ErichKeane

·I've been keeping an eye on these for quite a while now, they seemed really interesting, and an office clock would be pretty nice.

I have however been unwilling to pay the going rate for one on Ebay.

I kept an eye out though, and found THIS one for sale on French Ebay, listed as 'doesn't work'. I submitted an insulting 'make an offer' figuring it would get rejected, and moved on with my evening. THEN, I got a message the next morning that my offer was accepted! It took a while to ship, but showed up today.

First impressions: The dial/glass/etc is in beautiful shape. The case itself is a little dirty/has some marks on it, but is otherwise pretty fantastic. I'm missing the 'rubber'-esque bottom on the body, but otherwise it seems complete (minus a 9v!).

Size wise, this is WAAAY smaller than I expected. It is about the size of a beer can, and about 2x as heavy. The base itself is a REALLY heavy guy.

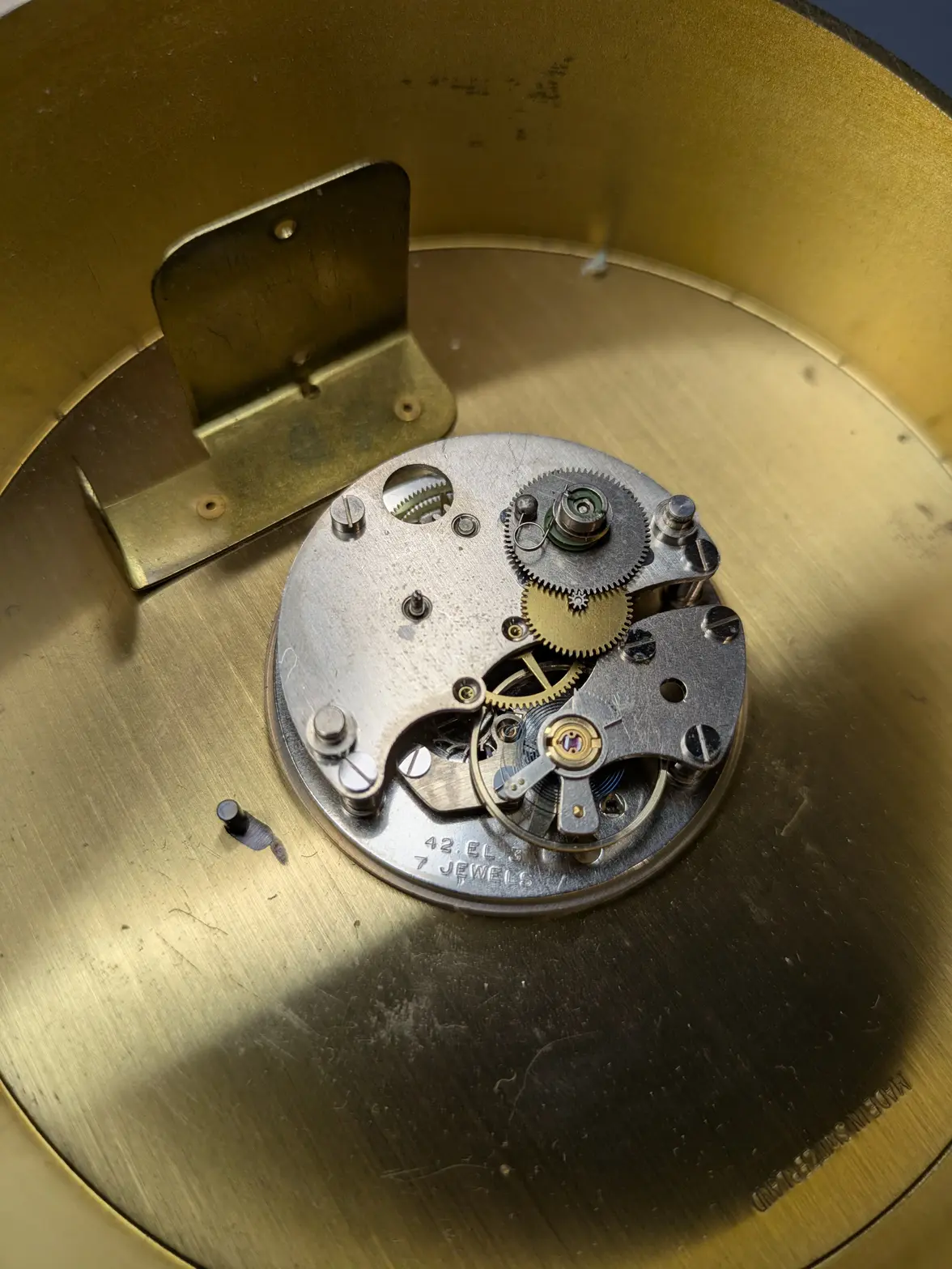

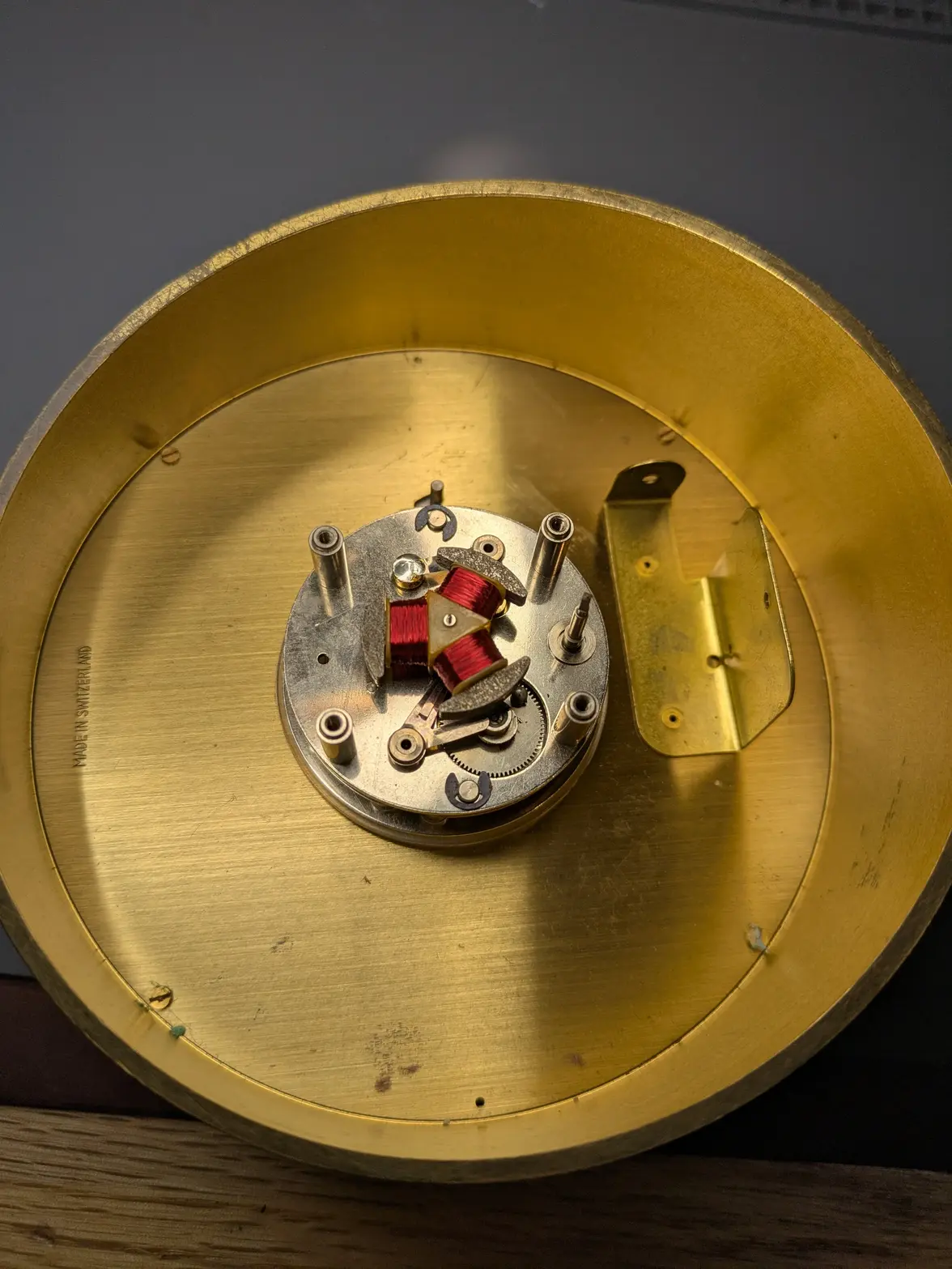

Taking it out of the case shows that the movement is in fantastic shape by all appearances, and was barely used, with no corrosion to speak of. It sets easily, so I'm excited about that!

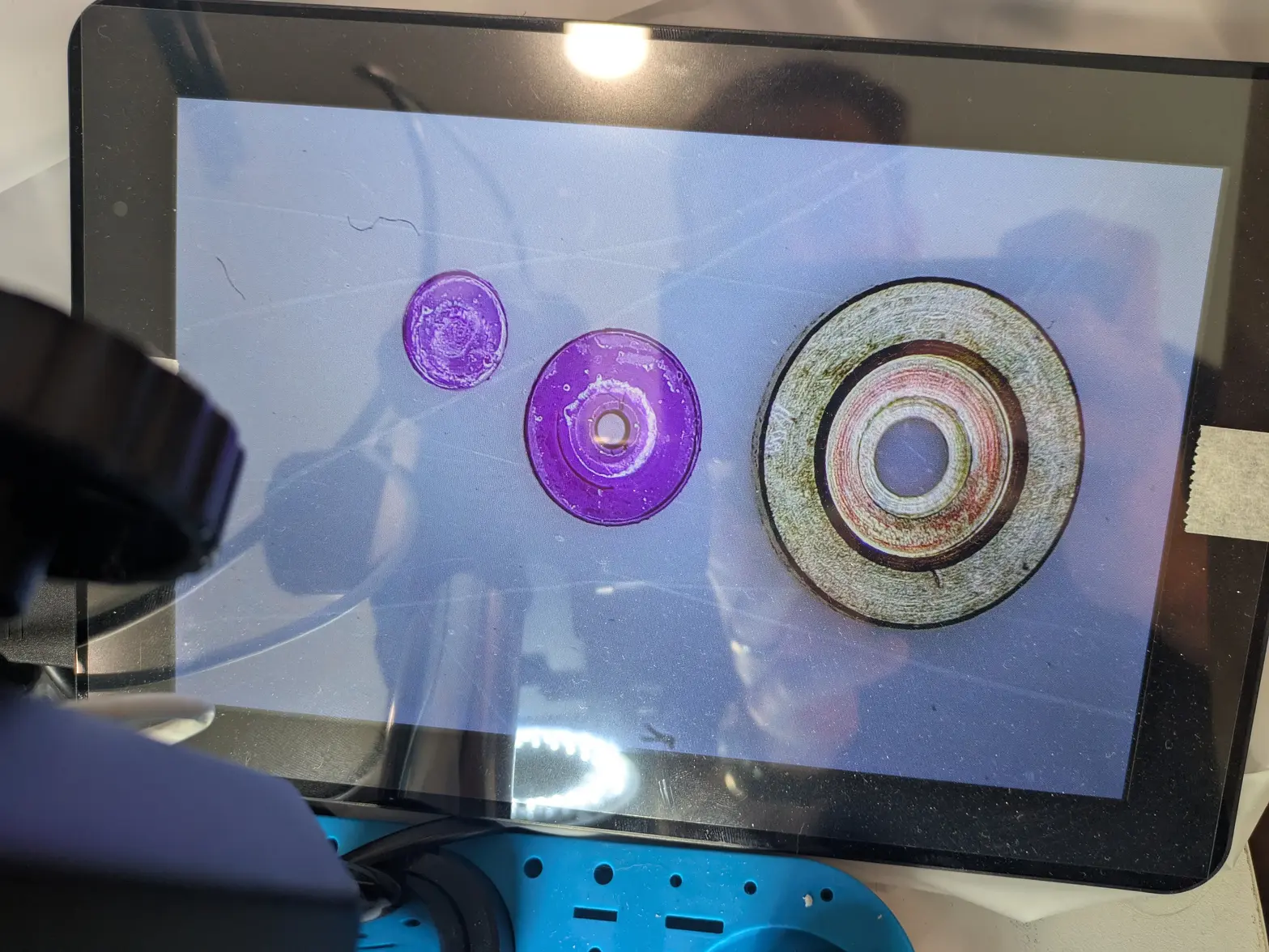

I haven't had a chance to figure out what was wrong (the google translate of the french just said 'doesnt work'), but I might have a task ahead of me!

I have however been unwilling to pay the going rate for one on Ebay.

I kept an eye out though, and found THIS one for sale on French Ebay, listed as 'doesn't work'. I submitted an insulting 'make an offer' figuring it would get rejected, and moved on with my evening. THEN, I got a message the next morning that my offer was accepted! It took a while to ship, but showed up today.

First impressions: The dial/glass/etc is in beautiful shape. The case itself is a little dirty/has some marks on it, but is otherwise pretty fantastic. I'm missing the 'rubber'-esque bottom on the body, but otherwise it seems complete (minus a 9v!).

Size wise, this is WAAAY smaller than I expected. It is about the size of a beer can, and about 2x as heavy. The base itself is a REALLY heavy guy.

Taking it out of the case shows that the movement is in fantastic shape by all appearances, and was barely used, with no corrosion to speak of. It sets easily, so I'm excited about that!

I haven't had a chance to figure out what was wrong (the google translate of the french just said 'doesnt work'), but I might have a task ahead of me!