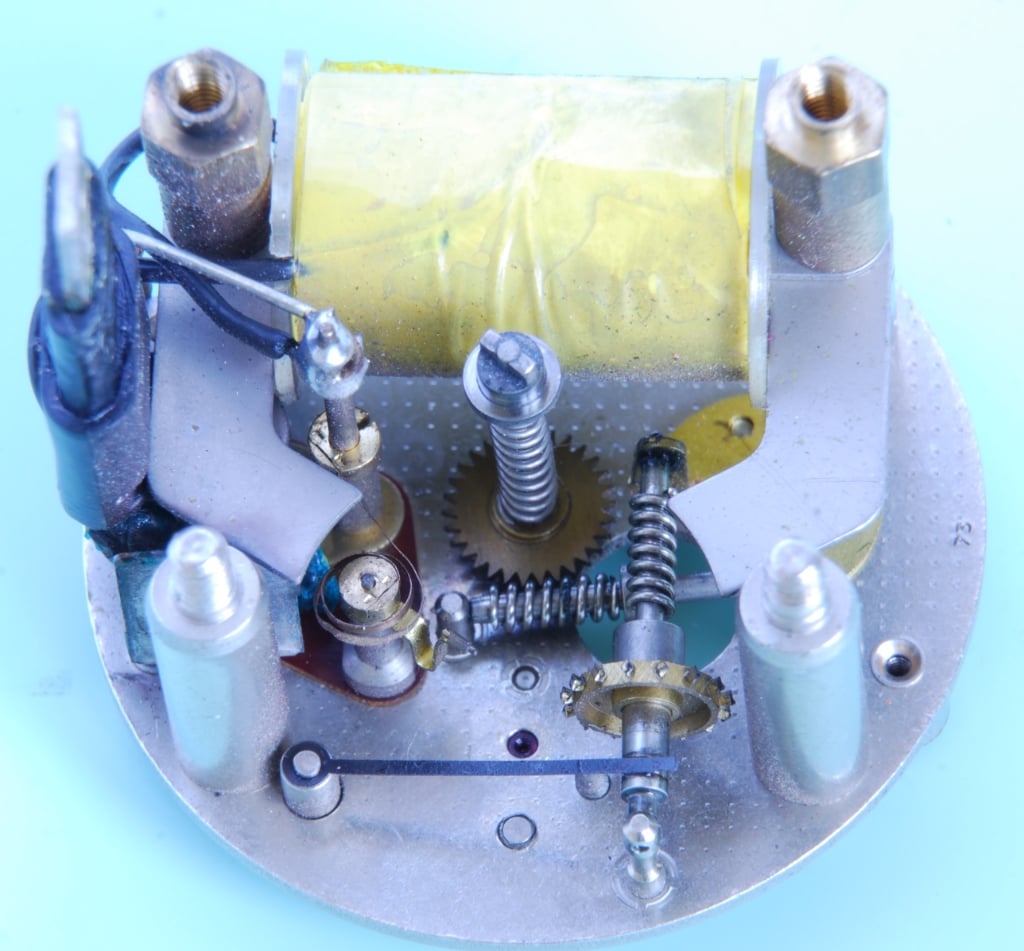

On the other side, a coil to generate a magnetic field.

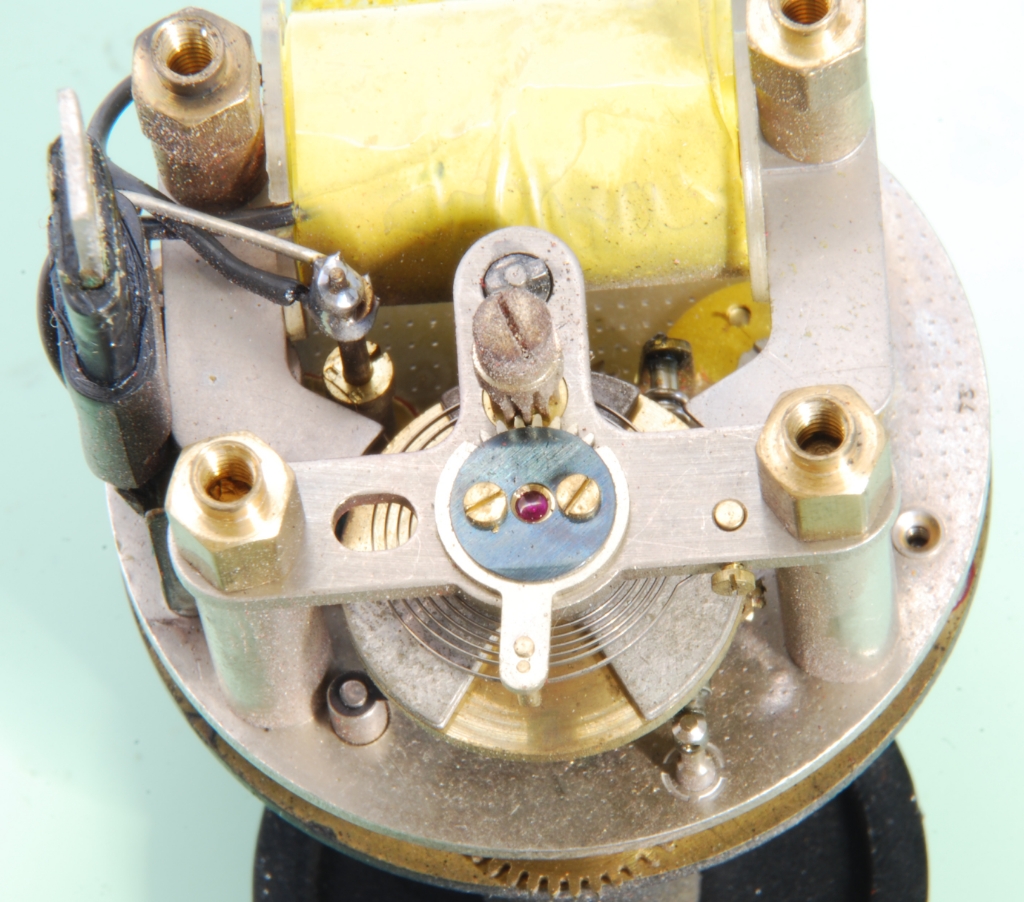

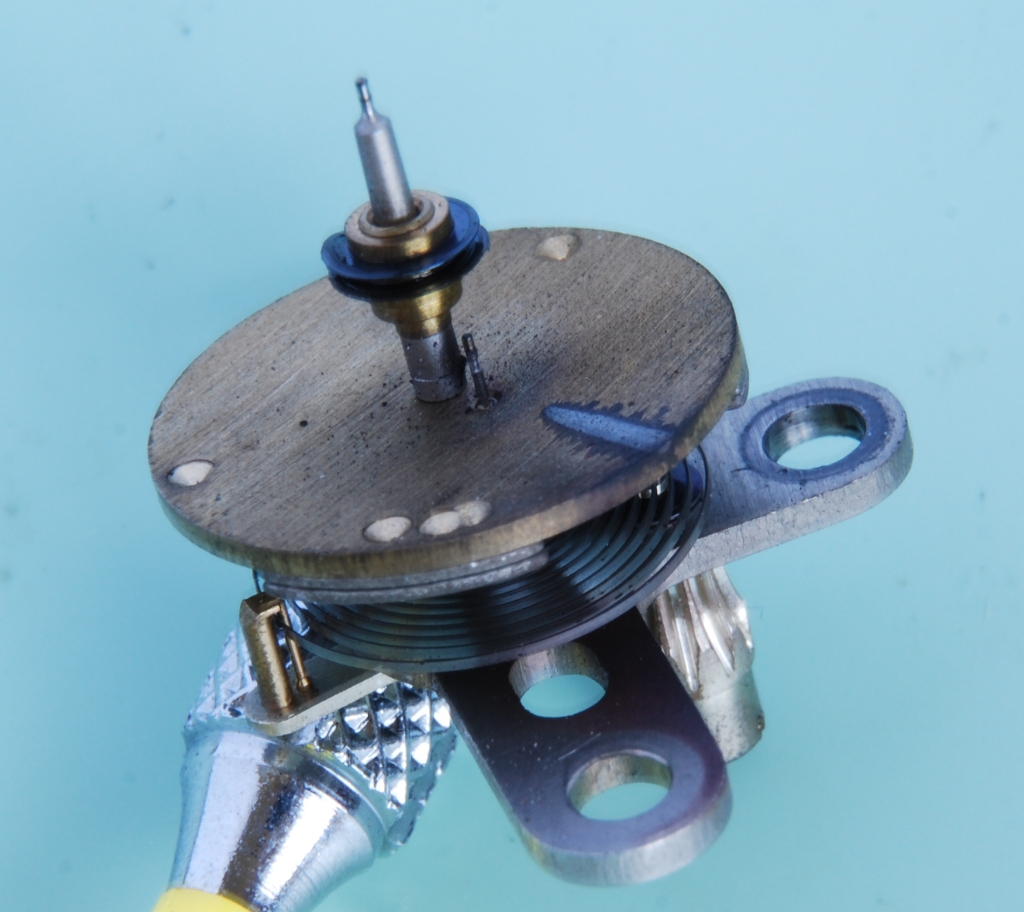

Better view of the balance and hairspring, stud on the right and regulator in the middle, with the screw that comes through the case to adjust the rate. The balance has three permanent magnet segments. This cap jewel is one of the three jewels (the other two being for the balance pinions).

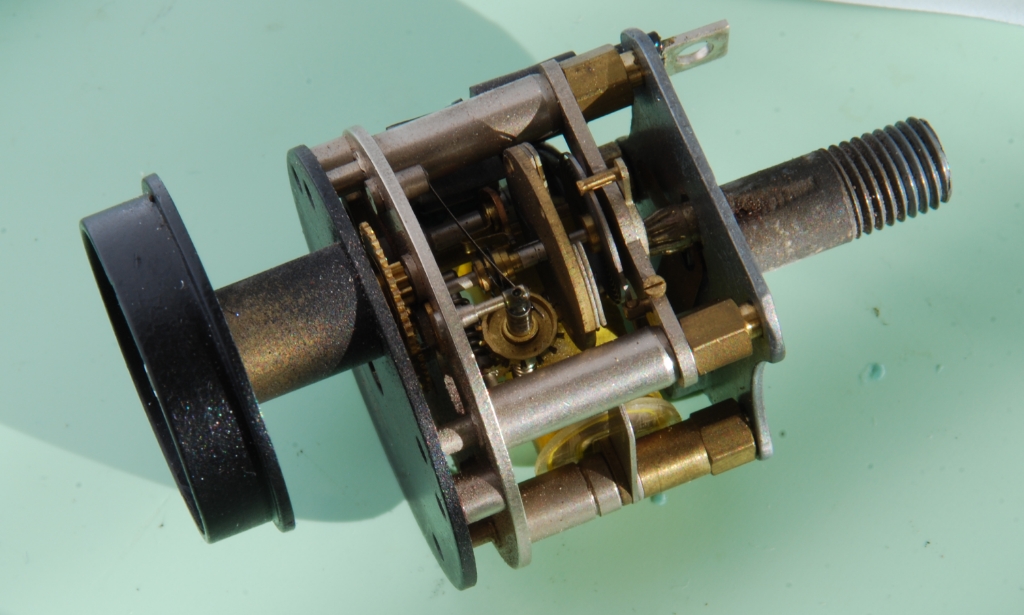

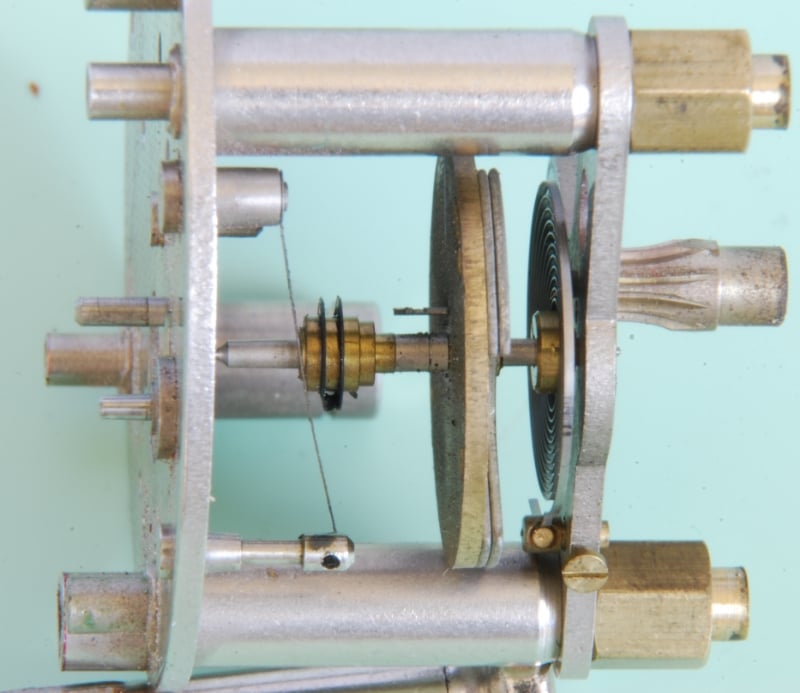

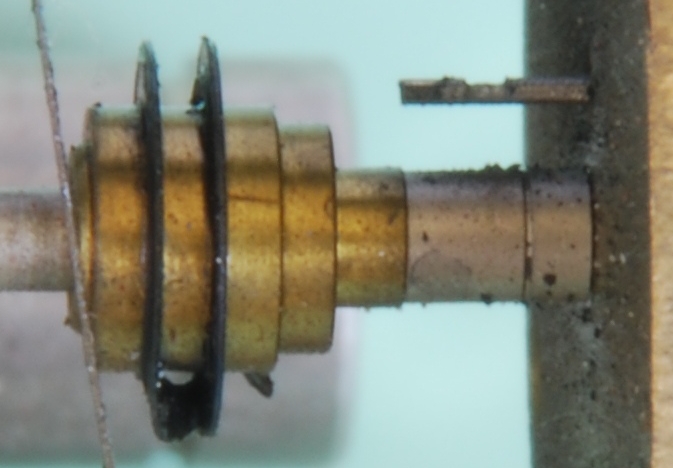

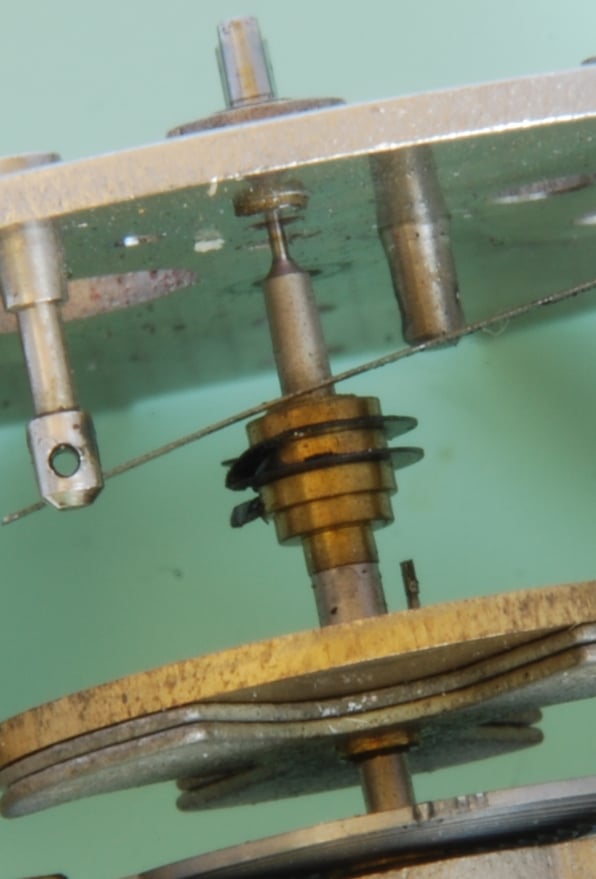

Balance removed. The balance drives the movement and is not there to control the energy release from a mainspring. When it swings, it drives the brass collar on the right hand shaft (that shaft has a piece of spring steel resting on it to stop flutter). When that shaft turns, the worm gear drives the horizontal shaft and it's worm gear drives the central shaft via it's wheel.

On the 'dial' side, the central shaft drives these gears to run the minute and hour hands on the long shafts. Note that some halfwit used red loctite to attach this side meaning I had to heat it to get the screws out...

Here's the balance turned over. The black ring is the one that drives the brass collar above. There's a pin sticking down close to the shaft and as it swings, that contacts the spring in the next picture to complete the circuit to earth via the balance spring. There's some burning on the balance probably caused by arcing due to poor earthing. It also has Endshake measured in mm so, it may be touching something.

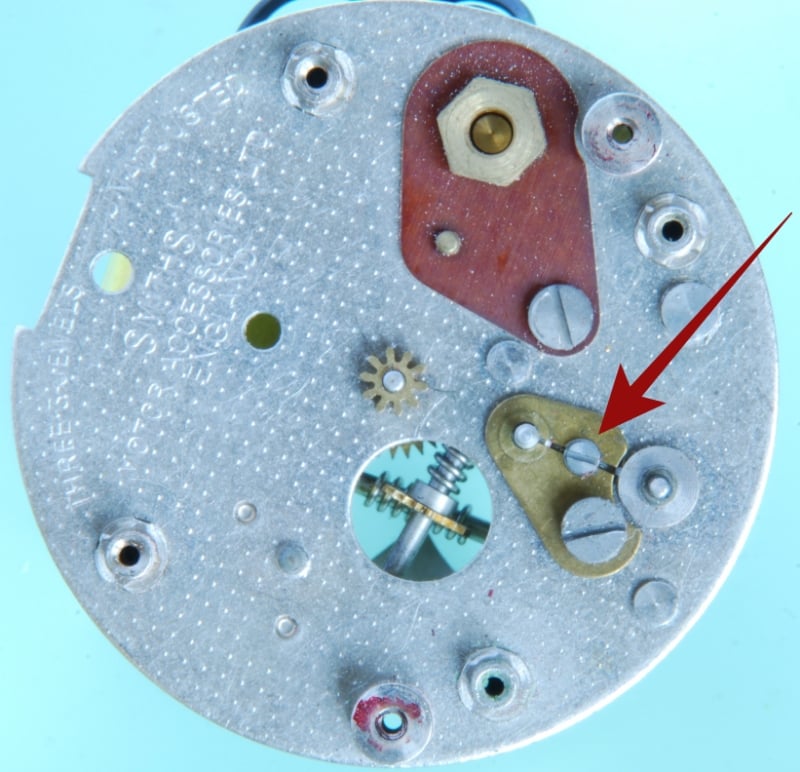

Here's the electrical parts removed. The one connection on the back goes to the coil on one side and the other side of the coil is connected to the post with solder. That's connected to the post at 12 O'clock via a spring and the prong sticking out is the one that contacts the pin on the balance wheel.

This is pretty clever and like a small DC motor (although usually, the armature has the magnets controlled by the power). But, it can't be allowed to turn continuously so it needs to be stopped and started.

When the balance swings the pin contacts the prong above completing the coil circuit and generates a magnetic field down the two curved arms. The permanent magnets in the balance react with that to give an impulse to the balance and the mechanism is driven. It's all controlled for rate by the effective balance spring length the same as in a mechanical watch. To start it, the circuit is completed with another mechanism.

It has some problems, excluding the dial and hands that I will need to repaint. The pin and prong are working like points in a distributor so get eaten away. I suspect this is the biggest problem with it.

Easy to repaint the dial but, I want to keep the writing, which is just the Smiths part number. Made the mistake of trying to polish out a score and now it's terrible...

Hands will be fine when painted.

So, it's stripped and will be cleaned (I'll take any oiling advice) to see if I can get it going again.

Cheers, Chris

Here in my '63 E-Type. I'd previously stripped all the gauges and cleaned them but kept putting this clock back in without even cleaning it's case. Always next month, well next month arrived. This did work intermittently years ago and makes a noise similar to a mechanical watch.

Out of the car with the setting cable (found after thirty minutes in the garage..). The dial part is only about an inch in diameter and the case closer to two inches.

The back with one electrical connection (the earth is through the rev counter body) on the right. My car was positive earth when made so it says "feed lead negative". Makes no difference as it works with negative earth. There's a hole to turn the regulator just above the central shaft but, it's hidden. The mechanism is held and suspended from the body on the four big screws sitting in rubber bushes but, one of them is earthed with the little strip. This means the whole movement is earthed so the electrical parts sit on insulators.

Out of it's case and on the dirty strip down mat. There's a balance wheel and hairspring with regulator on this side. It's this side that needs to be connected to earth as the electrical path is through the hairspring....

On the other side, a coil to generate a magnetic field.

Better view of the balance and hairspring, stud on the right and regulator in the middle, with the screw that comes through the case to adjust the rate. The balance has three permanent magnet segments. This cap jewel is one of the three jewels (the other two being for the balance pinions).

Balance removed. The balance drives the movement and is not there to control the energy release from a mainspring. When it swings, it drives the brass collar on the right hand shaft (that shaft has a piece of spring steel resting on it to stop flutter). When that shaft turns, the worm gear drives the horizontal shaft and it's worm gear drives the central shaft via it's wheel.

On the 'dial' side, the central shaft drives these gears to run the minute and hour hands on the long shafts. Note that some halfwit used red loctite to attach this side meaning I had to heat it to get the screws out...

Here's the balance turned over. The black ring is the one that drives the brass collar above. There's a pin sticking down close to the shaft and as it swings, that contacts the spring in the next picture to complete the circuit to earth via the balance spring. There's some burning on the balance probably caused by arcing due to poor earthing. It also has Endshake measured in mm so, it may be touching something.

Here's the electrical parts removed. The one connection on the back goes to the coil on one side and the other side of the coil is connected to the post with solder. That's connected to the post at 12 O'clock via a spring and the prong sticking out is the one that contacts the pin on the balance wheel.

This is pretty clever and like a small DC motor (although usually, the armature has the magnets controlled by the power). But, it can't be allowed to turn continuously so it needs to be stopped and started.

When the balance swings the pin contacts the prong above completing the coil circuit and generates a magnetic field down the two curved arms. The permanent magnets in the balance react with that to give an impulse to the balance and the mechanism is driven. It's all controlled for rate by the effective balance spring length the same as in a mechanical watch. To start it, the circuit is completed with another mechanism.

It has some problems, excluding the dial and hands that I will need to repaint. The pin and prong are working like points in a distributor so get eaten away. I suspect this is the biggest problem with it.

Easy to repaint the dial but, I want to keep the writing, which is just the Smiths part number. Made the mistake of trying to polish out a score and now it's terrible...

Hands will be fine when painted.

So, it's stripped and will be cleaned (I'll take any oiling advice) to see if I can get it going again.

Cheers, Chris