JimInOz

··Melbourne AustraliaWhile servicing a 98 year old Elgin recently, I had a need to obtain a donor movement. Unfortunately it didn't yield all of the parts needed, so another watch was snagged to act as a donor.

The second watch was actually in better condition so the first watch was completed "as is" and I stripped, cleaned and inspected the second and then re-assembled the train.

After ensuring that all wheels were fine and there was decent backlash I fitted the anchor and balance and gave it a wind so I could get some movement to oil the pallets.

Winding felt nice and smooth and I was starting to feel that glow of satisfaction for a job well done, when there was a sudden "whizzzz" noise and the balance stopped.

DANG!

I checked for power in the barrel (it was dead) and then took the barrel bridge off to see what had happened.

It was then that I saw the benefit of the Elgin Safety Pinion.

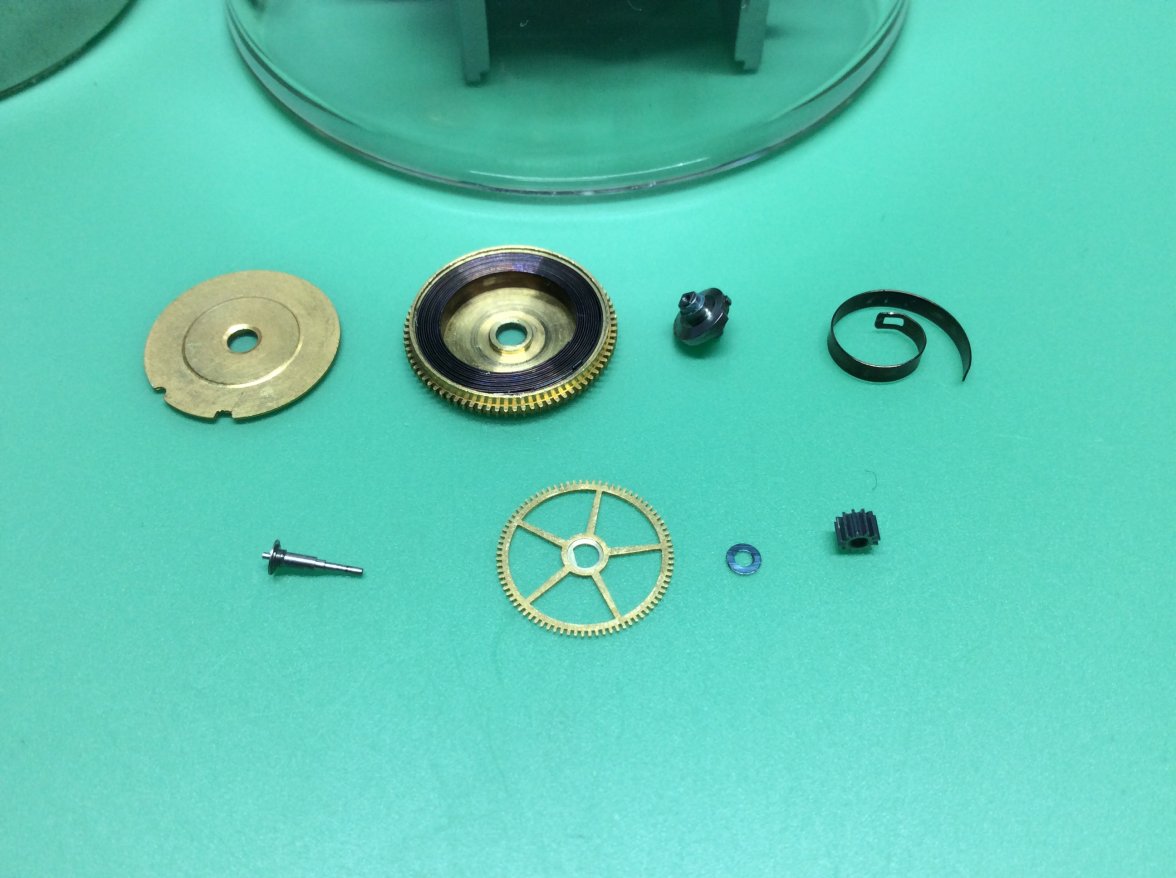

The guilty items laid out.

The problem? As I didn't have a replacement mainspring, I re-used the old blued steel mainspring and it just had enough and decided to snap.

Energy stored in a mainspring is considerable, especially in pocket watches with large springs. If the spring breaks, there is nothing to retain the barrel under tension and it usually spins at high velocity in the direction opposite to normal rotation. If this sudden reversal of energy is transmitted through the gear train it can strip teeth on the wheels and cause other damage.

To prevent this, (referring to the lower row of items from left to right in the photo below) the centre wheel shaft is keyed to the centre wheel and has a pinion that's screwed on to it (protected by a washer) with a left hand thread. (Correction, this one has a RH thread)

Under normal tension, the barrel is keeping the pinion "wound tight" on the threaded shaft. If there is a sudden change in direction from the barrel, the pinion is rapidly unscrewed from the shaft due to the direction of the thread. As soon as that happens, power from the barrel is disengaged from the centre wheel so no damage can be transmitted through the train.

So I can re-assemble the safety pinion, then use a donor spring I have (an old blued steel one), or I can order a new mainspring from the US.

Decisions decisions decisions.

Luckily I don't have to be the final arbiter, I'll leave that to the owner to do make the call (over to you Geoff).

Until the next exciting episode............

The second watch was actually in better condition so the first watch was completed "as is" and I stripped, cleaned and inspected the second and then re-assembled the train.

After ensuring that all wheels were fine and there was decent backlash I fitted the anchor and balance and gave it a wind so I could get some movement to oil the pallets.

Winding felt nice and smooth and I was starting to feel that glow of satisfaction for a job well done, when there was a sudden "whizzzz" noise and the balance stopped.

DANG!

I checked for power in the barrel (it was dead) and then took the barrel bridge off to see what had happened.

It was then that I saw the benefit of the Elgin Safety Pinion.

The guilty items laid out.

The problem? As I didn't have a replacement mainspring, I re-used the old blued steel mainspring and it just had enough and decided to snap.

Energy stored in a mainspring is considerable, especially in pocket watches with large springs. If the spring breaks, there is nothing to retain the barrel under tension and it usually spins at high velocity in the direction opposite to normal rotation. If this sudden reversal of energy is transmitted through the gear train it can strip teeth on the wheels and cause other damage.

To prevent this, (referring to the lower row of items from left to right in the photo below) the centre wheel shaft is keyed to the centre wheel and has a pinion that's screwed on to it (protected by a washer) with a left hand thread. (Correction, this one has a RH thread)

Under normal tension, the barrel is keeping the pinion "wound tight" on the threaded shaft. If there is a sudden change in direction from the barrel, the pinion is rapidly unscrewed from the shaft due to the direction of the thread. As soon as that happens, power from the barrel is disengaged from the centre wheel so no damage can be transmitted through the train.

So I can re-assemble the safety pinion, then use a donor spring I have (an old blued steel one), or I can order a new mainspring from the US.

Decisions decisions decisions.

Luckily I don't have to be the final arbiter, I'll leave that to the owner to do make the call (over to you Geoff).

Until the next exciting episode............

Edited: