ChrisN

·So, first clock for me to work on. It's a God awful small affair and might take a while but will share some photos in case anyone is interested.

Here's what I bought and it's a Westminster chiming Smiths (Made in England) Mantle clock. From the Fifties, I suspect, with a K6A (522) calibre. Runs for a few hours but stops.

Rear door open and you can see the hammers which strike the horizontal rods to make the chimes. Takes me back to Sundays sitting quietly (or else!) reading in my Grandfather's front room.

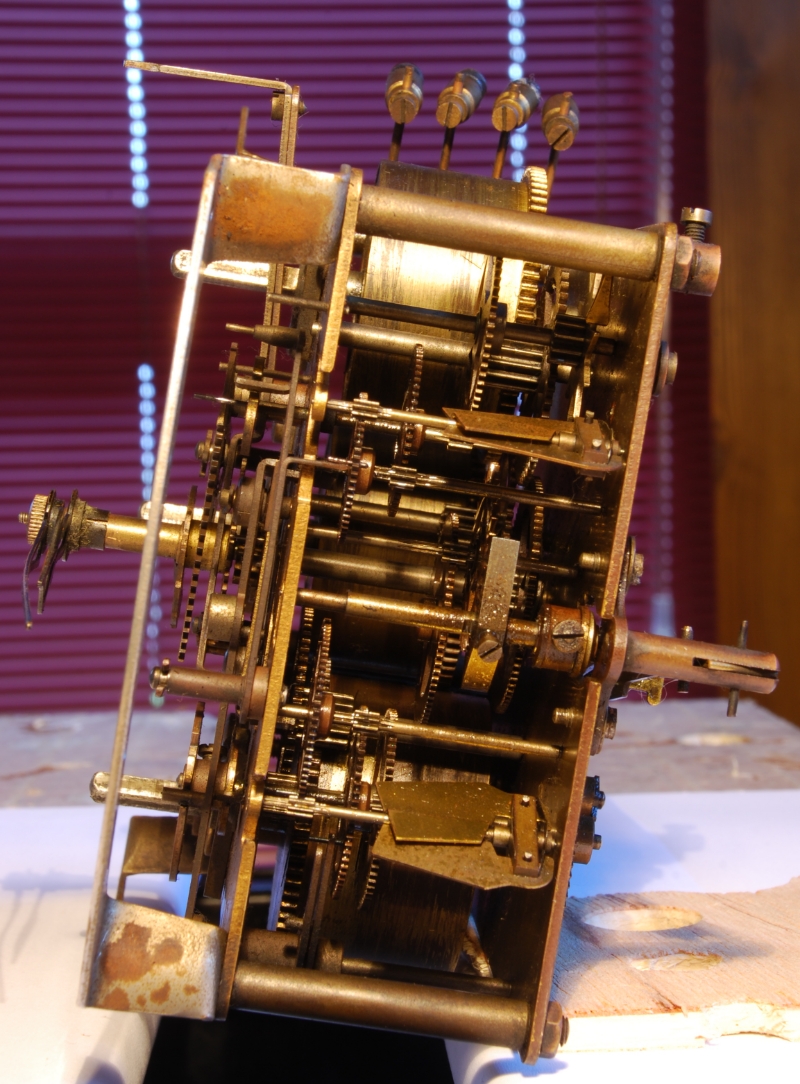

De-cased and there's a lot going on at the front plate. Three barrels and clicks at the lower. The right side and barrel run the chimes, the left the hour striking and the centre runs the clock train. The bar on the left works to turn off the chimes for night time. I've lots of photos of this at various times to realign all the parts so it strikes correctly.

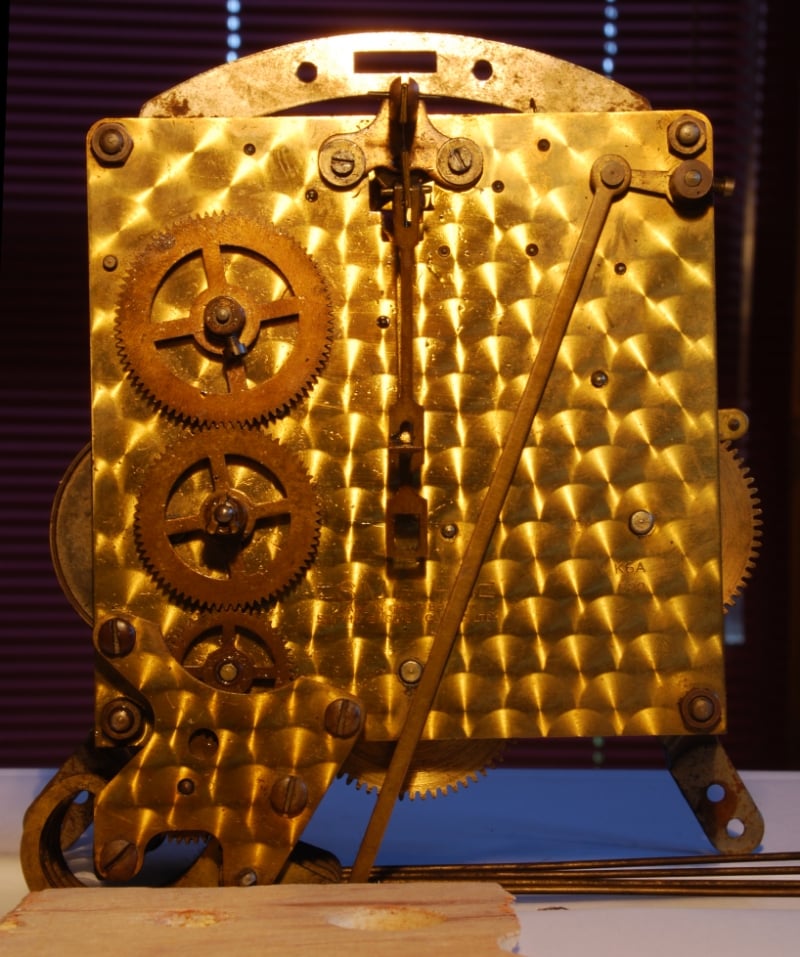

A rear view showing the train for the chimes on the left and the long bar on the right works the hour striking on three of the four notes. In the middle is where the pendulum attaches. Plenty of WD40 here....

In the top view, it's clear there are a lot of wheels!

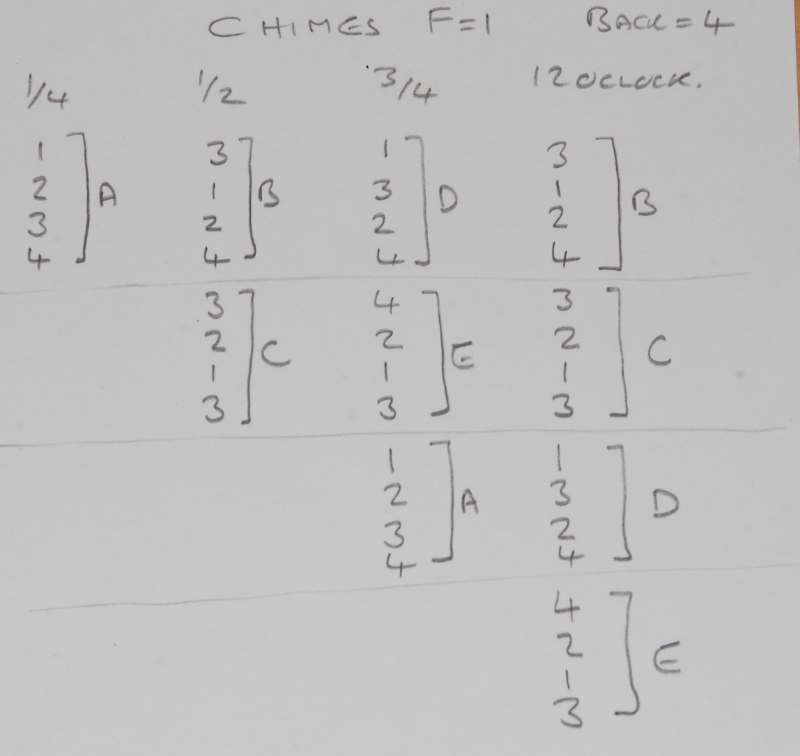

There are 4 hammers so 4 different notes and they strike in these orders (1 at the dial) with the hour counting being after the 12 O'Clock strikes using three of the notes. There are 5 different sequences so, it's pretty clever.

Front plate pretty much stripped and it's fairly clear this is dirty from the clean areas where parts have been removed. Lots of WD40 again....

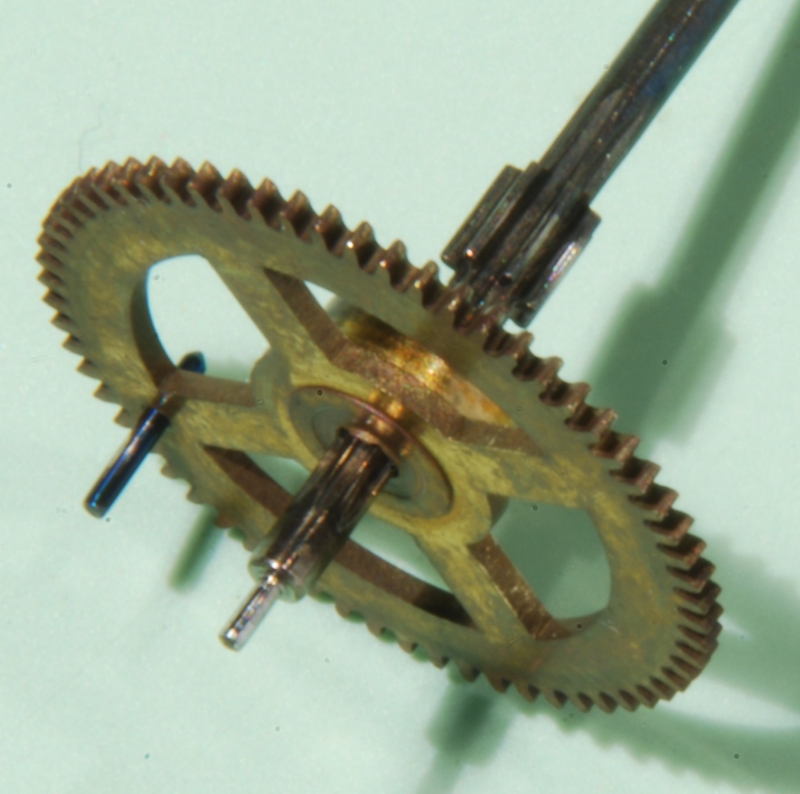

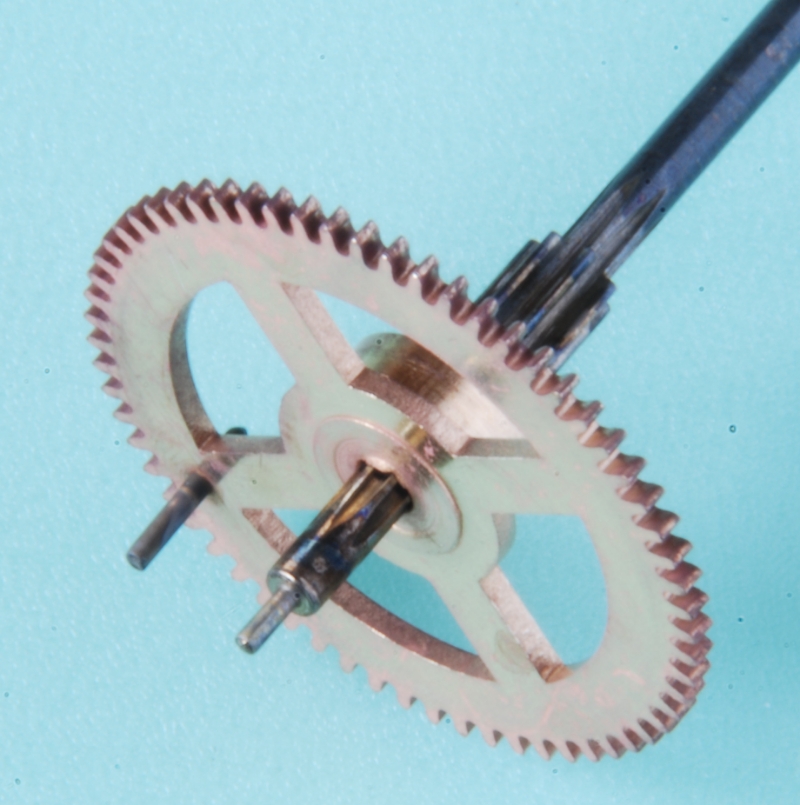

Back plate removed and these are the wheels between plates.

Lots of parts in these clocks and only 20% will fit in the cleaning machine so, lots of hand cleaning.

Good news is that there is little wear in all the pivot holes in the plates so no re-bushing required. Am struggling to separate the cannon pinion (that's what I'm calling it) so can't get the central shaft out yet.

Watch tools are useless for this scale so it's all small car tools to take it apart. Excuse for a picture of the head off the E-Type!

Two of the three springs are conical so will be buying three new springs but that's no real cost. Got to be careful with these as there is a huge energy in them and I might get a Watchmaker to install them as it's not worth buying a tool for my one clock. Will see if I can install the flat one by hand without deforming it first as then I could install all myself.

More when I've moved on.

Cheers, Chris

Here's what I bought and it's a Westminster chiming Smiths (Made in England) Mantle clock. From the Fifties, I suspect, with a K6A (522) calibre. Runs for a few hours but stops.

Rear door open and you can see the hammers which strike the horizontal rods to make the chimes. Takes me back to Sundays sitting quietly (or else!) reading in my Grandfather's front room.

De-cased and there's a lot going on at the front plate. Three barrels and clicks at the lower. The right side and barrel run the chimes, the left the hour striking and the centre runs the clock train. The bar on the left works to turn off the chimes for night time. I've lots of photos of this at various times to realign all the parts so it strikes correctly.

A rear view showing the train for the chimes on the left and the long bar on the right works the hour striking on three of the four notes. In the middle is where the pendulum attaches. Plenty of WD40 here....

In the top view, it's clear there are a lot of wheels!

There are 4 hammers so 4 different notes and they strike in these orders (1 at the dial) with the hour counting being after the 12 O'Clock strikes using three of the notes. There are 5 different sequences so, it's pretty clever.

Front plate pretty much stripped and it's fairly clear this is dirty from the clean areas where parts have been removed. Lots of WD40 again....

Back plate removed and these are the wheels between plates.

Lots of parts in these clocks and only 20% will fit in the cleaning machine so, lots of hand cleaning.

Good news is that there is little wear in all the pivot holes in the plates so no re-bushing required. Am struggling to separate the cannon pinion (that's what I'm calling it) so can't get the central shaft out yet.

Watch tools are useless for this scale so it's all small car tools to take it apart. Excuse for a picture of the head off the E-Type!

Two of the three springs are conical so will be buying three new springs but that's no real cost. Got to be careful with these as there is a huge energy in them and I might get a Watchmaker to install them as it's not worth buying a tool for my one clock. Will see if I can install the flat one by hand without deforming it first as then I could install all myself.

More when I've moved on.

Cheers, Chris

Good plan on the cleaning. Am close to changing watch cleaning fluid so will try that first but your idea sounds far easier.

Good plan on the cleaning. Am close to changing watch cleaning fluid so will try that first but your idea sounds far easier.